Understanding Packaging Clamping Force

What is clamping force in packaging

Clamping force in packaging refers to the pressure applied to secure a package’s closure or hold materials together during production, transportation, and storage. This force ensures that the package maintains its shape, protects the contents, and prevents damage or contamination.

Types of clamping forces

- Static clamping force: A constant pressure applied to keep the packaging sealed or fixed in place without movement. It’s crucial for maintaining package integrity over time.

- Dynamic clamping force: Variable pressure applied during packaging processes such as sealing or forming, which changes throughout the operation.

Common packaging applications requiring clamping force testing

Clamping force plays a vital role in various packaging formats, and testing ensures these packages can withstand real-world handling:

- Cartons: Proper clamping prevents crushing and deformation during stacking and transit.

- Shrink wraps: Correct clamping force ensures the wrap fits tightly without damaging the product.

- Blister packs: Consistent pressure is necessary to seal the plastic pouch securely to the backing card, protecting the contents and ensuring tamper resistance.

Accurate packaging force measurement guarantees that these applications deliver durability, safety, and product integrity throughout the supply chain.

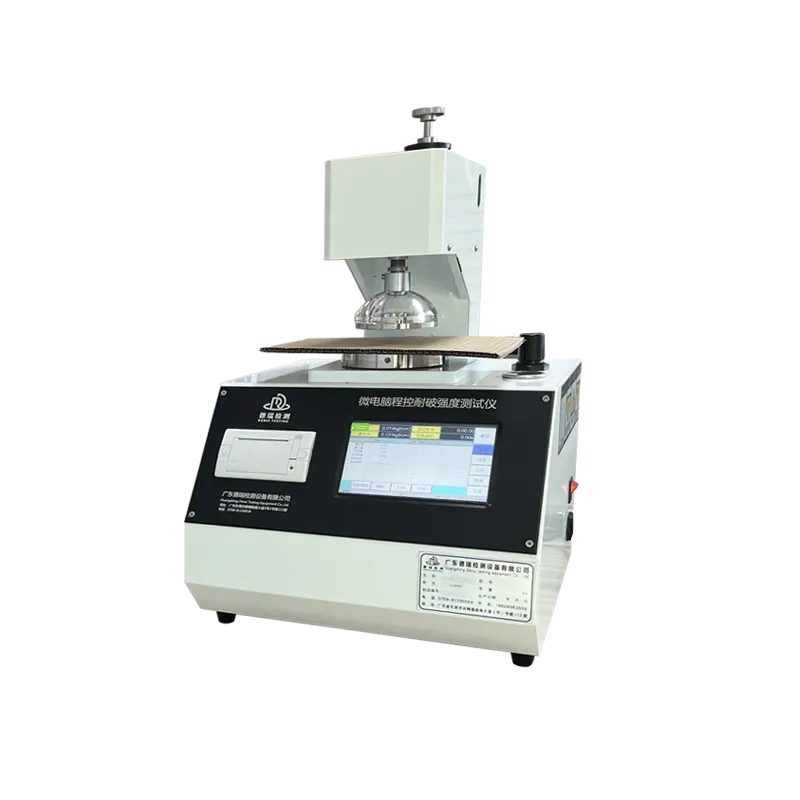

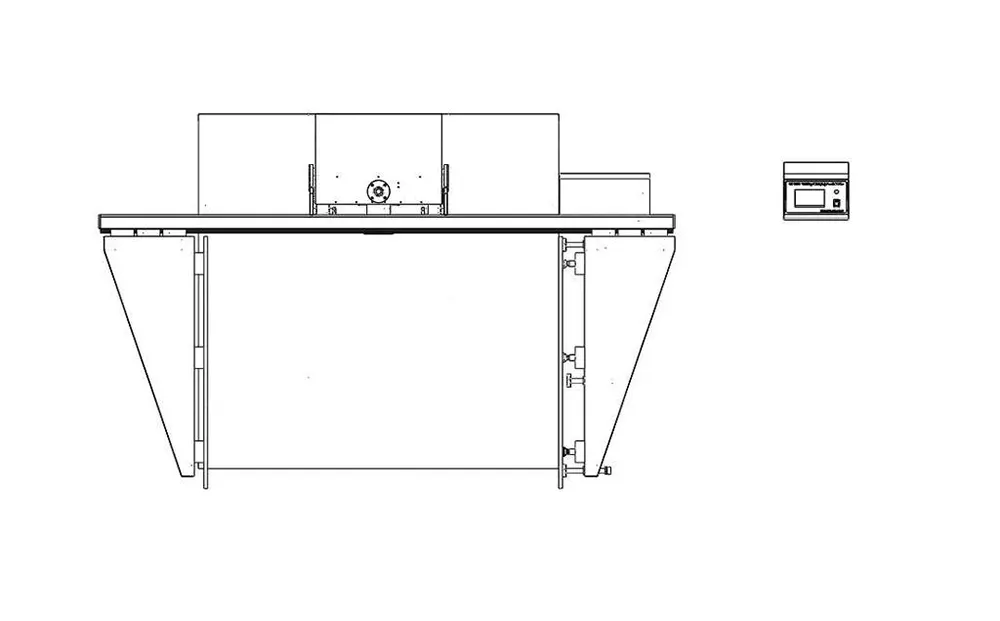

What is a Packaging Clamping Force Testing Machine

A Packaging Clamping Force Testing Machine is a device designed to measure the pressure or force applied by packaging machinery when clamping boxes, shrink wraps, blister packs, and other materials. Its main function is to ensure that the clamping force is just right—not too tight to damage the product and not too loose to risk package failure during shipping.

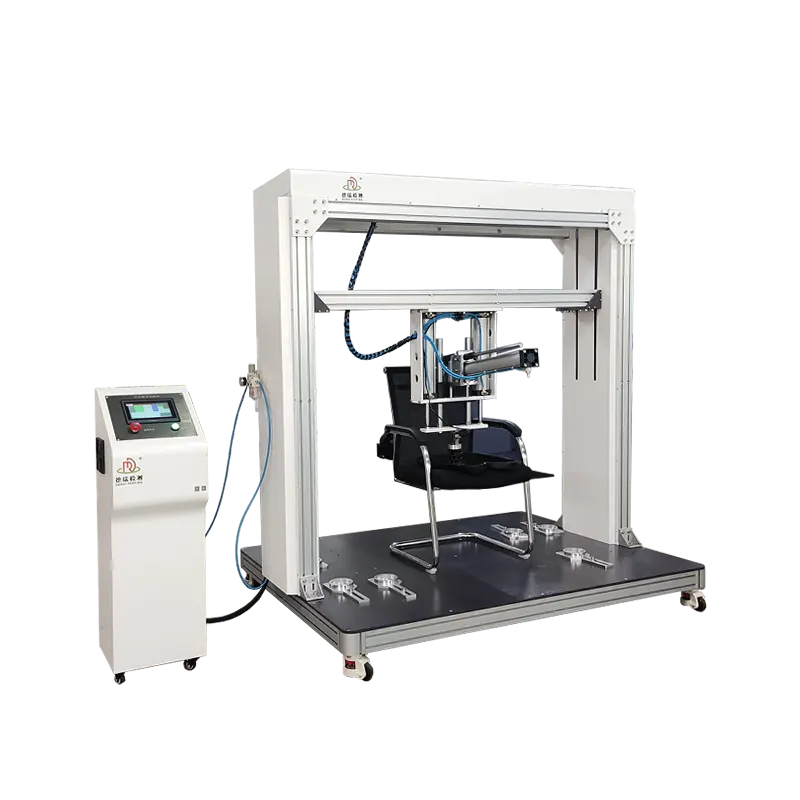

Key Components and Working Principle

- Force Sensor or Load Cell: Measures the exact clamping pressure applied.

