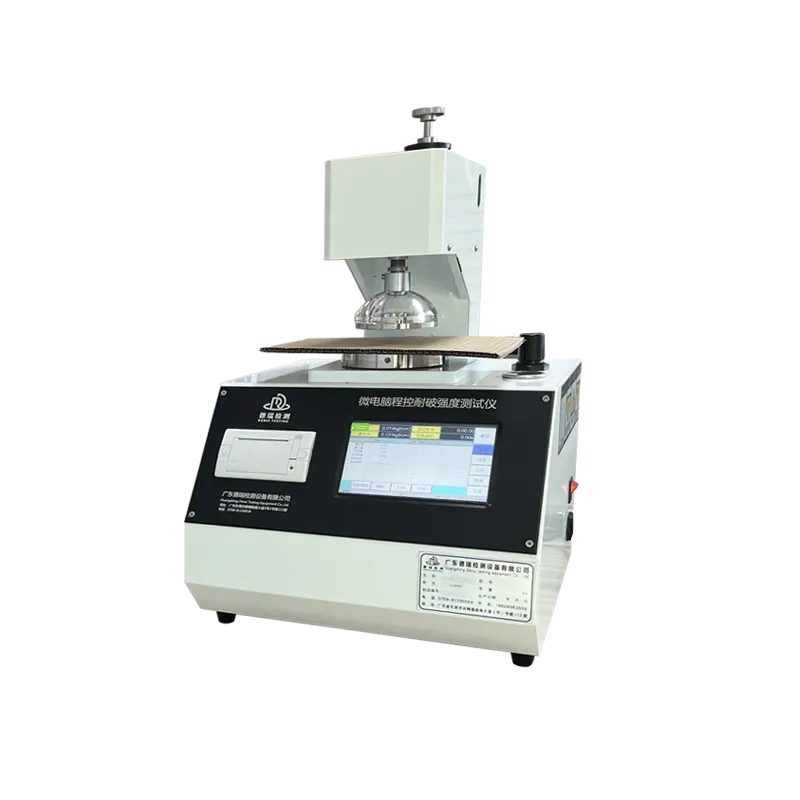

The Foam Drop Ball Rebound Tester is mainly used to measure the resilience performance of polyurethane elastic materials, foams, plastics, sponges and other materials. This instrument uses a standard mass steel ball to freely fall from a certain height and strike the foam sample. After the steel ball strikes the foam, part of the energy will be absorbed by the foam, and the remaining energy will cause the steel ball to rebound. The instrument accurately measures the rebound height or speed of the steel ball to calculate the resilience performance of the foam.

Product Features:

- It can be used to produce both national standard 460 samples and American standard 500 samples.

- Equipped with a liquid crystal display and Chinese interface, it not only extends the service life but also is easy to understand, allowing technicians to quickly master the operation method.

- It comes with a printing function, featuring an integrated mini printer.

Test procedure

Place the adjusted specimen horizontally at the test position of the rebound hammer. Adjust the position so that the drop height from the fixed position of the steel ball to the surface of the foam plastic is 460mm. Fix the steel ball on the release device and then let it fall freely. Perform three rebounds for each specimen and take the average of the three rebound values. Each rebound should land on the same position on the specimen surface, and the time interval between two rebounds should be controlled within 20 seconds. If the steel ball touches or bounces out of the measuring device during the rebound process, the obtained data is invalid and needs to be redone.

Usage Method:

Installation Preparation: Before using the sponge rebound tester, it is necessary to prepare the test samples first and cut them into square or circular shapes, with sizes that should be compatible with the specifications of the testing device.

Instrument adjustment: When using the instrument for the first time, it is necessary to adjust the feet of the base to center the bubble in the right-angle square leveler within the circle, ensuring that the base is in a horizontal position.

Sample placement: Place the test sample at the central position of the test device.

Parameter settings: According to the test requirements, set parameters such as the number of tests and test speed.

Start the test: Press the start button and the instrument will automatically conduct the test. During the test, you can observe the rebound condition of the test sample through the observation window.

Data Recording: After the test is completed, the instrument will automatically record the test data. The test data can be printed or saved.

Cleaning and maintenance: After the test is completed, the testing device and samples need to be cleaned to keep the instrument clean and tidy.

Configuration: