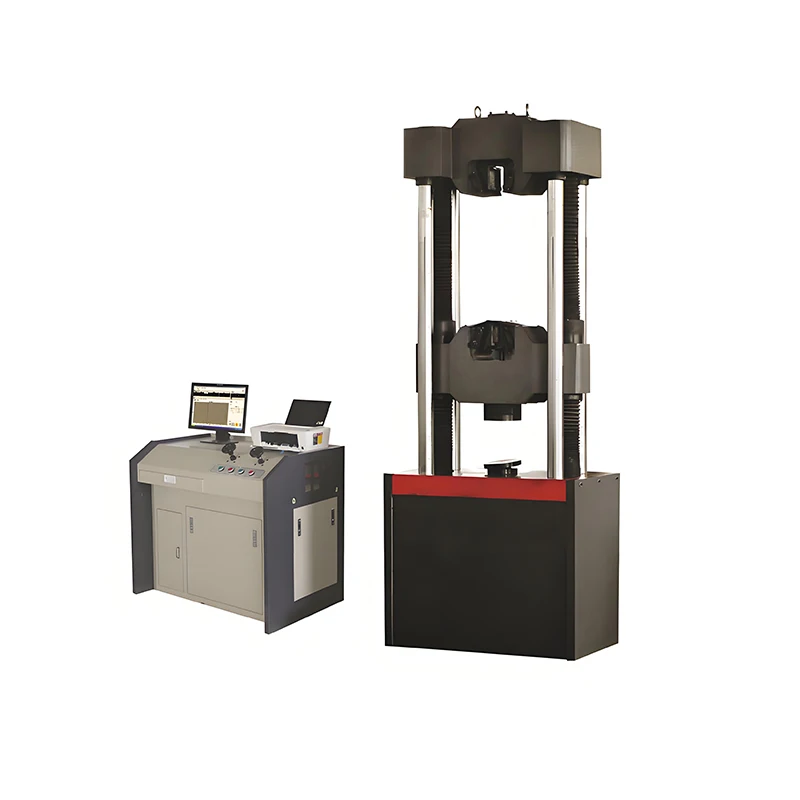

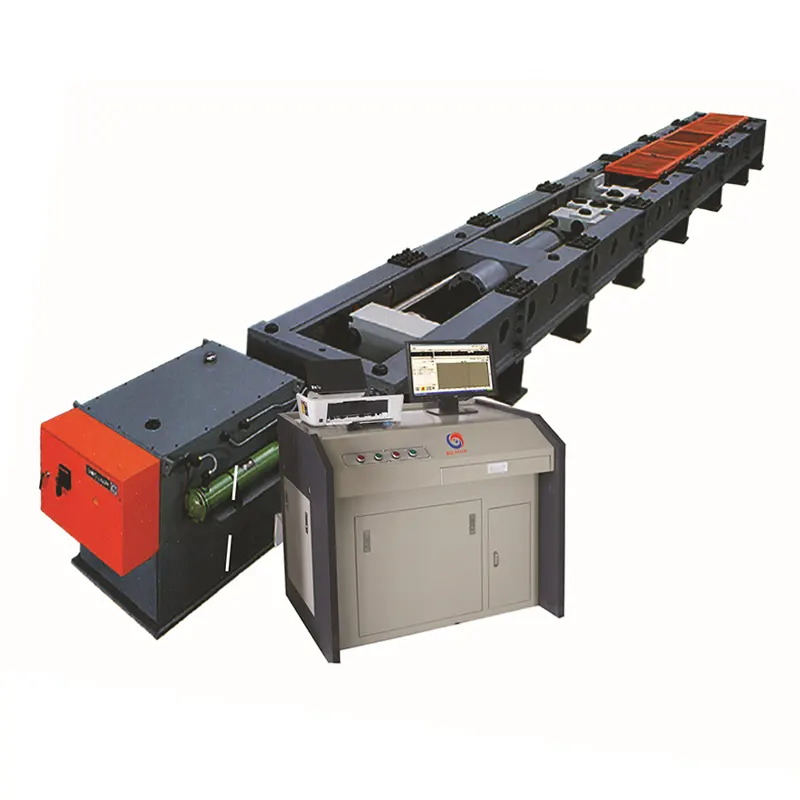

Discover the importance of a Rubber Tensile Test Machine for testing the strength, elasticity, and durability of rubber materials. Our machines provide accurate results that help in quality control and product development.

