If you’re serious about ensuring your products can withstand real-world wear and tear, a puncture testing machine is an absolute must-have. Whether you’re in packaging, automotive, textiles, or industrial manufacturing, understanding how materials respond to puncture forces is critical for quality and safety. In this guide, we’ll break down exactly what a puncture testing machine is, how it works, and how to choose the right one for your needs—plus why trusted brands like Derui are setting the standard in precision testing. Ready to get the full picture and make informed decisions? Let’s dive in.

What is a Puncture Testing Machine

A puncture testing machine is a device designed to measure the resistance of materials to puncture or penetration. This type of testing is crucial for understanding how sturdy or vulnerable a material is when subjected to sharp or pointed forces. Puncture resistance testing helps manufacturers ensure product durability, safety, and quality across various industries.

Definition of Puncture Resistance Testing

Puncture resistance testing evaluates how much force a material can withstand before being pierced or punctured. It’s commonly used for films, packaging, textiles, medical devices, and industrial materials. The test simulates real-world conditions where materials face stress from sharp objects, helping to predict performance and failure points.

Key Components of Puncture Testing Machines

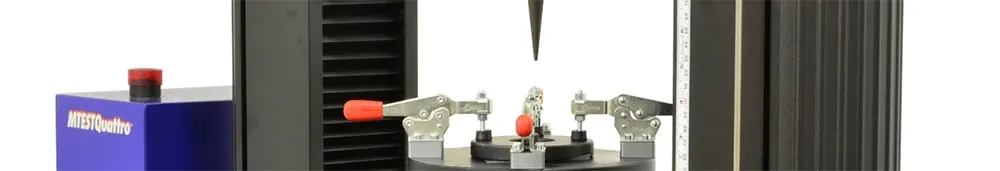

Most puncture testing machines include:

- Load frame: Holds the sample in place during the test.

- Probe or puncture tip: The shaped element that applies force to the material.

- Force sensor/load cell: Measures the resistance force accurately.

- Control system: Regulates the test speed and records data.

- Fixture or clamps: Secure the material sample.

Types of Puncture Testing Machines

There are several types based on application and test requirements:

- Manual puncture testers: Basic models for simpler, routine tests.

- Digital puncture testing devices: Offer precise control and data recording.

- Automated puncture testing systems: Ideal for high-volume testing with minimal operator input.

- Specialized testers: Designed for specific materials like rubber, plastic, or medical packaging.

How Puncture Testing Works

During testing, a probe pushes against the material at a controlled speed until it punctures the sample. The machine measures the force applied and the point of failure. This data helps assess the material’s puncture strength and durability.

Test Methods and Standards

Puncture testing follows industry standards to ensure consistency and reliability, including:

- ASTM F1306: Standard test method for puncture resistance of packaging materials.

- ISTA test standards: Guidelines for package integrity verification.

- Other regional or industry-specific protocols based on material type.

Using these methods, the test environment, force application speed, and probe shape are standardized, allowing for comparable results across different tests and machines.

Key Features of Puncture Testing Machines

Puncture testing machines are built tough to handle a range of materials—from thin films and packaging to thick rubber and composites. Here’s what you can expect in a good machine:

Machine Construction and Materials Tested

- Sturdy Frame: Usually made from steel or aluminum for durability and stability.

- Material Compatibility: Tests plastics, rubber, textiles, composites, metals, and packaging films.

- Versatile Test Heads: Different puncture probes and tips to match the material type.

Load Capacity and Measurement Accuracy

- Load Range: From a few newtons for delicate films up to thousands of newtons for industrial materials.

- Precision Sensors: High-accuracy load cells ensure reliable puncture force readings.

- Consistent Results: Repeatability is key for quality control and R&D.

Digital Control Systems and Data Output

- User-Friendly Touchscreens: Easy to set test parameters and control machine functions.

- Data Logging: Records force, time, and displacement for detailed analysis.

- Connectivity: USB, Ethernet, or wireless for exporting test data into quality systems.

