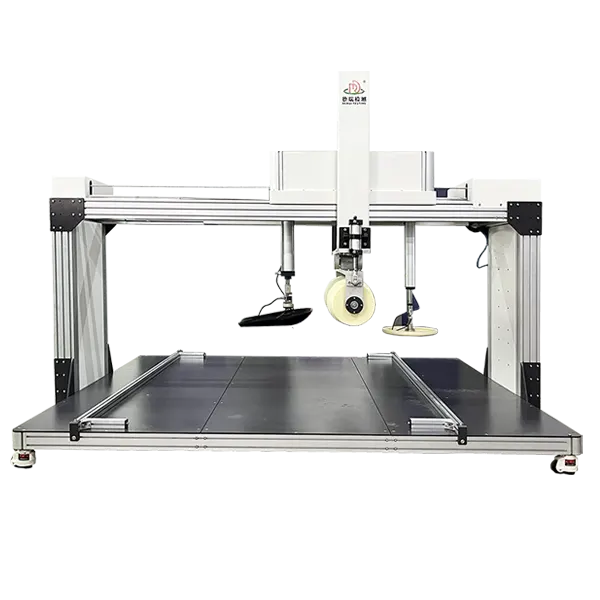

The office chair backrest repeated test machine (pull-back type) (office chair backrest repeated test machine, office chair backrest test machine, office chair backrest fatigue test machine) is suitable for testing the life of the chair's backward tilting mechanism, simulating its strength or endurance capacity under one-time or repetitive loads during normal use and habitual misuse. It is used to inspect the strength of the product under repeated use and repeated loading conditions.

Our Office Chair Backrest Repetitive Test Machine is engineered for precision, durability, and reliability. With the ability to test various designs and materials effectively, this machine simulates repeated stress on office chair backrests to ensure that they meet industry standards. From initial design validation to final production testing, our machine is essential for any manufacturer looking to ensure their products are built to last.

Product Features:

- This device is a multi-functional testing equipment that can choose between cylinder output force or displacement.

- The output angle of the cylinder can be changed by sliding the position of the fixed pulley.

- The loading pad is bound to the back of the chair and connected to the cylinder through a webbing. After the cylinder is unloaded, the back of the chair will naturally return to its original state relying on its own elasticity.

- The precise manual pressure regulating valve ensures the stability and reliability of the cylinder output force, and the output force value of the cylinder is digitally displayed.

- The L-shaped baffle and L-shaped pressure plate are used to fix the test sample, and the manual screw keeps it tightly pressed.

- It has an RPM speed display and can be continuously adjusted.

- Equipped with a touch screen and PLC, it has the functions of power-off memory and stop at the breakpoint.

Main functions:

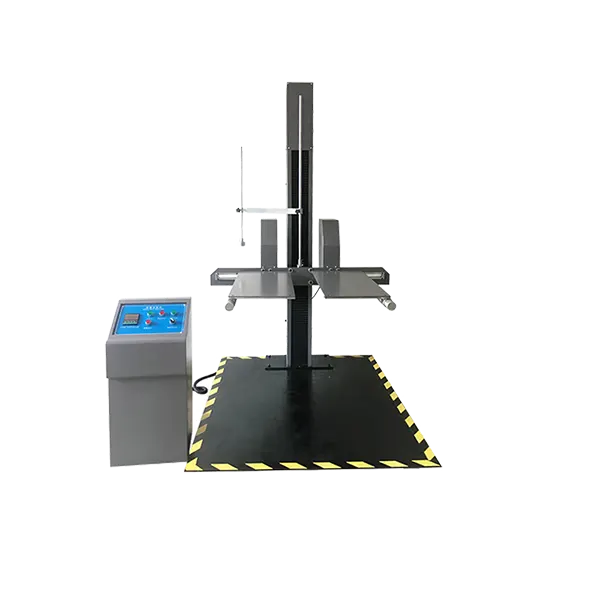

1.Back structure strength test: Test the strength of the office chair's back frame and support structure, evaluate its load-bearing capacity and structural stability under force, and ensure that the backrest does not break or deform due to excessive load during normal use.

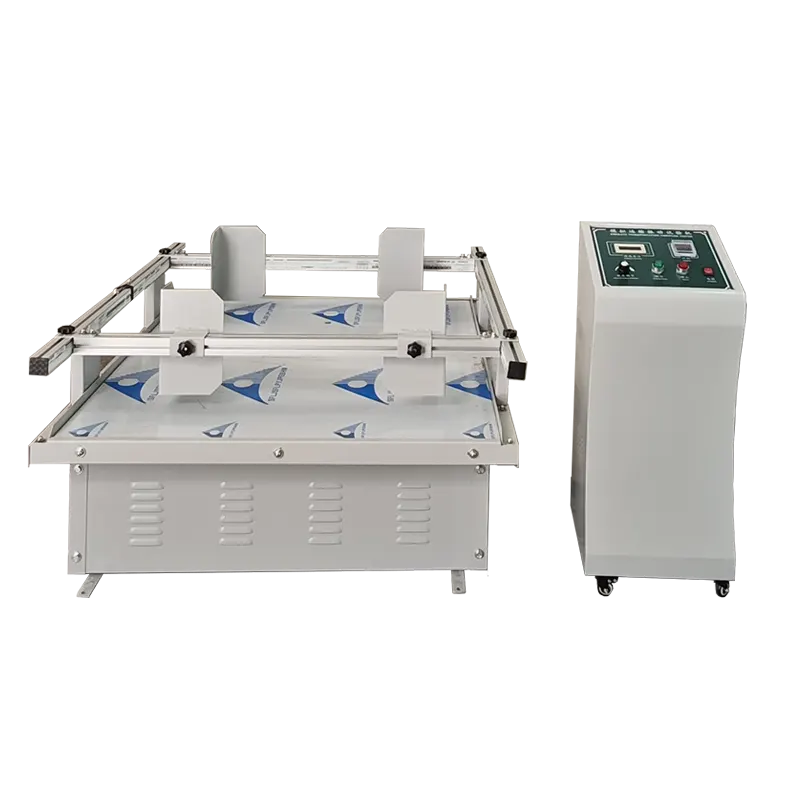

2.Back material durability assessment: Assess the durability of the materials used in the office chair's back (such as plastic, metal, or composite materials) under tension and compression, including the material's strength, elasticity, and deformation degree.

3.Durability test of connecting parts and fastening devices: Test the durability of the connecting parts and fastening devices that connect the back frame to the seat of the office chair, ensuring that the connecting parts do not loosen or break during long-term use.

4.Static and dynamic load tests: Apply static and dynamic loads to the office chair's back, evaluate its deformation and structural stability under different loads, and simulate the user's daily usage conditions.

Ergonomics and comfort assessment: Evaluate the ergonomics and comfort of the office chair's back design, ensuring that the backrest provides appropriate support for the waist and back, and avoids discomfort or posture problems caused by long-term use.

5.Safety assessment: Assess the safety performance of the office chair's back during use, including the absence of sudden breakage or structural loosening when subjected to the maximum recommended load, to ensure user safety.

Comply with standards:

Comply with the relevant requirements of QB/T 2280-2007, BIFMA X5.1-2011, EN 1335:2000, and QB/T 2602-2013 standards.

Applicable objects:

Furniture manufacturing enterprises: raw material incoming inspection, finished product random inspection on production lines, new product R&D verification.

Third-party quality inspection agencies/laboratories: Provide authoritative certification test reports.

Research institutes/universities: Conduct research on the mechanical properties of furniture and material testing.

Large-scale purchasers (such as office furniture buyers): for evaluating supplier products.