- Control Unit: Allows users to set test parameters and displays force readings.

- Clamping Arm or Fixture: Mimics the packaging machine’s grip on the sample.

- Data Interface: Records measurements for analysis and quality control.

The machine works by applying controlled clamping pressure on a test sample. It then records the force needed to achieve a secure hold, producing a pressure-deformation curve or similar data. This data helps verify if packaging is up to standards and can withstand handling stress.

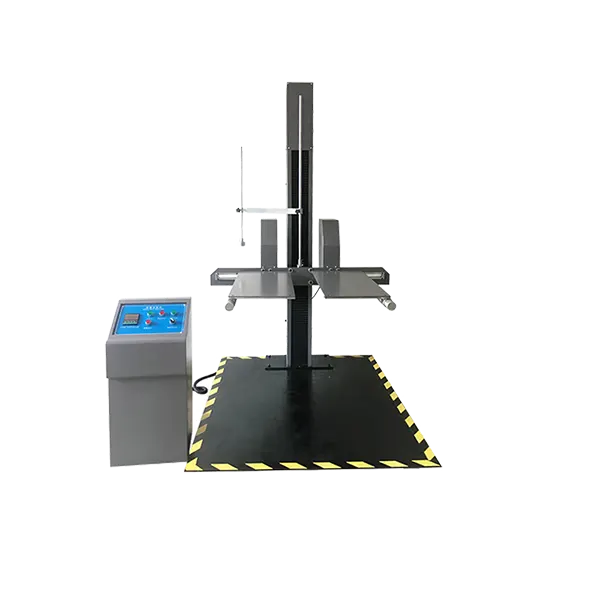

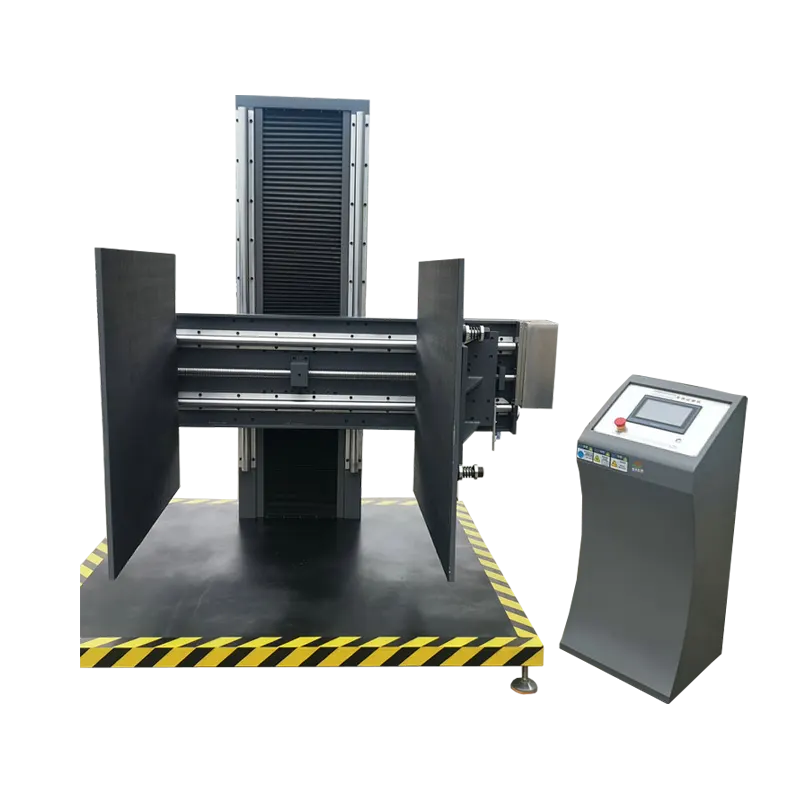

Types of Clamping Force Testers

- Manual: Operators manually apply and measure clamping force. Suitable for simple, low-volume tests.

- Semi-Automatic: Combines manual setup with automated force application and measurement for better accuracy and repeatability.

- Fully Automatic: Runs the entire testing process from start to finish with minimal human input. Ideal for high-volume packaging lines requiring fast, consistent results.

Each type fits different business needs, depending on testing frequency, accuracy demands, and budget. Using the right clamping force tester machine helps maintain packaging quality and reduces product damage risks during distribution.

Importance of Testing Clamping Force in Packaging

Testing clamping force is critical to keep products safe and intact during shipping and handling. Too little force can let packages shift or open, risking damage or loss. Too much force can crush or deform packaging, damaging the product inside.

Proper clamping force testing helps:

- Ensure product safety and integrity – It verifies the right pressure is applied to hold the package securely without harm.

- Prevent over or under clamping damage – Avoids costly packaging failures caused by improper force settings.

- Enhance packaging machine performance – Regular testing keeps machinery working efficiently and reduces wear and tear, extending equipment life.

- Comply with industry standards – Many industries require documented clamping force tests to meet quality and safety regulations, like ISTA standards.

Overall, accurate clamping force testing protects your products, cuts down waste, and boosts packing line reliability.

Features and Specifications to Consider

When choosing a packaging clamping force testing machine, it’s important to focus on these key features:

Force Range and Accuracy

- Should match the clamping forces typical in your packaging process

- High accuracy ensures reliable force measurement and packaging quality control

Test Speed and Repeatability

- Fast testing helps increase your throughput

- Consistent results each time improve confidence in your packaging machinery performance

Compatibility with Packaging Types

- Must handle your specific materials—cartons, shrink wrap, blister packs, etc.

- Versatile machines cover a range of package sizes and styles

Data Logging and Software Integration

- Ability to save and analyze test data for quality tracking

- Software connectivity supports process optimization and compliance reporting

Calibration and Maintenance

- Easy calibration keeps the tester precise over time

- Low maintenance design reduces downtime and service costs

Here’s a quick overview:

| Feature | Why It Matters |

|---|---|

| Force Range & Accuracy | Matches packaging forces, reliable tests |

| Test Speed & Repeatability | Speeds up testing, consistent results |

| Packaging Compatibility | Works with your specific materials |

| Data Logging & Integration | Tracks quality, helps in process control |

| Calibration & Maintenance | Keeps accuracy, reduces downtime |

How to Choose the Right Packaging Clamping Force Testing Machine for Your Business

Picking the right packaging clamping force testing machine starts with understanding your packaging process and product needs. Here’s what to consider:

Assess Your Packaging Process and Products

- Type of packaging: Are you testing cartons, shrink wraps, blister packs, or others? Different packaging needs different clamping force ranges.

- Volume and speed: Do you need a machine for low-volume manual tests or high-speed automated lines?

- Material sensitivity: Some products require precise force control to avoid damage during testing.

Key Questions to Evaluate Your Testing Requirements

- What’s the required force range and accuracy?

- Do you need data logging and software integration?

- Is portability or fixed installation more suitable?

- What testing standards or certifications must your machine comply with (e.g., ISTA 3A/3B)?

Cost Versus Value Considerations

- Balance initial investment with long-term savings through durability and fewer product damages.

- Factor in maintenance costs and ease of calibration.

- Consider machines that offer customizable features to match your packaging needs.

Why Choose Derui’s Solutions

Derui offers tailored packaging clamping force testing machines designed to fit diverse production environments. Their key benefits include:

- Customization to match your packaging types and production speeds.

- Reliable accuracy for consistent, repeatable results.

