What is a Small Tensile Testing Machine

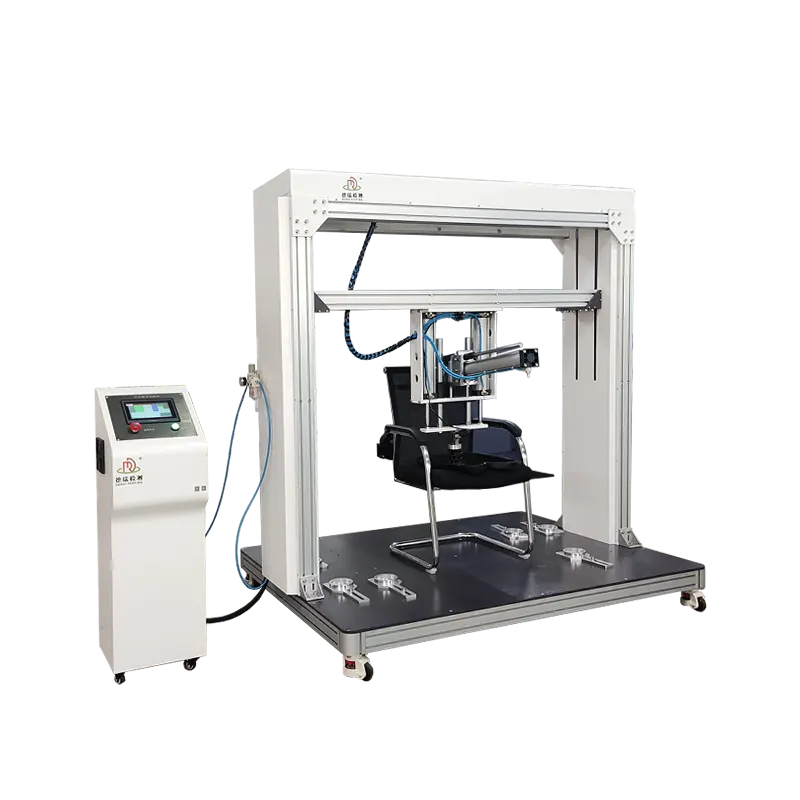

A small tensile testing machine is a compact device designed to measure the tensile strength, elongation, and other mechanical properties of materials. Tensile testing machines work by applying a controlled pulling force to a material sample until it breaks or deforms, assessing how the sample responds under stress.

What sets small tensile testing machines apart from standard models are their size and capacity. These machines typically feature lower maximum load capacities, often ranging from a few hundred newtons to several thousand newtons, making them ideal for testing smaller or more delicate samples. Their compact footprint allows them to fit comfortably in limited spaces such as small labs, offices, or educational settings.

Small tensile testers come in several common types and configurations:

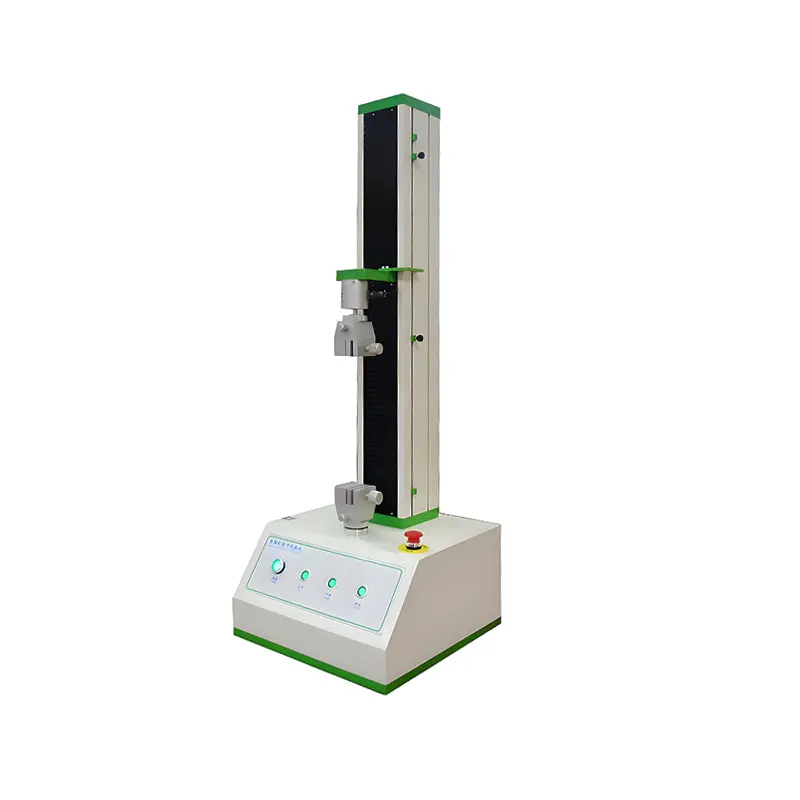

- Electromechanical models: Use electric motors and screws to apply force with precise control; known for smooth operation and accuracy.

