What is a Random Vibration Test Machine?

A Random Vibration Test Machine is specialized equipment designed to simulate real-world vibration environments by producing complex, unpredictable vibration patterns. Unlike simple repetitive motions, this equipment replicates the random vibrations products experience during transport, operation, or harsh environmental conditions.

Core Principles and How It Works

- Uses an electrodynamic shaker system or electromagnetic vibration generator.

- Generates vibrations across a broad frequency spectrum simultaneously.

- Controlled by a closed-loop vibration controller to deliver precise vibration profiles.

- Measures vibration output with sensors, adjusting in real-time for accuracy.

This setup mimics natural vibration environments much better than traditional testing methods, which improves product durability and reliability.

Key Differences from Sine and Shock Testing

| Feature | Random Vibration Test | Sine Vibration Test | Shock Test |

|---|---|---|---|

| Vibration Pattern | Broad spectrum, unpredictable | Single frequency, repetitive | Short, high-intensity impact |

| Realism | High, simulates actual use cases | Moderate, cyclic stress | Extreme, sudden events |

| Application Focus | Fatigue and durability analysis | Resonance and natural freq. | Shock resistance and robustness |

Random vibration testing is essential when products face complex, multi-frequency stresses over time, making it critical in aerospace, automotive, and electronics industries.

Applications of Random Vibration Test Machines Across Industries

Random vibration test machines are essential across many industries to ensure products can handle real-world stresses. Here’s a quick look at where and why they’re used:

Aerospace and Defense

These sectors rely heavily on random vibration testing to meet strict standards like NASA-STD-7001A and MIL-STD-810. Aerospace vibration testing machines simulate the intense vibration conditions of flight and launch environments, helping verify the durability and safety of critical components.

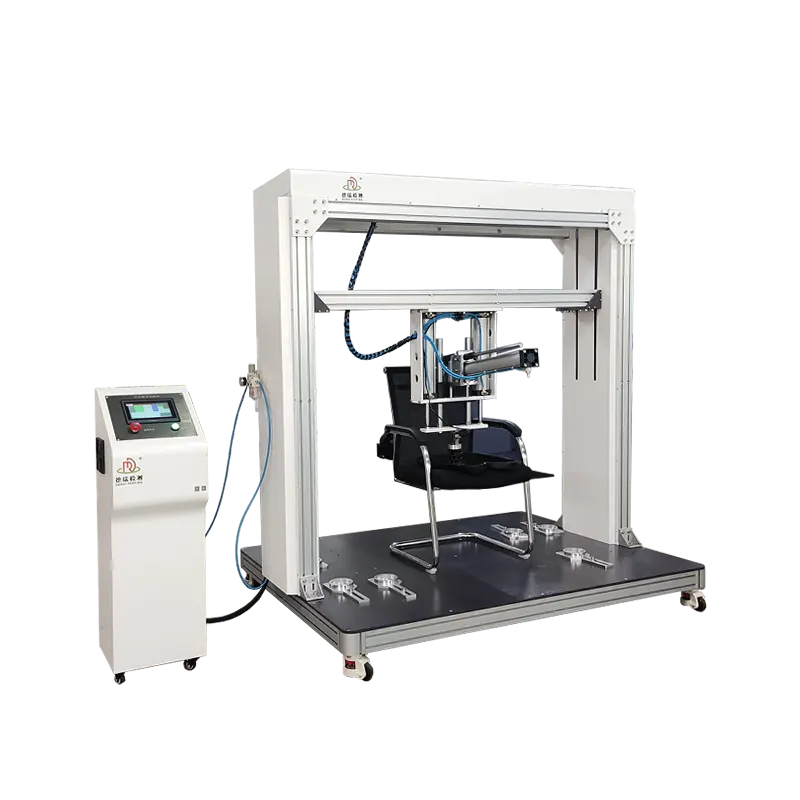

Automotive Electronics

Automotive electronics must withstand constant vibrations on the road. Random vibration testers help manufacturers comply with ISO 16750 standards, ensuring parts like sensors, control units, and infotainment systems stay reliable over time.

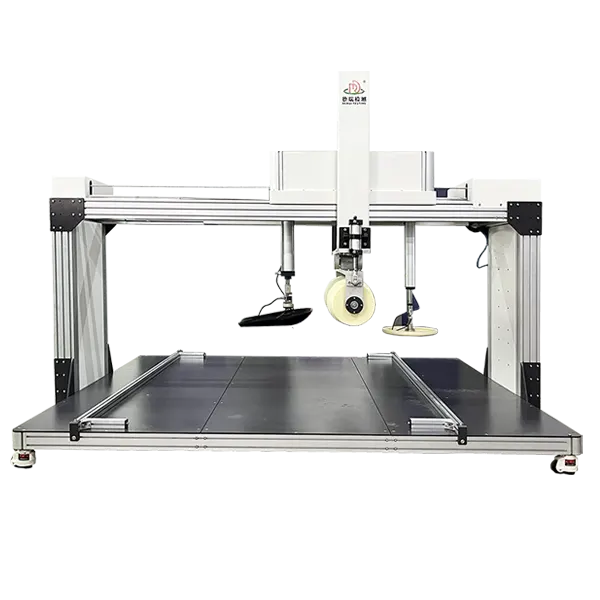

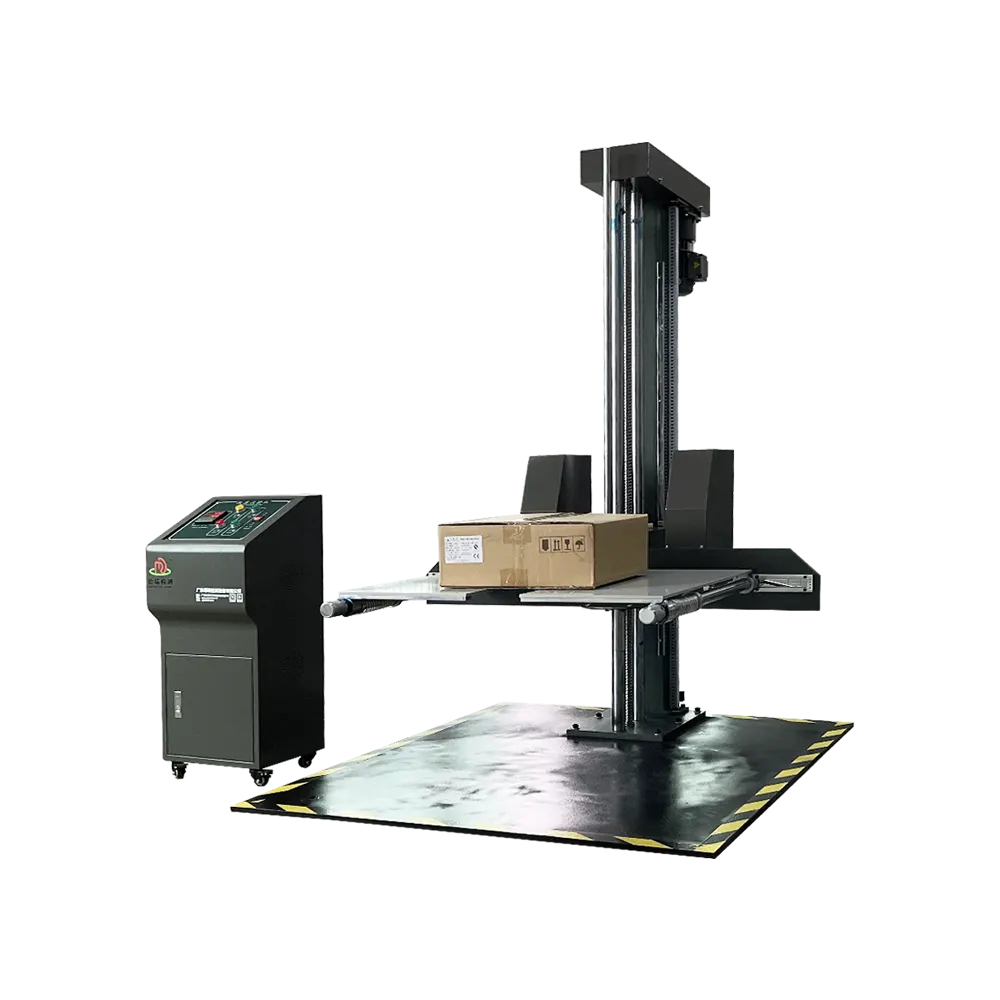

Packaging and Logistics

For packaging and shipping, especially fast-moving e-commerce like Amazon, ISTA 3A and 6 standards are key. Random vibration testing replicates transport simulation vibrations to validate that products and packaging can survive handling, shipping, and drops without damage.

Electronics and Consumer Goods

Many electronics and consumer goods face harsh environments—think vibrations from everyday use, transport, or even industrial settings. Using a random spectrum shaker, manufacturers stress-test these products to boost reliability and reduce failure rates before they hit the market.

This wide range of applications showcases how indispensable vibration simulation equipment is for product development and quality assurance across industries.

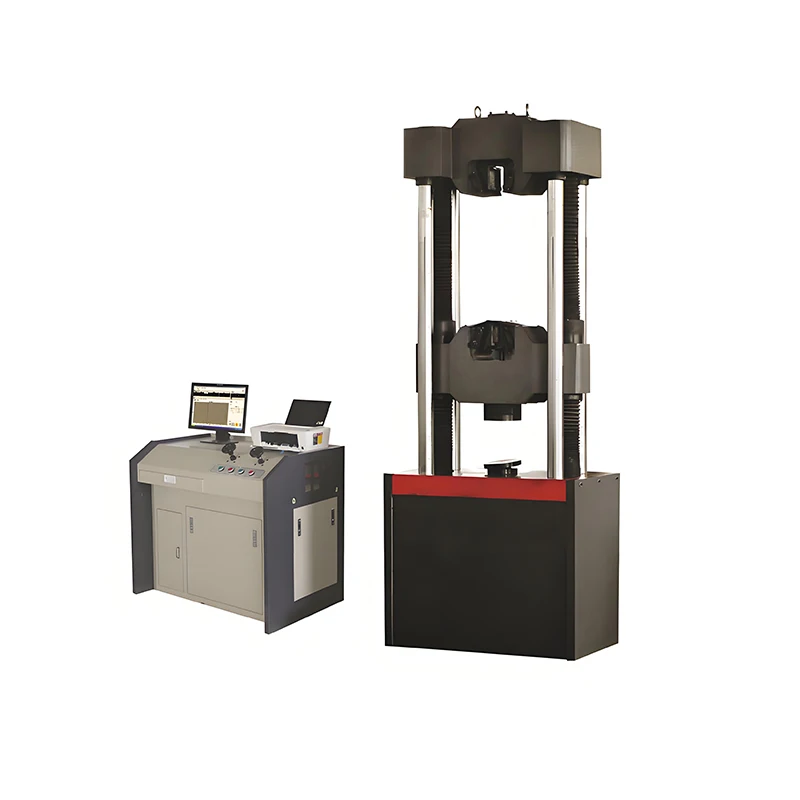

Derui Random Vibration Test Machine Specifications and Models

Derui offers a range of Random Vibration Test Machines designed to fit various testing needs and budgets. Here’s a quick look at the main specs and what you can customize:

| Feature | Description |

|---|---|

| Frequency Range | 5 Hz to 2000 Hz (varies by model) |

| Force Output | 100 lbf to 10,000 lbf |

| Payload Capacity | Up to 1500 lbs |

| Table Size | From 12” x 12” to 48” x 48” |

| Control System | Closed-loop PSD vibration control |

| Axes | Single-axis and multi-axis options |

| Power | Electrodynamic shaker system powered by stable electromagnetic vibration generator |

Customizable Features to Match Your Testing Needs

- Frequency & Force: Choose based on test requirements for aerospace, automotive, or electronics applications.

- Table Size & Payload: Pick from compact to heavy-duty tables depending on product size and weight.

- Control Software: Advanced real-time control with easy-to-use interface tailored for ISTA and MIL-STD-810 testing.

- Multi-axis Testing: Optional multi-axis vibration table for complex vibration simulation.

- Safety Options: Built-in emergency stop, vibration isolation methods, and sound enclosure solutions.

Derui’s lineup is built with flexibility in mind, so whether you’re running compliance tests for automotive electronics or simulating heavy logistics vibrations, there’s a model customizable for you.

Standards and Compliance for Random Vibration Testing

When it comes to random vibration testing, meeting the right safety and performance standards is crucial. These standards ensure that your products can handle real-world conditions while keeping users safe and complying with industry regulations.

Essential Safety and Performance Standards

- MIL-STD-810: Widely used in aerospace and defense, this military standard outlines rigorous tests for environmental engineering, including random vibration.

- NASA-STD-7001A: Specific to aerospace, it sets tough criteria for vibration testing to ensure space-grade durability.

- ISO 16750: Focused on automotive electronics, this standard ensures devices withstand vibration during vehicle operation.

- ISTA 3A/6-Amazon: Important for packaging and logistics, these help simulate transport vibrations to keep goods safe during shipping.

- Other industry-specific norms apply depending on the product, including FDA, IEC, and DOT standards.

How Derui Ensures Full Compliance

At Derui, we design our random vibration test machines to fully comply with all major standards relevant to the U.S. market and global requirements. Here’s how:

- Built-in Closed-Loop Vibration Controllers: Our systems maintain precise PSD vibration control, matching test profiles exactly to required standards.

- Wide Frequency Range and Force Output: This ensures your testing covers everything from delicate electronics to heavy-duty aerospace equipment.

- Custom Test Profiles: Easily programmed to reflect the specific vibration spectra mandated in MIL-STD-810, ISO 16750, or ISTA guidelines.

- Comprehensive Documentation: We provide all necessary test reports and calibration certificates to verify compliance.

- Routine Calibration and Support: Derui offers ongoing calibration services and technical support to keep your vibration tester operating at peak standards.

By ensuring your vibration testing equipment meets these regulations, Derui helps you deliver products that are safe, reliable, and market-ready.

Choosing the Right Random Vibration Tester: Buyer’s Guide

Picking the right random vibration test machine can be tricky, but focusing on a few key factors makes it easier:

- Frequency Range: Make sure the tester covers the vibration frequencies your product will face in real life. For automotive electronics or aerospace parts, this range can vary widely, so check specs carefully.

- Force Output: The strength of the vibration matters. Higher force output means you can test heavier or more robust samples thoroughly. This is crucial for bulkier equipment or automotive components.

- Payload Capacity: Know your product size and weight. Your vibration tester should comfortably handle the maximum load without losing accuracy or performance.

Derui vs. Competitors: What Sets Us Apart

Choosing Derui means you’re investing in quality and reliability designed with the U.S. market in mind. Here’s why we stand out:

- Customizable Options: We tailor features like multi-axis vibration control and PSD vibration simulation to fit specific industry needs—from aerospace to packaging testing.

- Robust Build: Derui machines are built tough to meet tough standards like MIL-STD-810 and ISTA 3A, ensuring your tests are both accurate and repeatable.

- User-Friendly Interface: Our closed-loop vibration controllers are easy to set up and operate, saving you time during tests and minimizing downtime.

- Comprehensive Support: From installation to routine maintenance, we offer full support, so you’re never left in the dark.

If you want a random vibration tester that balances precision, capacity, and ease of use—Derui has you covered.

Installation, Operation, and Maintenance Best Practices

Getting your Random Vibration Test Machine up and running smoothly is key to accurate and reliable vibration testing. Here’s how to set up, operate, and maintain your equipment for the best results.

