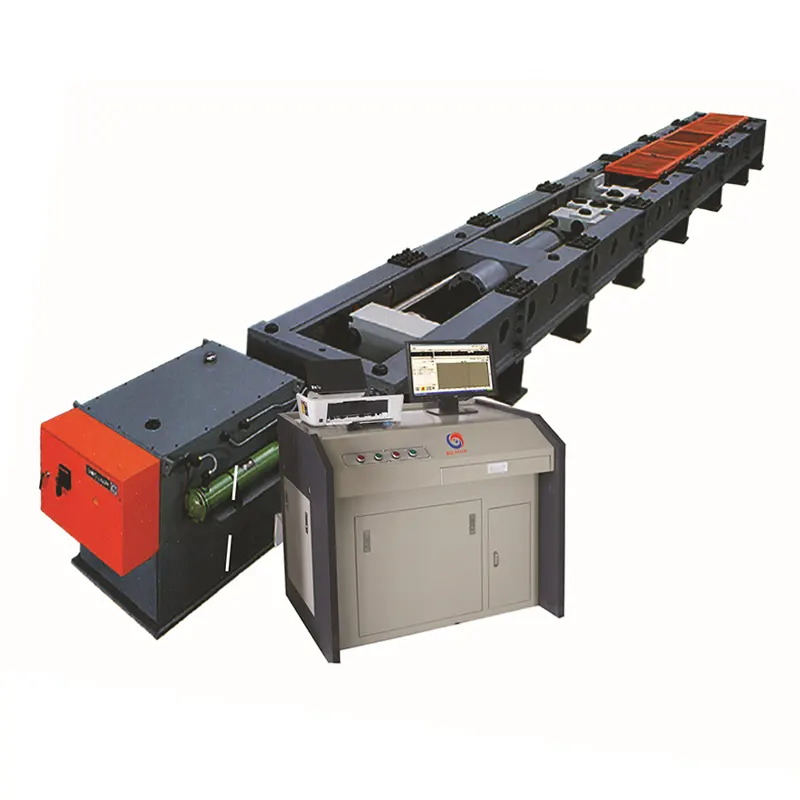

The microcomputer compression strength tester (also known as ring crush tester, compression tester, edge crush tester) is a new type of high-precision detection instrument developed by our company in accordance with national standards. It is mainly suitable for testing the ring crush strength (RCT) of paper with a thickness of 0.15 to 1.00mm; edge crush strength (ECT), flat crush strength (FCT), adhesive strength (PAT) of corrugated board, and flat crush strength (CMT) of paper cores with a diameter less than 60mm. It is currently one of the most cost-effective high-precision compression strength testing instruments in China.

This instrument features an integrated mechanical and electrical structure, and is meticulously designed with modern mechanical design concepts and microcomputer processing technology. It adopts a fixed upper pressure plate, ensuring high measurement accuracy. The instrument is equipped with various functions such as testing, conversion, adjustment, memory, real-time display of pressure curves, and data printing as specified in the standards. It has a powerful data processing function, capable of directly providing statistical results of all data, and can automatically reset. It is easy to operate and adjust, with stable performance.

Ring Crush Test (RCT)

Chinese standards:

GB/T 2679.8 "Method for Determining the Ring Crush Resistance of Paperboard"

GB/T 22874 "Determination of Flat Crush Strength of Single-faced and Single-walled Corrugated Board"

International standards:

ISO 12192 "Compressive strength test of paper and board"

TAPPI T822 (Technical Association of the Pulp and Paper Industry Standard)

Edge Crush Test (ECT)

GB/T 6546 "Method for Determining Edge Crush Test (ECT) of Corrugated Board"

ISO 3037 (Equivalent Chinese National Standard)

Peel Adhesion Strength (PAT)

GB/T 6548 "Method for Determining the Bonding Strength of Corrugated Board"

TAPPI T821 (Adhesive Peel Strength Test)

Flat compression strength (FCT)

GB/T 2679.6 "Method for Determining the Flat Crush Strength of Corrugated Core"

ISO 7263 (Test for flat crush strength of corrugated core paper)

Product Features

- Fully computer-controlled technology, open structure, high degree of automation, simple and convenient operation, reliable.

- Fully automatic measurement, intelligent judgment function, large screen LCD display, Chinese menu. During the test, the stretching time, load tension, etc. are displayed in real time.

- Chinese graphic menu display operation interface, simple and convenient to use; the latest QD-3013 software has the function of real-time display of compression curves; the instrument has strong data display and analysis management capabilities.

- Adopting modular integrated printer, easy installation, low failure rate; thermal printer and dot matrix printer are available.

- Automatically measure, statistically analyze and print test results, and has data saving function.

- High-speed micro printer, high printing speed, convenient to use, low failure rate.

- Modern design concept of mechanical and electrical integration, compact structure, elegant appearance, convenient maintenance.

Sample rack accessories:

Ring Crush Center Disk RCT (Ring Crush Test) - Ring Crush Test

● Paper or cardboard samples are placed in a ring shape and subjected to gradually increasing edge compression force until they collapse. The maximum resistance is measured. The RCT value is expressed as force divided by the sample length.

● The standard ring crush center disk can measure paper with a thickness of 0.1 mm to 0.9 mm. There are a total of 13 sub-disks and 1 main disk.

Edge crush test block, ECT (Edge Crush Test) - Edge Crush Test

● The force applied to the corrugated cardboard sample is parallel to the groove until it breaks. The ECT value is expressed as the crushing force divided by the width of the sample.

Bonding fixture, PAT (Pin Adhesion Test) - Bonding test

● Adhesion is the maximum force required to separate the face paper from the core paper with the help of a special sample frame.

Standard configuration: 1 A flute, 1 B flute, 2 C flutes. Other specifications and E flute can be customized.

Flat Crush Tester (FCT) - Flat Crush Test

● Apply an increasing force perpendicular to the surface of the corrugated board sample until the flutes are crushed. The FCT value is expressed as the force divided by the sample's surface area.

● The flat crush tester has two sampling sizes, namely 32.2 cm² (5 in²) and 64.5 cm² (10 in²).

CMT flutes and combs:CMT (Corrugating Medium Test) - corrugated medium flat crush test

● The sample is corrugated between heated corrugating rolls. The flutes are fixed and held together by pressure-sensitive adhesive tape, thereby imitating single-faced corrugated board. A compressive force is applied perpendicular to the plane of the paper, and then the breaking force is measured. The CMT value is the maximum force that the sample can withstand before breaking.

● The instrument comes with the flutes and combs needed to make CMT samples.

CCT sample holder: CCT (Corrugated Crush Test) - Crush test of corrugated core paper

● The sample is corrugated between heated corrugating rolls. The sample is fixed in a special fixture suitable for the corrugated shape. The crushing force is applied and measured parallel to the top of the corrugated core material. The CCT value is the maximum force that the sample can withstand before breaking.

● This CCT sample holder is an optional accessory.