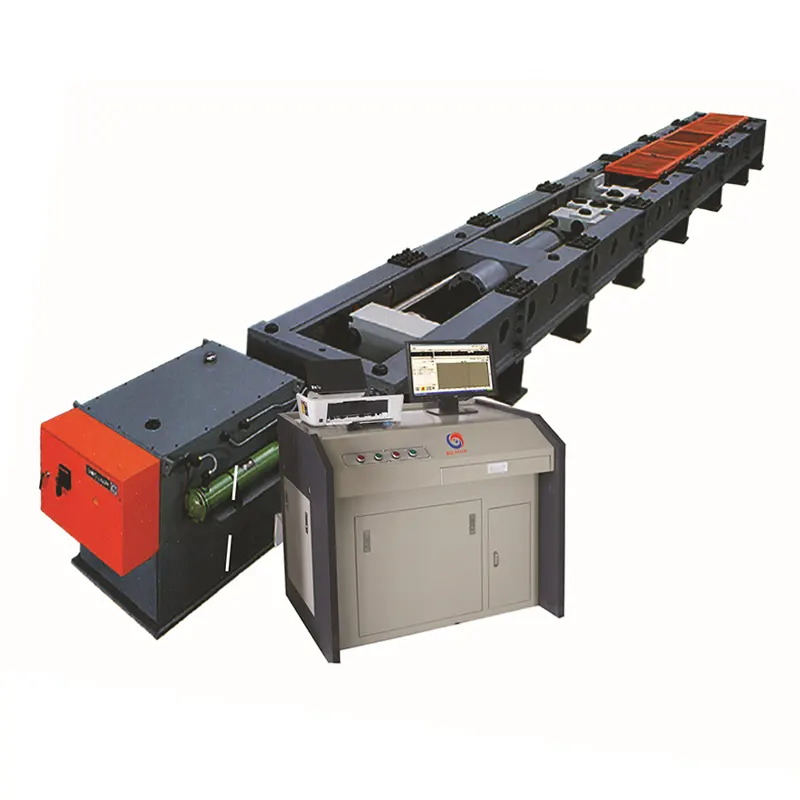

- Hydraulic models: Employ hydraulic pressure for higher force capacities but are usually bulkier.

- Desktop models: Specifically designed for benchtop use, combining portability with essential testing functions.

These variations cater to different testing needs while maintaining small-scale operation without sacrificing reliability.

Key Applications and Industries Using Small Tensile Testing Machines

Small tensile testing machines are widely used across various industries because they offer precise material analysis in a compact form. Here’s where they make the most impact:

