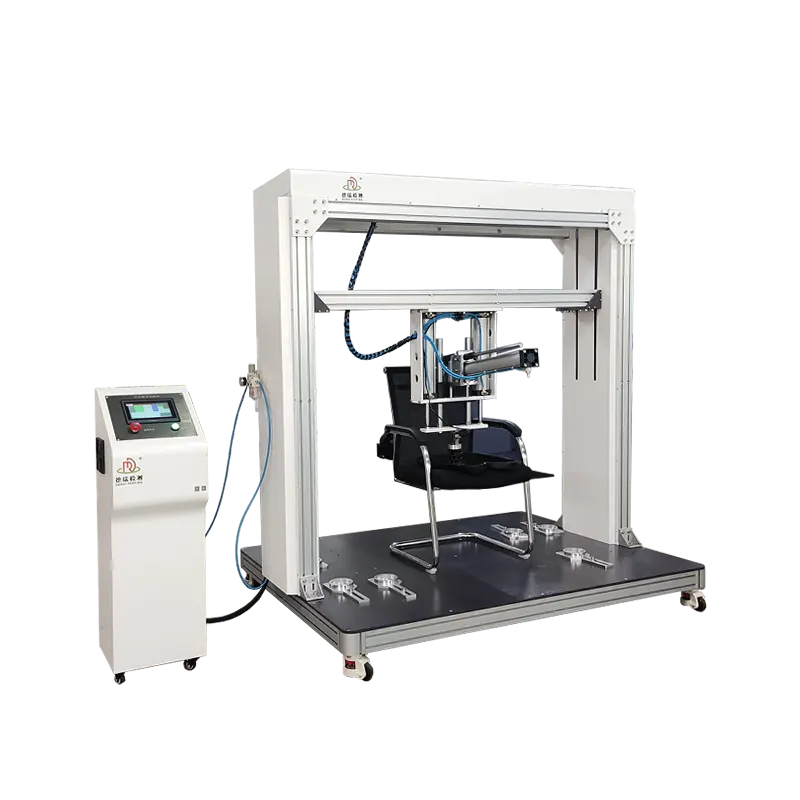

Foam Dynamic Fatigue Tester: Precision Durability Testing for Foam Materials

Experience unmatched accuracy with our Foam Dynamic Fatigue Tester, designed for rigorous, repeatable fatigue testing of PU foam, latex, sponge, and flexible cellular materials. Featuring a robust constant force pounding system and user-friendly PLC interface, it delivers precise results that meet ISO 3385 and ASTM D3574 standards.

Key Specs:

- Cycle rate: Up to 60 cycles/minute

- Force range: Adjustable up to 1000 N

- Indenter sizes: Multiple interchangeable options

- Sample dimensions: Supports various foam thicknesses

- Noise reduction technology for quiet operation

Ready to boost your foam durability analysis?

👉 Schedule Your Demo Today and see how our Foam Dynamic Fatigue Tester can transform your testing process!

Overview and Applications

The Foam Dynamic Fatigue Tester is built to evaluate how well foam materials stand up to repeated pushing and pounding over time. It simulates real-life wear by applying dynamic compression cycles to various foam types like PU foam, latex foam, sponge, and other flexible cellular materials. This tester helps you measure foam durability, resilience, and fatigue resistance, making it ideal for quality control, R&D, and production lines.

Target Materials

- Polyurethane (PU) foam

- Latex foam

- Upholstery foam

- Sponge

- Flexible cellular polymers

Industry Uses

This machine is widely used in industries such as furniture, automotive seating, bedding, packaging, and footwear, where foam longevity is crucial. It supports manufacturers in ensuring products meet durability standards and customer expectations.

Visual Aids

To help you see the tester in action, we provide high-quality demo videos and clear industry icons showcasing its role in key sectors like automotive, furniture, and bedding. This transparency helps you understand exactly how the Foam Fatigue Testing Machine will fit your testing needs.

Key Features and Benefits

Our Foam Dynamic Fatigue Tester is built with precision and ease of use in mind. Here’s what makes it stand out:

Precision Control Systems

- Accurate force application ensures consistent, reliable test results.

- Adjustable cycle rates let you fine-tune tests for different foam types.

- Real-time monitoring keeps tests on track without any guesswork.

User-Friendly PLC Interface

- Simple touchscreen controls that anyone can learn quickly.

- Clear test setup and progress displays.

- Easy data export for analysis and reporting.

Versatile Design Options

- Supports various indenter sizes and shapes for different foam materials.

- Accommodates multiple sample sizes, from small cushions to larger foam blocks.

- Optional multi-station setups allow testing several samples at once.

Durability and Noise Reduction

- Heavy-duty frame built to last in busy labs and production lines.

- Noise-reducing design minimizes distractions during testing.

- Low-maintenance parts reduce downtime and service costs.

Benefits Matrix

| Feature | Benefit | Outcome |

|---|---|---|

| Precision Controls | Consistent testing parameters | Accurate, repeatable results |

| User-Friendly PLC | Easy operation | Less training, faster setup |

| Versatile Design | Flexible testing capabilities | Broader material compatibility |

| Durable Build | Long service life | Lower maintenance costs |

| Noise Reduction | Quieter operation | More comfortable work environment |

With its smart design and reliable features, this foam fatigue testing machine helps U.S. manufacturers meet strict quality standards while improving lab efficiency.

Technical Specifications

Our Foam Dynamic Fatigue Tester meets key industry standards to ensure reliable and consistent results:

| Standard Compliance | ISO 3385, ASTM D3574, GB/T 10810 |

|---|---|

| Cycle Rate | 30 to 120 cycles per minute |

| Force Range | 10 N to 500 N |

| Indenter Sizes | Multiple options: 25 mm, 50 mm, 75 mm diameters |

| Sample Sizes | Up to 300 mm × 300 mm |

| Power Supply | 110V/220V, 50/60 Hz |

| Dimensions (L×W×H) | 24″ × 20″ × 40″ (610 mm × 510 mm × 1015 mm) |

| Weight | Approx. 150 lbs (68 kg) |

| Control System | User-friendly PLC with digital touch interface |

Custom Options & Certifications

- Tailored indenter kits for special foam types

- Multi-station configurations for higher throughput

- Optional software modules for enhanced data analysis

- Calibration certificates traceable to national standards

- UL and CE certifications available on request

This setup offers the flexibility and precision U.S. manufacturers need to test PU foam, latex foam, upholstery foam, and other flexible materials with confidence.

Standards Compliance and Test Methods

Our Foam Dynamic Fatigue Tester fully complies with ISO 3385, ensuring precise and reliable fatigue testing of flexible cellular materials like PU foam and latex. The ISO 3385 standard outlines a detailed procedure for repeated cyclic compression, helping you assess foam durability under real-world conditions.

We also cross-reference key standards such as ASTM D3574 and JIS, making sure our equipment meets broad industry requirements. This alignment means you can trust the test results whether you’re following international or U.S. protocols.

Meeting these standards is crucial—not just for quality control but also for OEM specifications and reducing costly product recalls. Accurate, standardized fatigue testing supports consistent product performance and helps you avoid surprises down the road.

Accessories and Options for Foam Dynamic Fatigue Tester

We offer a range of accessories and options to tailor the Foam Dynamic Fatigue Tester to your specific needs:

- Indenter Kits: Various shapes and sizes to match different foam types and test requirements.

- Multi-Station Upgrades: Test multiple foam samples simultaneously to boost lab productivity.

- Software Modules: Enhanced data analysis, reporting features, and remote control capabilities.

- Calibration Tools: Ensure accuracy with easy-to-use calibration kits and traceable certificates.

Pricing Tiers Overview

| Package | Features | Ideal For | Pricing Range |

|---|---|---|---|

| Basic Kit | Standard indenter, single station | Small labs, R&D | $8,000 – $12,000 |

| Professional | Multi-indenter kits, software add-on | Medium volume testing | $12,000 – $18,000 |

| Enterprise | Multi-station system, full calibration suite | High-volume production | $18,000+ |

Need help picking the right combination? Contact us for a custom quote that fits your foam fatigue testing setup.

Installation, Operation, and Maintenance

Setting up your Foam Dynamic Fatigue Tester is straightforward. We provide clear, step-by-step setup and calibration guidance to get you testing quickly and accurately. Our user-friendly PLC interface simplifies operation, so you can control test parameters with ease.

Easy Setup and Calibration

- Follow the quick-start guide for proper installation.

- Calibrate using included tools and software modules.

- Adjust force, cycle rate, and indenter settings to match your material specs.

Maintenance Schedules

- Perform routine inspections monthly to check wear on indenters and moving parts.

- Lubricate mechanical components quarterly to reduce noise and ensure smooth operation.

- Schedule full system calibration annually to keep testing precise and consistent.

Troubleshooting Tips

- If the tester isn’t reaching set force levels, check air pressure and hydraulic connections.

- Persistent noise? Verify lubrication and tighten any loose parts.

- For software glitches, restart the PLC controller and update firmware as needed.

- Contact tech support for any equipment or calibration concerns.

With proper setup and maintenance, your foam fatigue testing machine will deliver reliable, repeatable results while minimizing downtime.

Customer Testimonials and Case Studies

Our Foam Dynamic Fatigue Tester has earned solid praise from industry professionals across the U.S. Here’s what some of our customers have to say:

- “Since switching to this foam fatigue testing machine, we’ve cut product failures by 30%. It’s reliable and easy to operate.” – Quality Control Manager, Upholstery Manufacturer

- “The constant force pounding tester helped us meet stricter OEM specs without adding testing time. A real game-changer.” – R&D Engineer, PU Foam Producer

- “Setup was quick, and the multi-station foam fatigue rig has boosted our lab’s throughput significantly.” – Lab Supervisor, Foam Testing Facility

Case Studies Showing ROI Improvements

- A Midwest foam supplier reported a 25% reduction in warranty claims after adopting our foam pounding fatigue test apparatus, saving thousands annually.

- A California-based furniture maker increased foam durability test accuracy, resulting in 15% fewer product recalls and improved customer satisfaction scores.

- A polymer foam manufacturer saw lab efficiency jump by 40% thanks to our multi-station foam fatigue testing system, reducing labor costs and speeding product launches.

These real-world results reflect how our equipment delivers dependable, precise testing while making your operations leaner and more cost-effective.

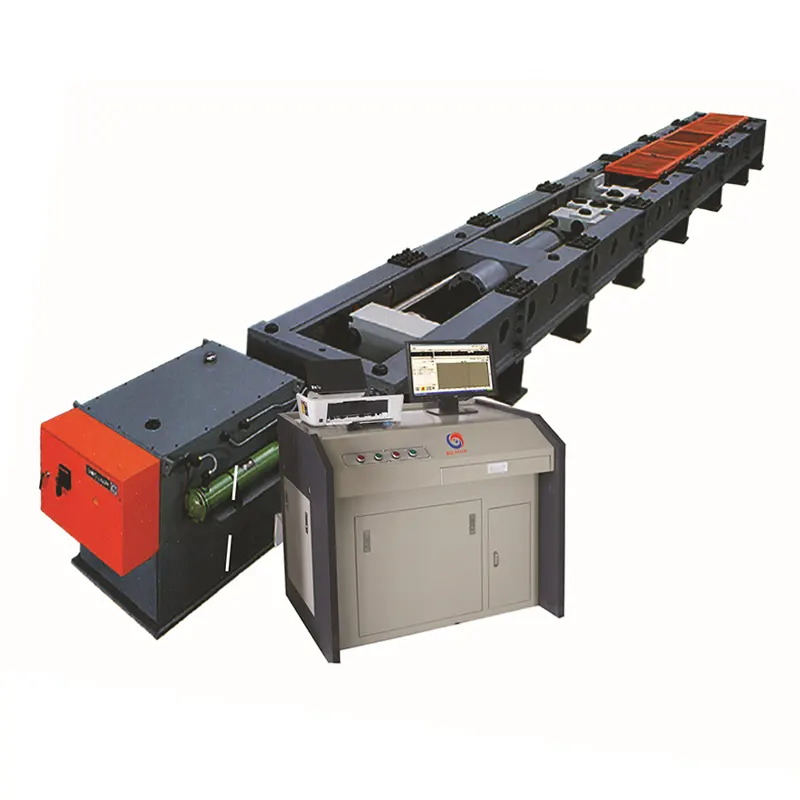

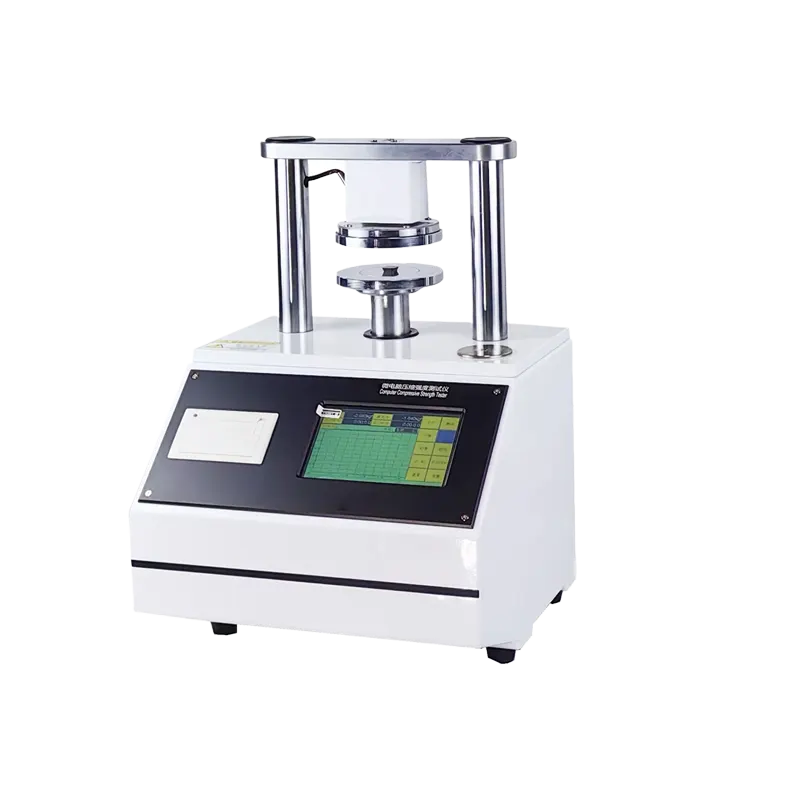

Related Products

Expand your testing capabilities with our complementary equipment designed to cover all your foam analysis needs:

- Indentation Hardness Testers: Accurately measure foam firmness for quality control.

- Resilience Testers: Check how well foam bounces back after compression.

- Foam Air Permeability Testers: Assess breathability and airflow through foam materials.

For labs handling high volumes or multiple samples, we offer our Multi-Station Foam Fatigue Testing Systems. These rigs let you run several tests simultaneously, speeding up your workflow without sacrificing precision.

All our products are crafted with the same commitment to reliability and ease of use as our Foam Dynamic Fatigue Tester, making them a smart addition to your testing lineup.

Ready to See the Foam Dynamic Fatigue Tester in Action?

Download our brochure to get all the specs and details in one place. Want a closer look? Schedule a demo with our team to see how this foam fatigue testing machine can fit your needs. Have questions or want a quote? Contact our sales experts anytime—we’re here to help you find the perfect solution.

Reliable Warranty and Support You Can Count On

We stand behind our Foam Dynamic Fatigue Tester with a solid warranty and dedicated technical support. Whether it’s setup help or ongoing maintenance, our U.S.-based support team is ready to assist, keeping your equipment running smoothly and minimizing downtime.