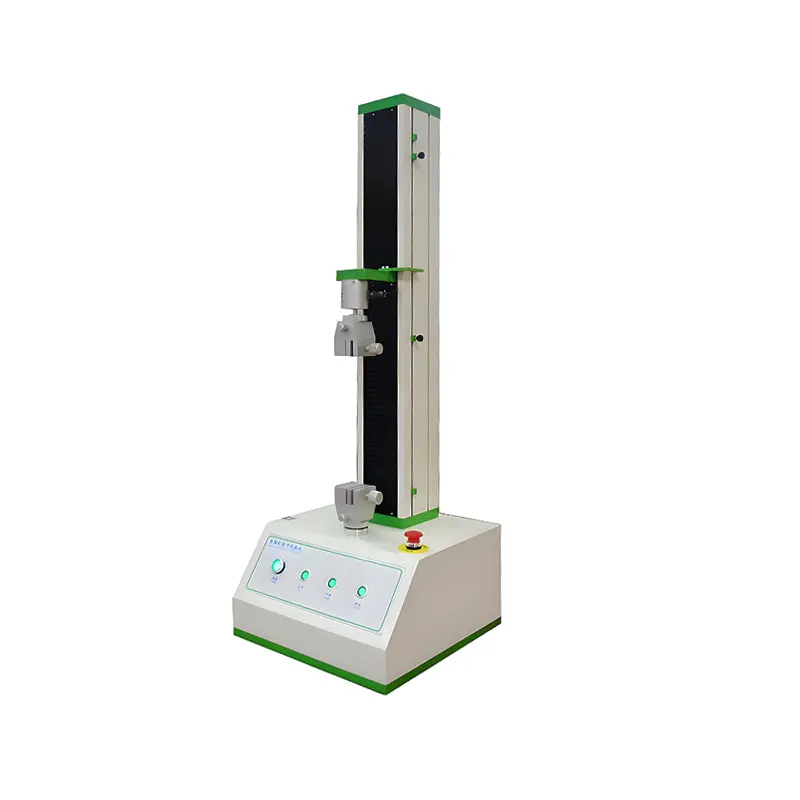

Our Rubber Tensile Test Machine is designed with state-of-the-art technology to ensure precise testing of rubber samples. This machine is essential for industries that rely on rubber products, as it helps in assessing the material's performance under various conditions. With features that enhance usability, accuracy, and reliability, our machine stands out as the best choice for professionals in the rubber industry.

Core Testing Items:

- Basic Mechanical Properties

- Tensile Strength (MPa): Maximum stress before fracture

- Elongation at Break (%): Length change rate at fracture vs. original length

- Modulus at Specific Elongation (100%, 300%): Stress at defined elongation (indicates stiffness)

- Permanent Set: Irreversible deformation ratio after stretching

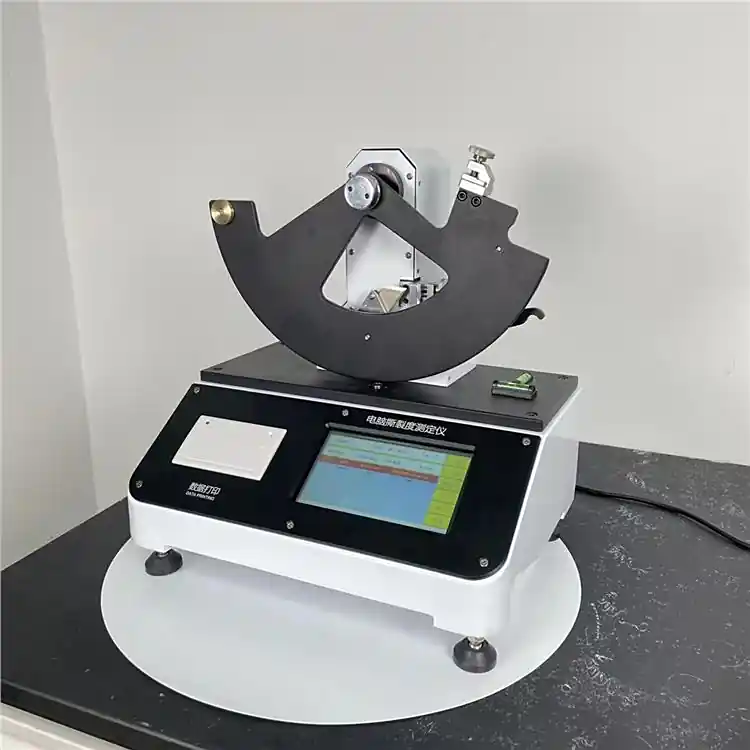

- Special Performance Analyses

- Stress Relaxation: Stress decay over time under constant strain (e.g., seal durability)