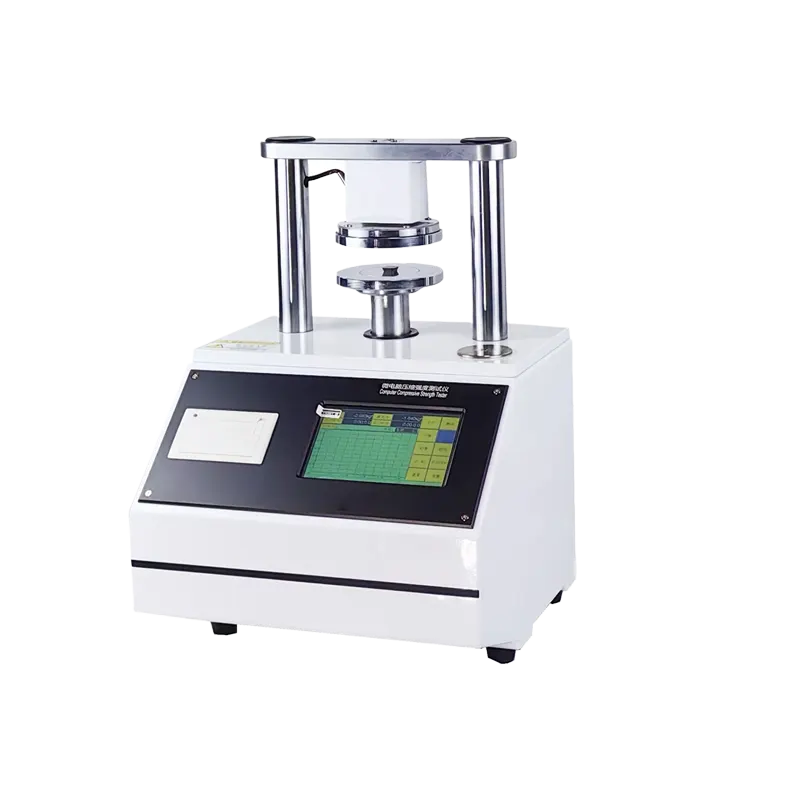

- Materials TestingThese machines test tensile strength in metals, plastics, textiles, and composites. Whether you’re checking raw material quality or verifying finished product durability, small-scale force testing machines provide reliable data.

- Quality Control in ManufacturingManufacturers rely on these devices to ensure products meet standards before shipping. From automotive parts to packaging materials, desktop tensile testing machines help catch defects early.

- Education and ResearchLabs in universities and technical schools use compact tensile strength testers for hands-on learning. Their ease of use and affordable price make them perfect for teaching material properties and testing methods.

- R&D Laboratories and StartupsSmall businesses and research setups often don’t have room for big equipment. Portable tensile testing devices fit tight spaces and support innovation without sacrificing accuracy or functionality.

These applications highlight the adaptability of small tensile testing machines in testing materials and supporting a variety of industries well suited to the U.S. market.

Advantages of Small Tensile Testing Machines over Traditional Models

Small tensile testing machines offer a space-saving design that fits perfectly in tight labs or office spaces. Unlike bulky universal tensile testing machines, these compact models free up valuable workspace without sacrificing performance.

Cost-wise, they are a smart investment. You get accurate tensile strength testing without the high price tag of larger, more complex systems. This makes them ideal for startups, small R&D labs, and quality control departments on a budget.

Portability is another big plus. Lightweight and often designed as desktop or portable tensile testing devices, small machines can easily move between testing stations or worksites. This flexibility helps integrate testing into various environments without hassle.

Plus, these small-scale force testing machines usually come with user-friendly software. The interfaces simplify data acquisition, analysis, and reporting, so operators spend less time navigating complicated systems and more time focusing on their materials testing.

Essential Features to Look For in a Small Tensile Testing Machine

When choosing a small tensile testing machine, it’s important to focus on features that match your testing needs without overpaying for extras. Here’s what to keep an eye on:

| Feature | What to Look For |

|---|---|

| Load capacity | Matches the materials you test (usually up to a few kN for small testers) |

| Measurement range | Wide enough to cover both low and high forces accurately |

| Precision and accuracy | Compliance with ISO and ASTM standards ensures reliable results |

| Testing speed | Adjustable speeds to fit different sample types and test requirements |

| Sample gripping | Versatile grips that handle various shapes like flat, round, or irregular |

| Software capabilities | User-friendly software with data acquisition, reporting, and remote control features |

| Safety features | Emergency stop, overload protection, and easy-to-maintain design |

| Maintenance | Simple calibration procedures and accessible parts for quick upkeep |

Making sure your small tensile strength tester has these essentials will help you get dependable results and make daily operations smoother.

How to Choose the Right Small Tensile Testing Machine for Your Needs

Picking the right small tensile testing machine starts with understanding what you need. Here’s a quick guide to help you decide:

Assess Your Testing Requirements and Material Types

- What materials will you test? Metals, plastics, textiles, or composites?

- What’s the typical sample size and shape?

- Do you need specific test types like tensile, compression, or flexural?

Budget Considerations and Return on Investment

- Determine how much you can spend upfront.

- Factor in long-term savings from durable, low-maintenance machines.

- Consider if the machine increases lab productivity or quality control — that’s ROI too.

Space Constraints and Bench Footprint

- Measure your available lab or office space.