- Strong after-sales support including training, maintenance, and upgrades.

| Factors | What to Look for | Derui Advantage |

|---|---|---|

| Packaging Type | Compatibility with cartons, wraps etc. | Custom-fit options |

| Force Range & Accuracy | Meets required pressure and precision | High precision sensors |

| Automation Level | Manual, semi-automatic, or fully auto | Flexible machine models |

| Data & Software | Real-time logging and analysis | Integrated, user-friendly software |

| Support & Maintenance | Easy calibration and quick support | Expert after-sales team |

Step by Step Guide to Using a Packaging Clamping Force Testing Machine

Preparing the Sample Package

Make sure your sample package is sealed and ready just like it would be for shipping. Check for any visible damage or inconsistencies. Use the exact packaging type you want to test—whether it’s a carton, shrink wrap, or blister pack—to get accurate clamping force measurement results.

Setting Up the Machine Parameters

Set the force range based on your packaging type and testing needs. Adjust test speed and clamping stroke according to the packaging material and industry standards you follow. Make sure the machine is calibrated and the software settings match your specifications for reliable results.

Conducting the Test Safely and Efficiently

Place the sample securely between the clamps. Start the test smoothly, watching for any unusual noises or movements. Always follow safety guidelines and keep hands clear during operation. The tester will apply the set clamping force to measure pressure-deformation and gather data accurately.

Interpreting the Test Results for Process Optimization

Once the test is done, review the force curve and pressure-deformation data. Look for signs of over-clamping, under-clamping, or package deformation. Use the results to tweak your packaging process—this can help improve product safety during transit and extend your packaging machine’s lifespan. Regular testing and analysis keep your packaging quality consistent and compliant.

Case Studies and Applications Derui’s Clients Success Stories

Many industries across the U.S. have seen real benefits using Derui’s Packaging Clamping Force Testing Machine. From food and beverage to electronics and pharmaceuticals, companies rely on accurate clamping force measurement to keep their packaging consistent and reliable.

For example, a major beverage company used Derui’s clamping pressure testing to fine-tune their carton sealing process. This helped reduce damaged products during shipping by 30%, saving thousands in replacement costs. Another client in the medical device sector improved packaging integrity for blister packs, meeting strict ISTA 3A standards and passing safety audits with ease.

Derui’s testing machines also helped a shrink wrap manufacturer optimize their packaging force, balancing product protection without over-clamping. This adjustment led to fewer packaging failures on the line and lower material waste.

Across the board, companies report measurable improvements such as:

- Enhanced packaging quality and consistency

- Reduced product damages and returns

- Improved packaging line efficiency

- Lower packaging material waste

- Clear data for compliance and quality control audits

Derui’s solutions deliver reliable, customizable clamping force testing that fits multiple packaging types and industry needs, driving cost savings and peace of mind for U.S. businesses.

Frequently Asked Questions FAQs

How often should testing be done

Regular testing depends on your production volume and packaging type. For most businesses, running clamping force tests weekly or monthly helps catch issues early. If you’re dealing with sensitive products or changing materials often, consider testing more frequently to keep packaging integrity consistent.

Can the machine test all packaging materials

Most packaging clamping force testing machines, including Derui’s, can handle a wide range of materials—cartons, shrink wraps, blister packs, and more. Make sure to check the tester’s compatibility with your specific packaging types to get accurate and reliable results every time.

What maintenance measures ensure machine longevity

Keeping your clamping force tester in good shape is simple:

- Calibrate regularly according to the manufacturer’s guidelines

- Clean moving parts and sensors to avoid buildup

- Check for wear and tear on clamps and replace parts as needed

- Keep software updated if your machine includes digital features

Proper maintenance helps maintain accuracy and extends your machine’s lifespan.

How to troubleshoot common issues

If you notice inconsistent readings or machine errors, consider these quick checks:

- Verify calibration is up to date

- Inspect clamps for damage or misalignment

- Ensure samples are prepared correctly with no external interference

- Restart the machine to reset any software glitches

- Consult the user manual or contact support if problems persist

Being proactive with troubleshooting keeps your packaging force measurement smooth and reliable.