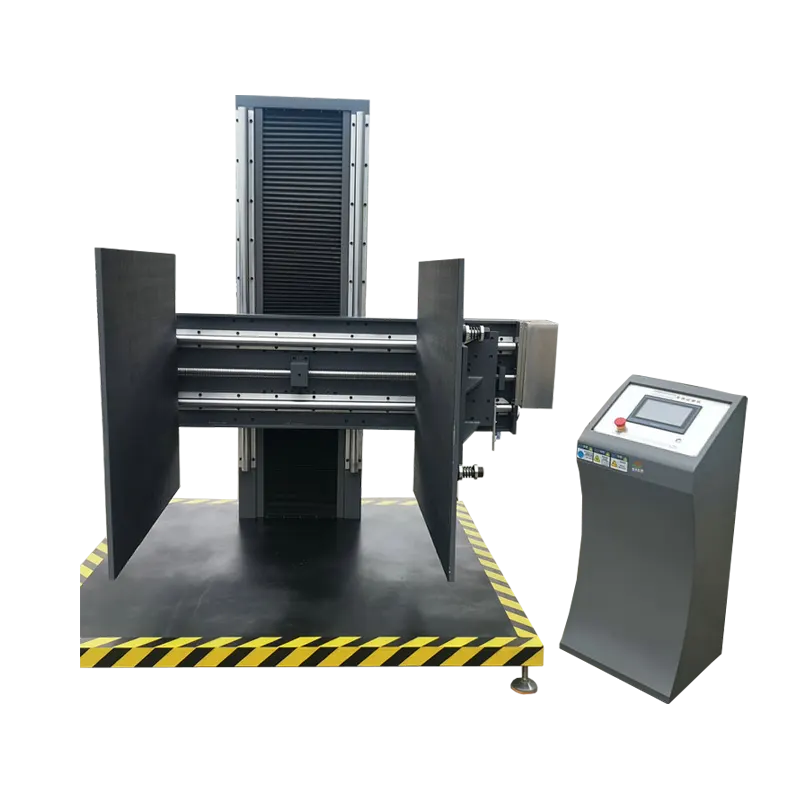

Safety Features and Compliance

- Safety Shields and Emergency Stops: Protect operators during testing.

- Standards Compliance: Meets ASTM, ISO, ISTA, and other puncture testing standards.

- Automatic Shutoff: Prevents damage in overforce situations.

User Interface and Automation Trends

- Intuitive Controls: Step-by-step guidance reduces training time.

- Automation Options: Programmable sequences and automated sample handling improve throughput.

- Remote Monitoring: Some models support control and data review via mobile devices.

| Feature | Details |

|---|---|

| Construction | Steel/aluminum frame for stability |

| Materials Tested | Plastics, rubber, textiles, composites, metals |

| Load Capacity | From low force to 10,000+ N |

| Measurement Accuracy | High-precision load cells with repeatability |

| Control System | Digital touchscreen with data export options |

| Safety | Shields, emergency stops, standards compliance |

| Automation | Programmable tests with remote monitoring |

These features ensure that puncture resistance testing machines deliver dependable, accurate, and safe performance for a wide variety of industries across the U.S. market.

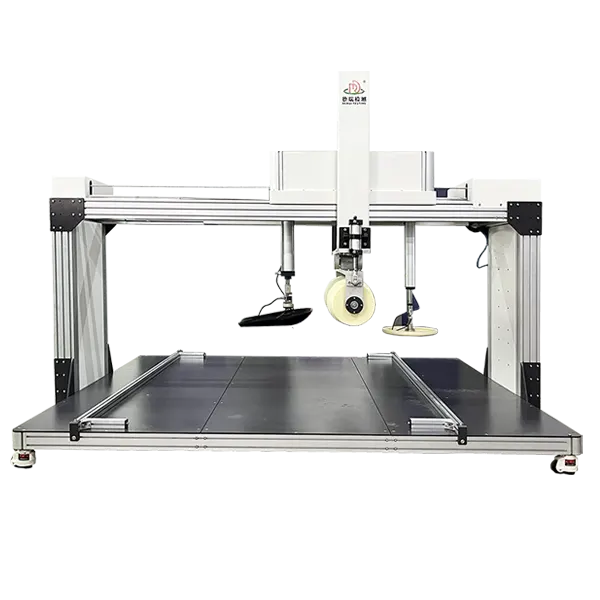

Applications of Puncture Testing Machines

Puncture testing machines are essential across many industries to ensure material strength and durability. In the packaging industry, they test films, bags, and containers for puncture resistance, helping verify package integrity and meet ASTM F1306 and ISTA test standards.

In automotive and aerospace sectors, these machines check composites, cushions, and safety materials to ensure they can withstand impact and stress, improving product safety and performance.

For the textile and apparel industry, puncture testers evaluate fabrics and protective gear, such as gloves and workwear, to guarantee they provide adequate durability and protection against penetration.

Within medical device testing, puncture resistance is critical for gloves, membranes, and packaging, ensuring patient safety and compliance with strict regulatory requirements.

Finally, puncture testing machines assess industrial materials like rubber, plastics, and metals to measure their puncture durability, supporting quality control in manufacturing and material development.

Benefits of Conducting Puncture Testing

Puncture testing helps make sure products meet high standards for quality and durability. By testing materials for puncture resistance, manufacturers can spot weak points before products hit the market, preventing failures in real-world use.

Key Benefits

| Benefit | Explanation |

|---|---|

| Product Quality and Durability | Confirms materials withstand everyday wear and tear. |

| Regulatory Compliance | Meets safety standards like ASTM F1306 and ISTA, avoiding legal issues. |

| Cost Savings | Detects weaknesses early, cutting down on costly recalls and repairs. |

| Drives Innovation | Data from tests helps improve materials and designs. |

| Customer Satisfaction | Reliable products build trust and reduce returns. |

How to Choose the Right Puncture Testing Machine

Picking the right puncture testing machine starts with knowing your specific needs. Here’s what to consider:

Assess Your Test Requirements

- Materials: What will you test? Films, plastics, rubber, textiles, or metals? Each needs different puncture force ranges.

- Puncture forces: Estimate the force range—light films need low force, industrial materials much higher.

- Environment: Will testing be done in a lab, production line, or outdoors? This affects durability and machine features.

Key Machine Specifications

| Specification | What to Look For |

|---|---|

| Load Range | Matches expected puncture forces |

| Size | Fits your workspace and sample dimensions |

| Customization | Option for specific test methods or sample holders |

Brand and Support

- Choose brands with reliable after-sales service and local technical support.

- Check reviews or case studies to ensure product reliability.

Budgeting Tips

- Balance price with performance and accuracy.

- Avoid low-cost models that compromise measurement precision.

- Consider machines with digital systems and automation if you need data integration.

Integration with Quality Control

- Look for machines that can connect with your existing QC system or software.

- Automated data recording helps maintain consistent product standards and speeds up reporting.

By focusing on these points, you can find a puncture resistance testing machine that fits your US market needs, testing goals, and budget.

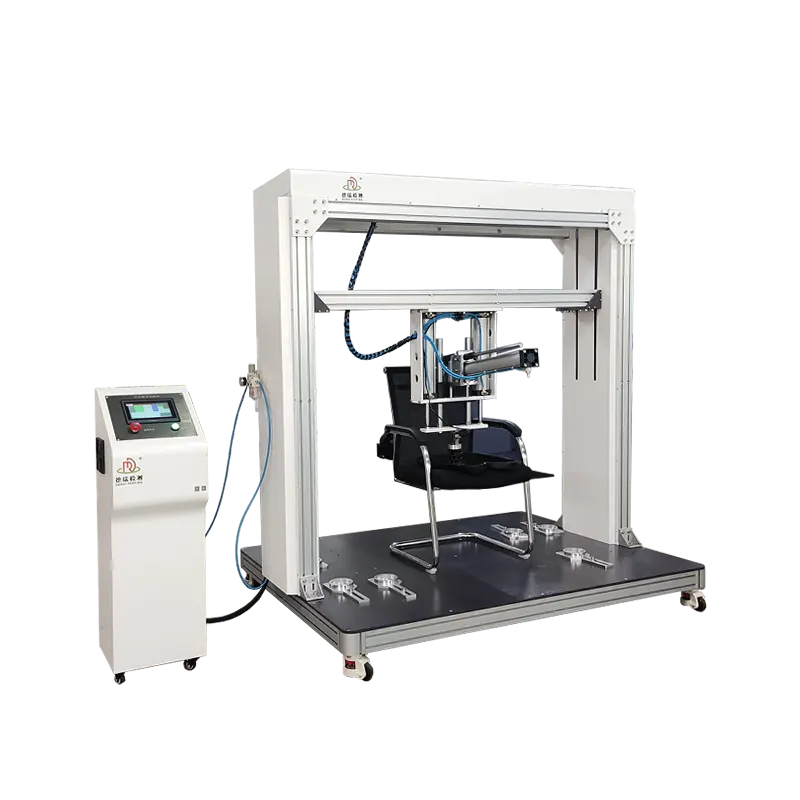

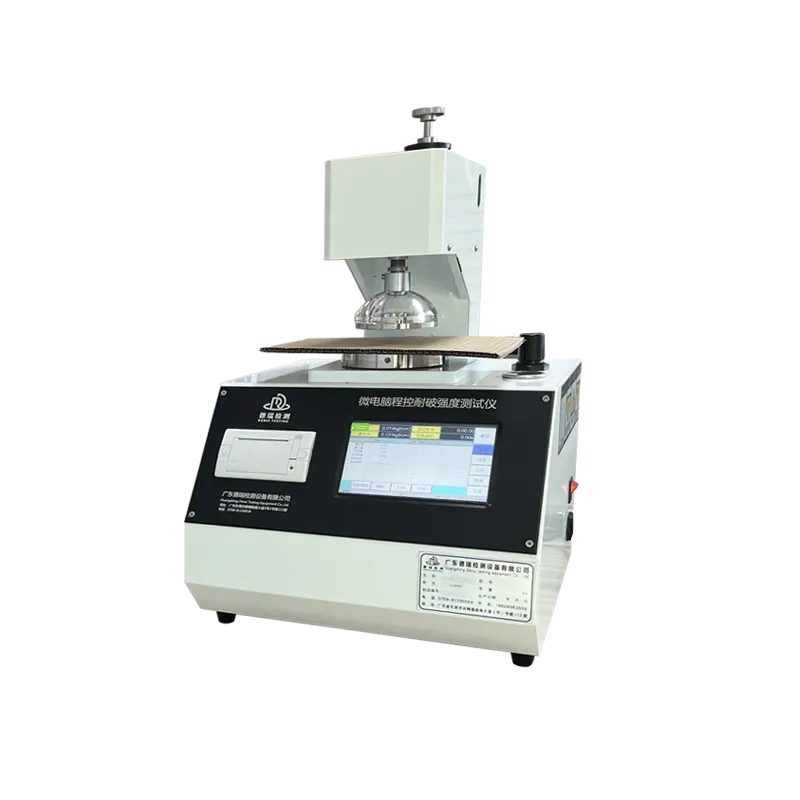

Why Choose Derui Puncture Testing Machines

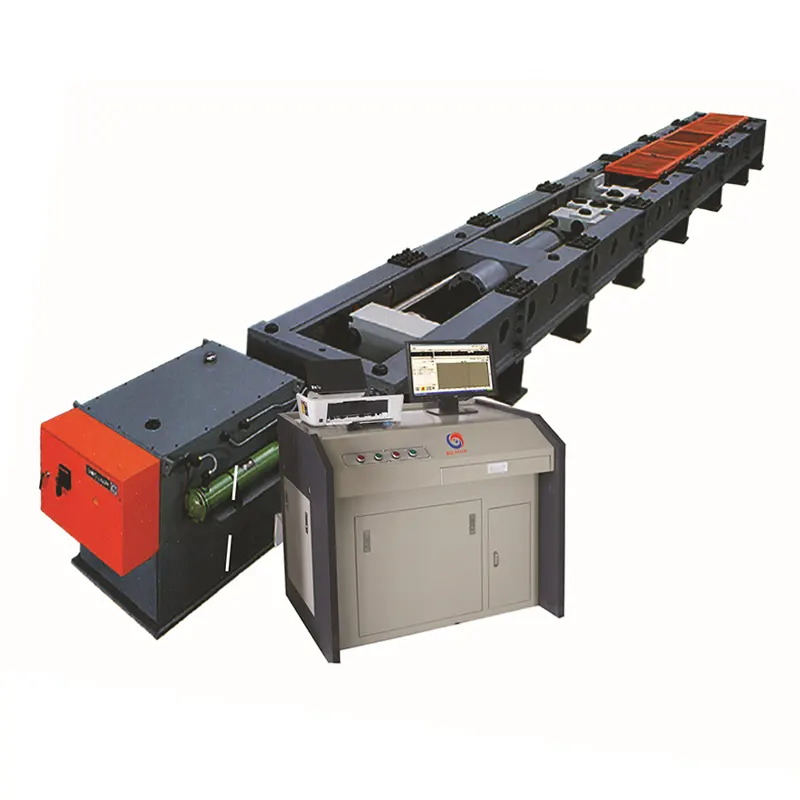

Derui stands out in the US market thanks to years of expertise designing reliable puncture resistance testing equipment. Their product range covers everything from compact digital puncture testing devices to heavy-duty industrial puncture test machines — perfect for a variety of materials like films, plastics, rubber, textiles, and composites.

What Makes Derui Unique

| Feature | Benefit |

|---|---|

| High Precision | Accurate load capacity measurement for consistent test results |

| Durable Build | Long-lasting machines built with quality materials |

| User-Friendly Interface | Easy controls and seamless digital data output simplify testing |

| Customization Options | Machines adapted to fit specific industry needs and test methods |

Derui machines also come with automation capabilities, boosting efficiency in busy lab environments or production lines.

Customer Feedback and Support

Many US businesses report improved quality control after switching to Derui puncture testers. Case studies highlight increased test accuracy and reduced downtime. Derui backs their products with solid warranty coverage plus training services, ensuring operators get up to speed and machines stay calibrated.

Choosing Derui means investing in dependable puncture durability testing equipment that aligns with ASTM and ISTA standards widely used across medical packaging, automotive, and industrial sectors in the United States.

Maintenance and Calibration Tips for Puncture Testing Machines

Keeping your puncture testing machine in top shape is essential for accurate, reliable results. Here’s how to maintain and calibrate your equipment efficiently:

Routine Machine Care

- Clean regularly: Wipe down surfaces and remove debris to prevent buildup that can affect sensor accuracy.

- Inspect components: Check needles, grips, and clamps for wear or damage before each test.

- Lubricate moving parts: Use recommended lubricants to keep mechanical parts running smoothly.

- Check connections: Ensure cables and sensors are secure and free of corrosion.

Calibration Practices and Frequency

