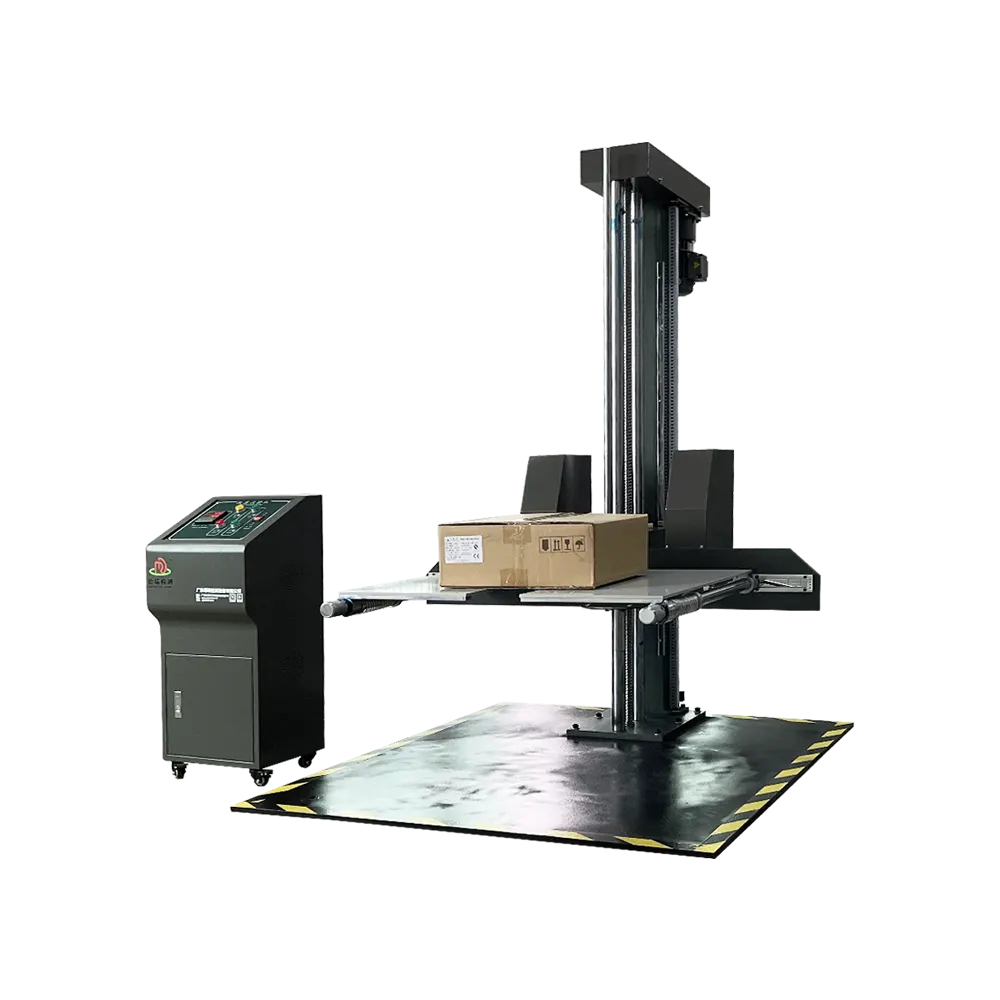

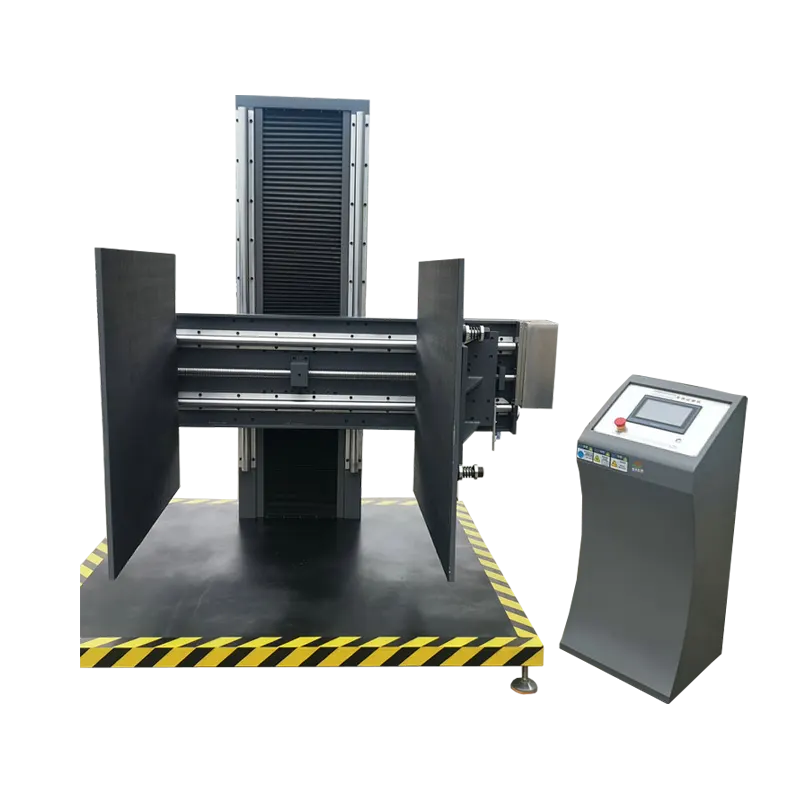

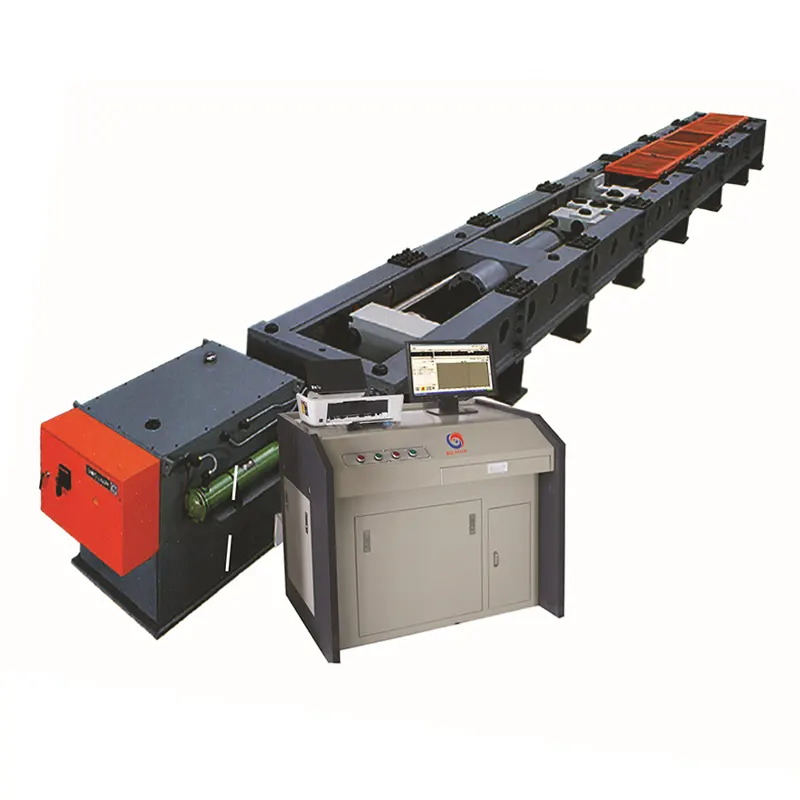

The simulation transportation vibration testing machine is manufactured based on the transportation standards of the United States and Europe, and improved by referring to similar equipment from the United States. It simulates the vibration and collision of goods during transportation by automobiles or ships through the elliptical motion trajectory generated by the eccentric bearing during rotation. The test platform is fixed on the eccentric bearing. When the eccentric bearing rotates, the entire plane of the test platform will move up and down and back and forth in an elliptical motion. Adjusting the rotation speed of the eccentric shaft is equivalent to adjusting the traveling speed of the automobile or ship.

The ISTA test standard is the American Transportation Association standard, and ASTM is the American Materials Association standard. Both standards have the same requirements for the equipment used to simulate transportation vibration: amplitude of 25.4mm (1 inch, fixed), frequency of 1.5 - 5Hz (or 100 - 300 revolutions per minute, adjustable). The test basis is: T = 14200/CPM (based on a total vibration count of 14200 times), and the test speed selection method.

The table of test methods related to ISTA/ASTM standards is as follows:

Test speed (CPM): 150, 180, 210, 240, 270, 300

Corresponding frequency (Hz): 2.5, 3.0, 3.5, 4.0, 4.5, 5.0

Test time (min): 95, 79, 66, 60, 53, 48

Product Usage:

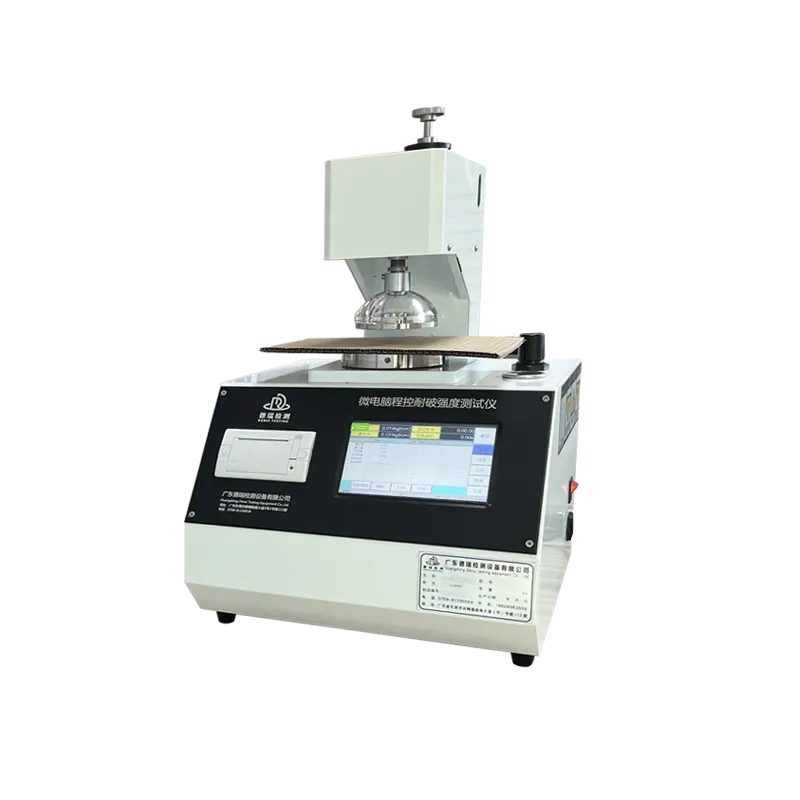

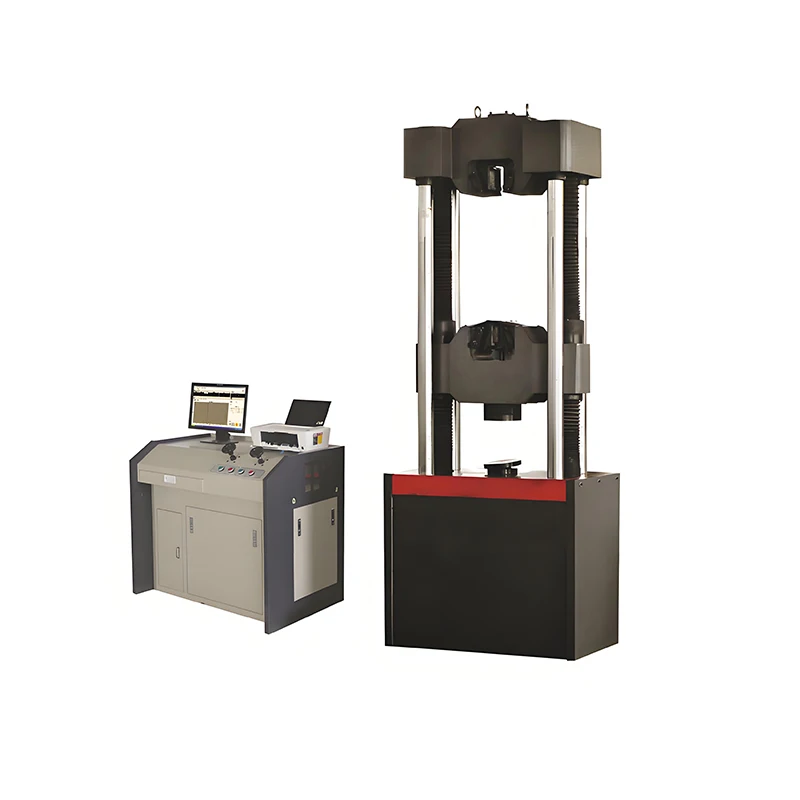

The simulation transportation vibration test bench is suitable for vibration tests of toys, electronics, furniture, gifts, ceramics, communication equipment, apparatus, computers and auto parts, etc. It is used to inspect their transportation endurance or uniform durability. The digital instrument displays the vibration frequency; the synchronous silent belt drive ratio; the test sample clamping adopts the guide rail type, which is convenient and safe to operate; the machine base uses heavy-duty channel steel with vibration damping rubber pads, which is easy to install, runs smoothly and does not require installation of anchor bolts; the DC motor speed regulation ensures stable operation and strong load capacity. It is a simulation environmental test, simulating the environment of products in the transportation state, and evaluating the rationality of product packaging design and the structural strength of the product itself. It complies with EN71, ANSI, UL, ASTM, ISTA and other test standards.

Equipment features:

1、The cabinet is treated with electrostatic baking varnish, and the tabletop is made of stainless steel wear-resistant plate. The whole machine is reasonably designed, with a firm structure, safe and stable operation, and meets the testing requirements.

2、Adjustable and displayable speed and time, humanized design;

3、It adopts a synchronous belt drive reduction system, which is low in noise.

4、The unique slide rail structure design makes it convenient and reliable to clamp products.

5、The base is equipped with heavy-duty channel steel and anti-vibration rubber pads at the four corners, making installation convenient and operation smooth.

6、The variable-speed DC motor operates smoothly and has a strong load capacity.

Multiple protection devices:

1.Mechanical limit switches protect the upper and lower limit travel.

2. In case of emergency, the emergency stop switch provides braking protection.

3.Overcurrent, overvoltage, undervoltage, undercurrent, leakage and overload protection.

4. Software overload limit protection

5. Breakpoint shutdown protection

Safety Precautions:

1: Installation and Structure: This testing machine is delivered as a complete assembly and does not require installation by the customer.

2:This testing machine is only applicable to single-phase 220V AC power supply.

3:When the machine is running, do not touch any part except the control panel with your hands to avoid scratches or pinches.

4: If it is necessary to move the machine, make sure to cut off the power supply and wait for 5 minutes for it to cool down before operating.