Derui Foam Density Meter: Precision Testing for Superior Foam Quality

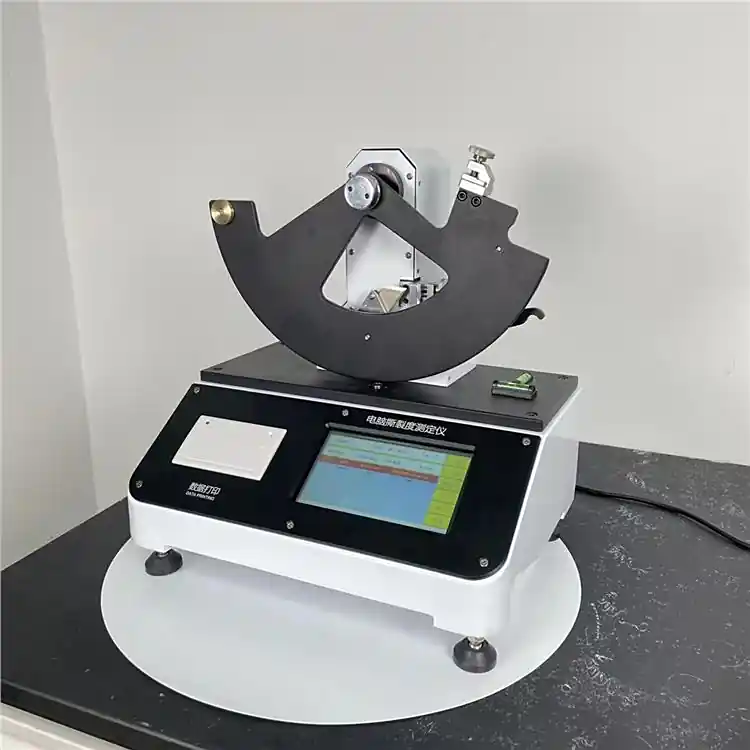

Unlock fast, accurate foam density measurements with the Derui Foam Density Meter—your go-to electronic digital analyzer engineered for precision. Designed to meet ASTM D3574 standards, this advanced foam density tester delivers reliable results for polyurethane, sponge, and packing foams within seconds. Whether you’re ensuring product consistency or performing quality control, count on Derui for seamless testing that saves time without compromising accuracy.

See it in action:Instant density readouts

Easy-to-use digital LCD display

Durable, compact design perfect for any testing environmentGet started today:

Experience foam testing that’s precise, quick, and effortless. Explore our product demo or request a free consultation now!

Product Overview

The Derui Foam Density Meter is a reliable hydrostatic tester designed to quickly and accurately measure foam density, ensuring you get consistent, high-quality results every time. Foam density inconsistencies can lead to poor product performance—whether it’s in furniture cushions, automotive padding, or protective packaging. That’s where the Derui Foam Density Meter comes in, helping you spot and fix these issues fast.

With its electronic digital foam density meter technology, it delivers precise readings in seconds, so you don’t waste time on slow or complicated testing methods. It’s easy to use, even if you’re new to foam density testing, thanks to its clear digital LCD and auto-calibration features. Plus, this foam density tester is built tough to handle the daily demands of your workshop or lab, so you can count on durability for the long haul.

Whether you’re working with polyurethane foam, sponge, or packing foam, the Derui Foam Density Meter provides consistent, ASTM D3574-compliant results—helping you maintain top product quality without the hassle.

Key Features and Benefits of the Foam Density Meter

Our Derui Foam Density Meter comes loaded with features that make foam testing faster, easier, and more reliable for you.

Precise and Reliable Measurement

- High-precision weighing range: Accurate density readings ensure consistency in your foam products.

- Anti-float technology: Keeps samples stable during hydrostatic weighing to prevent errors.

Easy-to-Read Multi-Parameter Display

- Shows multiple measurements at once—no need for manual calculations or conversions.

- Measures density, water absorption, closed pore volume, and expansion rate quickly.

Meets Industry Standards

- Complies with ASTM D3574, ISO 1817, and JIS K 7222 standards—trusted benchmarks for foam testing.

Data Connectivity

- Export your results easily with USB or Bluetooth options.

- Seamlessly integrates with your quality control or lab management systems.

Built for Safety and Durability

- Sturdy design made to last in busy testing environments.

- Comes with a solid warranty ensuring peace of mind.

Benefits at a Glance

| Feature | Benefit |

|---|---|

| Digital LCD Screen | Clear, easy-to-read results |

| Auto-Calibration | Consistent accuracy without extra hassle |

| Multi-parameter Output | Saves time by providing complete data |

| USB/Bluetooth Export | Smooth data transfer and integration |

| Anti-Float Technology | Stable, reliable sample measurement |

| Durable Build | Works reliably in industrial settings |

This foam density gauge simplifies testing so you can focus on improving your product quality—fast and accurate.

Technical Specifications

Take a close look at the Derui Foam Density Meter’s specs to see how it fits your testing needs:

| Feature | Specification |

|---|---|

| Weighing Range | 0.1 g to 2000 g |

| Density Accuracy | ±0.001 g/cm³ |

| Sample Size | Minimum 10 cm³ |

| Measurement Capabilities | Density, water absorption, closed pore volume, expansion rate |

| Standards Compliance | ASTM D3574, ISO 1817, JIS K 7222 |

| Display | Digital LCD multi-parameter readout |

| Power Supply | Rechargeable battery or AC adapter |

| Dimensions | 15″ x 12″ x 10″ (LxWxH) |

| Weight | 10 lbs |

What it Measures

- Density: Precise foam density readings per ASTM and ISO standards.

- Water Absorption: Checks how much water the foam takes in during tests.

- Closed Pore Volume: Measures the proportion of closed cells in foam for quality control.

- Expansion Rate: Calculates volume changes when foam expands or contracts.

This mix of specs means faster, reliable testing without manual guesswork. It’s built for US manufacturers who need quick, accurate foam density measurement with easy handling and solid durability.

How It Works: Hydrostatic Weighing Method

The Derui Foam Density Meter uses the hydrostatic weighing method to give you accurate foam density results quickly. Here’s a simple breakdown:

Step-by-Step Guide

- Weigh the Dry Sample: Start by weighing your dry foam sample on the digital scale.

- Submerge in Water: Next, submerge the foam sample in water without trapping air bubbles.

- Weigh Underwater: Measure the sample’s weight underwater to get the buoyant force.

- Calculate Density: Using Archimedes’ principle, the meter calculates the foam’s density based on the difference in weight in air and water.

Archimedes’ Principle Made Easy

This principle states that the buoyant force on an object submerged in liquid equals the weight of the liquid displaced. The meter uses this to figure out the foam’s volume and density without manual conversions, giving you results that meet ASTM D3574 standards.

Tips for Best Results

- Prepare Samples Carefully: Cut foam samples cleanly and avoid tears or holes for accurate volume reading.

- Avoid Air Bubbles: Make sure no air pockets cling to the foam during water submersion.

- Consistent Temperature: Use water at a stable room temperature to avoid measurement errors.

- Read Results Clearly: The digital display shows real-time density values, along with related parameters like water absorption and pore volume.

This method is reliable for polyurethane, sponge, and packing foams, making the Derui Foam Density Meter a smart choice for precise foam quality checks.

Applications and Industries

The Derui Foam Density Meter is built for a wide range of industries where foam quality matters most. Here’s where it shines:

- Furniture & Bedding: Test foam density to ensure comfort, durability, and consistent support. Perfect for mattresses, cushions, and sofas.

- Automotive: Measure cushioning foam density precisely to balance weight and strength, improving safety and ride quality.

- Packaging: Verify packing foam density for effective drop-tests and impact protection, making sure your products arrive safe.

- Medical & Aerospace: Conduct precise foam analysis for specialized polymer foams used in cushions, insulation, and protective equipment.

Real Results: A leading polyurethane foam producer cut testing time in half while improving product quality consistency by using our digital foam density analyzer.

Whether you’re in manufacturing, quality control, or R&D, this foam density gauge delivers the reliable data you need across sectors.

Why Choose Derui Foam Density Meter?

At Derui, we build more than just foam density meters—we deliver reliable, precise tools trusted across the U.S. and worldwide. Our ISO 9001 certification guarantees top-quality manufacturing standards, so every unit meets your expectations for accuracy and durability.

Why Derui Stands Out

| Feature | Derui Foam Density Meter | Basic Scales | Nuclear Gauges |

|---|---|---|---|

| Accuracy | High-precision, ASTM D3574 compliant | Lower precision | Regulatory and safety concerns |

| Ease of Use | Digital readout, auto-calibration | Manual calculations required | Requires special handling |

| Safety | Non-radioactive, safe for workplace | Safe but less specialized | Uses radioactive sources |

| Data Connectivity | USB and Bluetooth integration | Manual data recording | Limited or no connectivity |

| Durability | Rugged build for daily use | Varies, often less durable | Fragile, requires specialized maintenance |

What Customers Say

“The Derui Foam Density Meter cut our testing time in half and gave consistent results every time. It’s simple to use, and the digital display is super clear.”

— Mark R., Foam Manufacturer, USA

“Switching from old scales to Derui’s digital meter was the best move—easier calibration, faster readings, and no safety worries. Highly recommend.”

— Lisa M., Packaging Foam Tester

Trusted Certification and Support

- ISO 9001 Certified: Ensures consistent quality and dependable performance

- ASTM D3574 and ISO 1817 Compliant: Meets industry standards

- Customer Support: US-based service and quick shipping to keep your work moving

Choose Derui for a foam density tester that works for your business, not against it.

Frequently Asked Questions (FAQs)

| Question | Answer |

|---|---|

| What’s the difference between apparent and wet density? | Apparent density is the foam’s mass divided by its total volume, including pores. Wet density measures density while the foam is soaked with liquid, showing how much water it absorbs. |

| How often should I calibrate the Foam Density Meter? | For accurate results, calibrate every 6 months or after heavy use. Use the included calibration kit for best results. |

| Is the Foam Density Meter compatible with silicone foams? | Yes, it works well with most foam types, including silicone. Just follow sample prep instructions for consistent testing. |

| How long does international shipping take? | Shipping to the U.S. usually takes 7-14 business days. Expedited options are available upon request. |

| How does this digital meter compare to manual density methods? | The electronic digital Foam Density Meter offers faster, more accurate readings without guesswork or calculations needed in manual methods like water displacement or weighing. |

If you have more questions, feel free to reach out anytime!

Related Products and Accessories

To get the most out of your Derui Foam Density Meter, consider pairing it with our complementary testers and calibration kits. These tools help you maintain accuracy and expand your foam profiling capabilities.

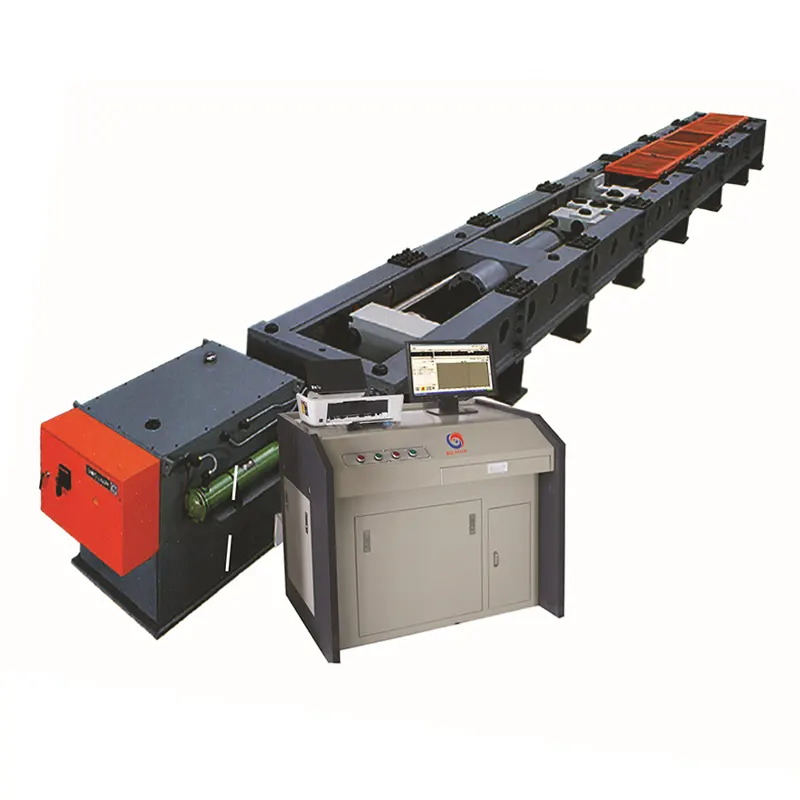

- Foam Air Permeability Tester: Measure how air flows through your foam samples for a full material profile.

- Calibration Kits: Keep your electronic digital foam density meter precise with easy-to-use standard weights and calibration tools.

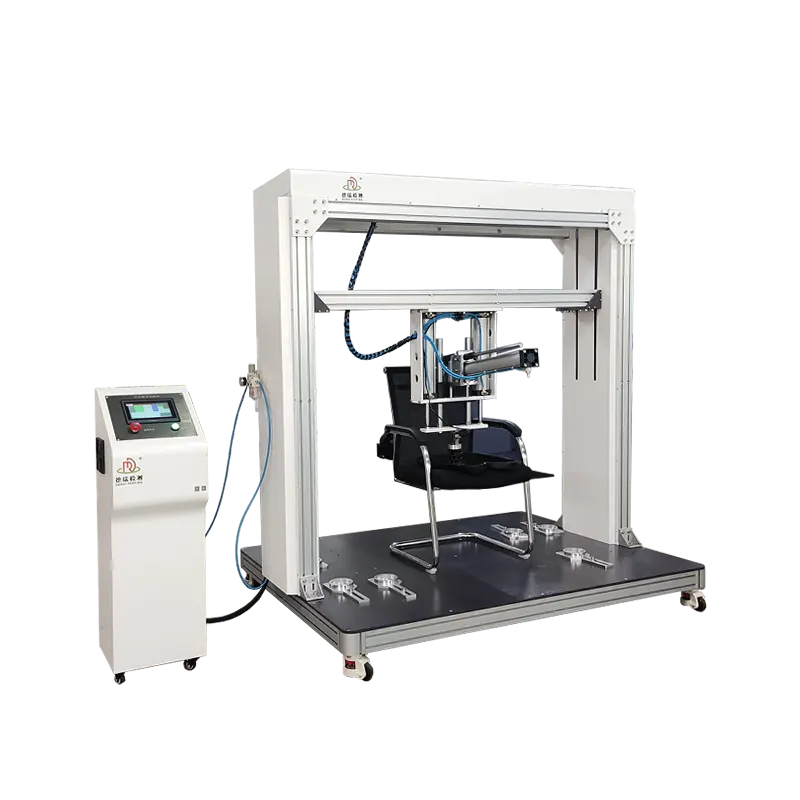

- Foam Hardness Testers: Combine density readings with firmness tests for complete foam quality control.

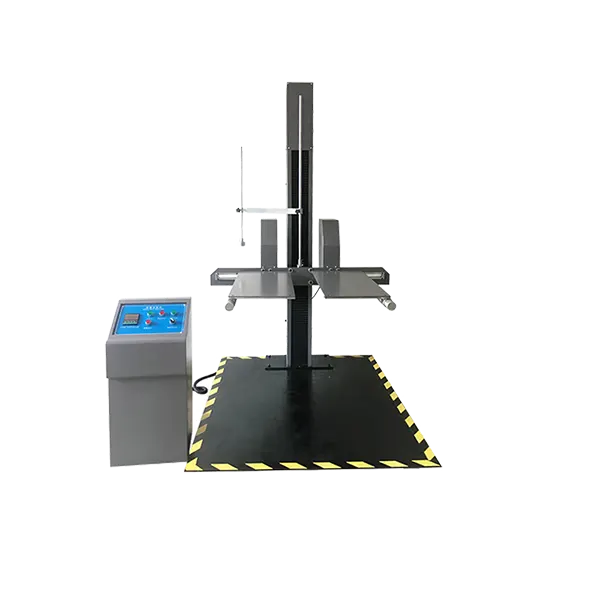

- Packing Foam Drop-Test Equipment: Ensure your packaging materials meet drop-test standards with reliable density verification.

Together, these accessories give you a full suite of foam testing solutions tailored for industries like furniture, automotive, packaging, and medical. Equip your lab with everything needed for accurate, fast, and reliable foam analysis.

Ready to Upgrade Your Foam Density Testing?

Have questions or want to see the Derui Foam Density Meter in action? Reach out today for a free consultation or schedule a demo with our team. We’re here to help you get precise, fast measurements that meet ASTM D3574 and other key standards.

Contact Us:

- Name

- Phone

- Company

- Message

We’re proud to serve customers across the U.S. with quick shipping and reliable support. Join the growing list of manufacturers and quality control experts who trust Derui for consistent foam density testing.

Don’t wait—get accurate results and simplify your foam quality checks now. Contact us today!