- Calibrate regularly: Follow the machine’s manual but typically calibrate every 3-6 months or after heavy use.

- Use certified weights: Calibrate load cells and sensors with certified calibration weights or tools.

- Document calibrations: Keep records of dates, procedures, and results for quality control and audits.

- Recalibrate after repairs: Any part replacement or repair should be followed by a full calibration check.

Troubleshooting Common Issues

- Inconsistent load readings: Check for sensor damage or loose connections; recalibrate if needed.

- Machine not starting: Inspect power supply and emergency stops; verify software settings.

- Unresponsive controls: Restart system and update software; check for hardware faults.

- Irregular test results: Confirm sample setup and test method; retest and review machine calibration.

Proper maintenance and timely calibration keep your puncture resistance testing equipment accurate and extend its lifespan, ensuring you get dependable data every time.

Frequently Asked Questions FAQs

What materials can be tested with a puncture testing machine?

You can test a wide range of materials, including packaging films, plastic bags, rubber sheets, textiles, composites, medical gloves, and even some thin metals. These machines are versatile enough to handle anything where puncture resistance matters.

How long does a puncture test usually take?

Most puncture tests are quick, typically lasting anywhere from a few seconds to a couple of minutes. The exact time depends on the material and the test method being used, but modern digital puncture testing devices speed up the process significantly.

Are there international standards relevant to puncture testing?

Yes, several standards guide puncture resistance testing. Common ones include ASTM F1306 for packaging films, ISTA test standards for package integrity, and other industry-specific regulations. These standards help ensure consistent, reliable results.

Can puncture testing machines be customized for specific industries?

Absolutely. Many puncture resistance testing equipment manufacturers offer customization options. This includes adjusting load capacity, test speed, probe types, and software settings to fit unique materials or industry requirements such as automotive composites, medical membranes, or industrial plastics.