Step-by-Step Setup for Optimal Performance

- Choose the Right Space: Ensure a solid, vibration-isolated foundation to minimize external interference.

- Secure the Machine: Anchor the shaker system firmly to avoid movement during tests.

- Connect Power and Controls: Use the recommended power supply and hook up the closed-loop vibration controller properly.

- Mount the Test Item Correctly: Attach your payload securely to the fixture to avoid slippage or damage.

- Load the Test Profile: Program the PSD vibration control or random spectrum shaker settings based on your testing standards (like MIL-STD-810 or ISO 16750).

- Run a Trial Test: Start at low force output, watch for unusual noises or movement, then increase gradually to test parameters.

Routine Calibration and Troubleshooting

- Calibration Checks: Perform routine calibration using certified sensors and analyzers like a fatigue vibration analyzer to keep accuracy in check.

- Inspect Mechanical Parts: Regularly check for wear on mounts, fixtures, and armatures; replace anything worn out to prevent downtime.

- Controller Updates: Keep firmware and software of your closed-loop controller current for best performance and compatibility.

- Troubleshoot Common Issues:

- Unexpected noise? Check for loose mounts or damaged components.

- Test failure or erratic vibration? Verify signal connections and sensor calibration.

- Power irregularities? Inspect electrical supply and grounding.

Following these steps ensures your Random Vibration Tester stays reliable and ready, letting you meet industry standards without delays or costly repairs.

Frequently Asked Questions About Random Vibration Test Machines

Q: What is a random vibration tester used for?

A: It simulates real-world, unpredictable vibrations to test the durability of products like electronics, automotive parts, and packaging during transport or operation.

Q: How does a random vibration test machine differ from sine or shock testing?

A: Unlike sine testing, which uses single frequencies, and shock testing, which applies sudden impacts, random vibration testing applies a range of frequencies at once, reflecting actual operating conditions.

Q: What industries rely on random vibration testing?

A: Aerospace, automotive electronics, packaging and logistics, and consumer electronics are the main users. They need to meet standards like MIL-STD-810, ISO 16750, and ISTA 3A/6-Amazon.

Q: How important is compliance with standards like MIL-STD-810 or ISO 16750?

A: Extremely important. Compliance ensures your products can withstand industry-specific vibration conditions and pass quality checks.

Q: Can Derui’s random vibration test machines be customized?

A: Yes. We offer models with adjustable frequency ranges, payload capacities, and control systems like PSD vibration control and closed-loop controllers to fit your testing needs.

Q: What kind of maintenance do these machines require?

A: Routine calibration, vibration controller checks, and troubleshooting are essential to keep performance consistent.

Q: How do I choose the right random vibration tester?

A: Consider frequency range, force output, payload capacity, and compliance with your industry standards. Derui’s equipment offers reliable options that stand out from competitors.

If you have more questions or want to see how our random vibration test machines fit your needs, reach out anytime!

Why Partner with Derui for Your Vibration Testing Needs?

When it comes to random vibration test machines, Derui stands out as a trusted choice for U.S. businesses. We combine manufacturing excellence with a deep understanding of what American industries need—durability, precision, and compliance. Our machines are built to meet strict standards like MIL-STD-810 and ISO 16750, ensuring your products pass critical vibration tests every time.

Manufacturing Excellence and Global Support

Derui’s random vibration testers feature robust electrodynamic shaker systems and advanced PSD vibration control for accurate simulation. We focus on reliability and easy integration into your testing lab or production line. Plus, our global support team is ready to assist with everything from installation to routine maintenance—no matter where you are in the U.S. or beyond.

Get Started Today – Quotes, Demos, and Financing

Ready to take your vibration testing to the next level? We make it simple to get started. Contact us for a personalized quote, schedule a hands-on demo to see our equipment in action, or explore flexible financing options designed to fit your budget. Partner with Derui and ensure your products meet durability and safety standards with confidence.