- Creep Behavior: Deformation increase over time under constant stress (e.g., suspension components)

- Elastic Modulus (Young's Modulus): Stress-strain ratio in linear deformation phase

Industry Application Scenarios

| Industry Sector | Tested Components | Compliance Standards |

|---|---|---|

| Automotive Manufacturing | Tire sidewalls, engine gaskets, suspension bushings | ISO 37, GB/T 528 |

| Medical Devices | Catheters, latex gloves, silicone implants | ASTM D412, ISO 10993 |

| Electronics & Electrical | Cable sheaths, keypad silicone, anti-vibration pads | UL 1581, IEC 60544 |

| Construction Engineering | Bridge bearing pads, waterproof membranes, expansion joint seals | GB/T 529, JT/T 4 |

| Consumer Goods | Sports shoe soles, yoga mats, diving snorkels | ISO 7619, EN ISO 1798 |

Rubber Tensile Testing Machine – Key Features

- Auto Calibration: The system automatically calibrates measurement accuracy to ensure precise readings.

- Force-Displacement Calculation: Automatically computes the corresponding force value for any given displacement.

- User-Friendly Operation: Intuitive Chinese menu interface for easy and clear operation.

- Comprehensive Testing Functions: Capable of performing tensile tests, elongation rate measurements, tear tests, peel tests, and more.

- Real-Time Dynamic Curve: Displays a dynamic force-displacement curve during the test for live monitoring.

- Automatic Data Display: Continuously shows real-time test force, peak value, and test status throughout the entire process.

- Automated Control: Once test parameters are set, the machine automatically executes the entire testing procedure.

- Fracture Detection: Automatically stops the crosshead movement upon sample breakage.

- Dual Protection System: Features both mechanical and programmable limit switches for enhanced safety.

Software Functional Features

- Auto Zeroing: The measurement system automatically resets to zero upon receiving the test start command.

- Deformation Switching: When using an electronic extensometer to measure material yield strength, the software automatically identifies material yield and provides multiple prompts to switch deformation modes.

- Result Reproduction: The software adopts a modular structure, with data storage and processing based on an MS-ACCESS database, enabling seamless integration with Office and other office software. Test results can be accessed and analyzed at any time, and data curves can be re-analyzed.

- Result Comparison: Multiple test characteristic curves can be overlaid, reproduced, and magnified in different colors for comparative analysis of sample sets.

- Language Switching: Supports seamless switching between Chinese and English without language barriers.

- Overload Protection: Automatically shuts down when the load exceeds 3–5% of the rated value; the overload protection threshold can also be customized.

- Additional Protections: Configurable over-travel and overtime protections.

- Emergency Stop: Equipped with an emergency stop switch to cut off the entire system's power supply in critical situations.

- Test Report: Reports can be directly printed or exported in PDF, Word, Excel, and other formats. Customizable report formats are also available to meet user-specific requirements.

- Limit Protection: Dual protection with programmable (software) and mechanical limits.

Testing Standards Reference Table

| Standard System | Tensile Strength | Tear Strength | Creep Testing |

|---|---|---|---|

| International | ISO 37 | ISO 34-1 | ISO 899-1 |

| Chinese National | GB/T 528 | GB/T 529 | GB/T 9969 |

| American | ASTM D412 | ASTM D624 | ASTM D2990 |

| Automotive-Specific | SAE J200 | — | GMW 14688 |

Multiple protections: The system is equipped with overcurrent, overvoltage, overspeed, undervoltage, undercurrent and other protections; the crosshead stroke has three-level protection including program-controlled limit, extreme limit and software limit; the load sensor has over-range protection; in case of emergency, emergency braking can be performed.