- Small tensile testers vary in weight and size—choose one that fits without crowding your work area.

| Factor | Considerations |

|---|---|

| Footprint | Compact design for tight labs |

| Weight | Lightweight for portability |

| Installation | Easy setup without special tools |

Support and Warranty from the Manufacturer

- Look for a trusted brand with strong customer service.

- Check warranty length and what it covers.

- Easy access to parts and technical support matters for uptime.

Derui’s Models Designed for Compact Spaces

- Derui offers desktop tensile testing machines ideal for small labs in the US.

- Their compact tensile strength testers combine accuracy with space-saving design.

- Models come with user-friendly software and reliable support tailored to local needs.

Installation Operation and Maintenance Tips

Setting up your small tensile testing machine right is key to getting accurate, consistent results. Start by placing the machine on a stable, level surface away from direct sunlight, dust, and vibrations. Make sure it’s close to a power source and has enough space around it for easy access during testing.

When preparing samples, keep these best practices in mind:

- Use smooth, clean samples free of defects

- Follow standard preparation methods for your material type (metal, polymer, textile)

- Secure samples properly with the right grips to avoid slipping or damage

- Keep the sample aligned straight to ensure precise force application

For routine maintenance:

- Clean the machine regularly, especially grips and moving parts

- Lubricate mechanical sections as recommended in the user manual

- Check electrical connections and cables for wear

- Calibrate your machine periodically using certified weights or reference standards to meet ISO or ASTM accuracy requirements

If you run into common issues:

- A slipping sample usually means grip tension needs adjustment or you need different grips

- Inconsistent readings can be a sign of poor calibration or sample misalignment

- Software glitches often resolve with a system reboot or updating the software

- For unusual noises or mechanical problems, stop testing and contact support immediately to avoid damage

Following these setup, operation, and maintenance tips helps you maximize the lifespan and accuracy of your small tensile testing machine, keeping your workflow smooth and reliable.

Case Study How Derui’s Small Tensile Testing Machine Helped a Local Lab Improve Testing Accuracy and Efficiency

A local materials testing lab in the Midwest was struggling with limited space and outdated equipment that couldn’t deliver consistent results. They needed a reliable, compact tensile testing machine that could handle a variety of materials—metals, plastics, and composites—without taking up too much room or adding complexity to their workflow.

Derui’s small tensile testing machine was an ideal fit. The lab installed one of Derui’s desktop tensile testing machines designed specifically for tight spaces and versatile testing needs. The setup was straightforward, and the user-friendly software helped the staff quickly adapt to its functions without extensive training.

After switching to Derui’s compact tester, the lab saw notable improvements:

- Increased precision: Test results were more consistent and met ISO and ASTM standards, helping the lab pass audits and satisfy customers.

- Space savings: The smaller footprint freed up valuable bench space, allowing the lab to reorganize and include other instruments.

- Cost efficiency: Compared to previous models, the investment was lower while maintaining high accuracy, improving overall budget management.

- Faster testing: The intuitive interface and software features sped up data collection and reporting, boosting daily productivity.

Overall, Derui’s small tensile testing machine helped the lab enhance both their accuracy and efficiency while dealing with real-world space and budget limitations common in many U.S. testing facilities.

Frequently Asked Questions about Small Tensile Testing Machines

Can small tensile testers handle large samples

Small tensile testing machines are designed for smaller or medium-sized samples. While they work great for most lab-scale materials, very large or bulky samples may exceed their capacity. It’s best to check the load capacity and sample size limits before purchasing to ensure it fits your testing needs.

What materials can be tested with a small tensile testing machine

These machines are versatile. You can test metals, plastics, textiles, composites, and polymers. Because of their design, they work well for common lab materials and smaller production samples, making them suitable for quality control and research.

How to interpret tensile test results

Tensile test results typically show stress, strain, and breaking points of a material. The machine’s software usually provides graphs and data that help you understand strength, elasticity, and failure points. Look at maximum load, elongation at break, and Young’s modulus to evaluate material performance.

How portable are these machines

Most small tensile testing machines are lightweight and compact enough to move between labs or testing areas easily. Desktop or portable tensile testing devices can also fit on bench tops, making them ideal for on-site testing or small workspaces.

Warranty and support specifics from Derui

Derui offers solid warranty plans and customer support tailored to U.S. customers. They provide installation assistance, remote software updates, and responsive technical support to keep your machine running smoothly. Warranty details vary by model, but typically cover defects and offer service options to protect your investment.