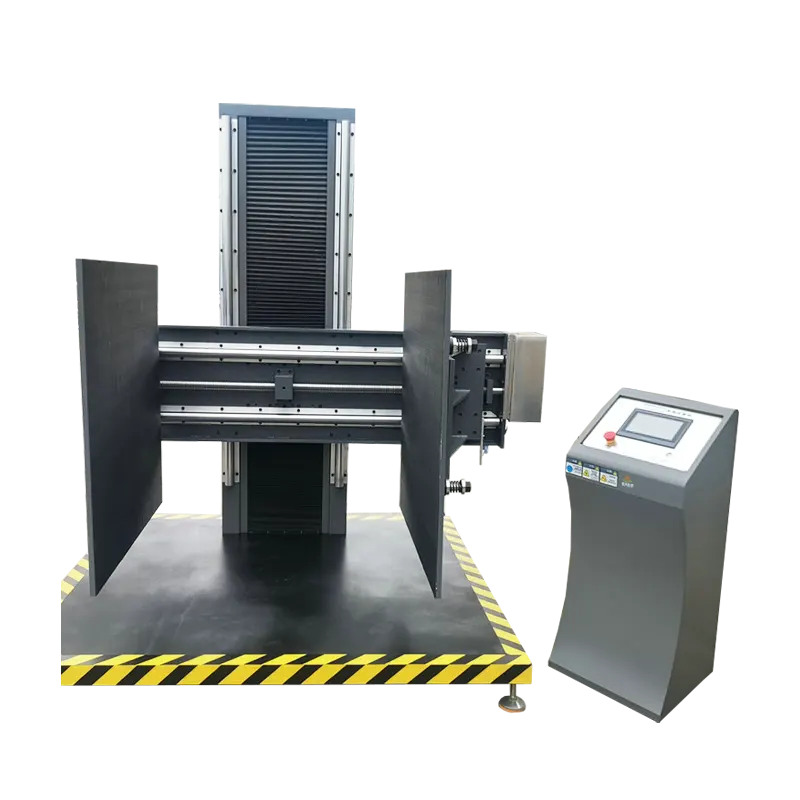

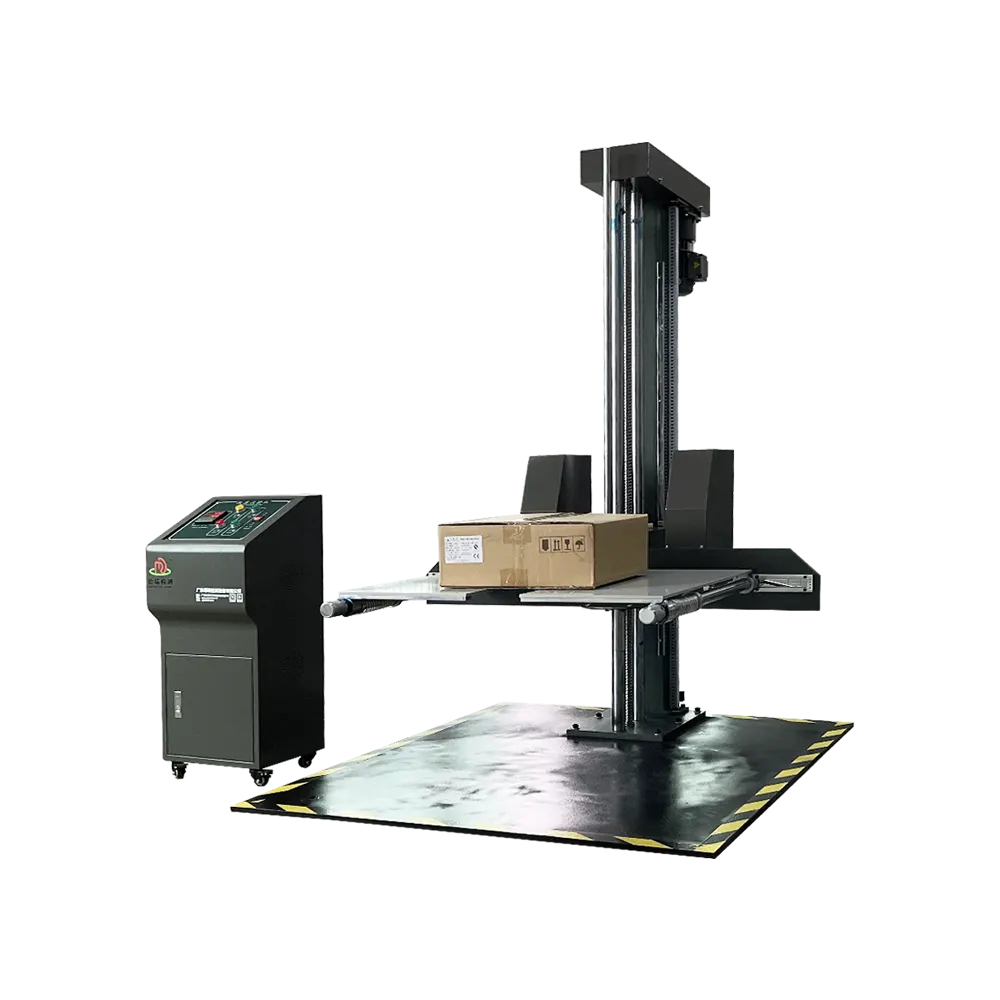

Packaging Clamping Force Testing Machine

Ensure your packaging stands up to real-world logistics with our advanced Packaging Clamping Force Testing Machine. Designed to simulate actual clamp truck forces, this system delivers precise and reliable performance. Fully compliant with ISTA 6-Amazon and key ASTM standards, it ensures your packaging meets the toughest industry requirements.

Our machine features dual servo control for smooth, accurate force application, paired with an intuitive touch-screen PLC and PC software interface for seamless operation and data management. Trusted by Fortune 500 companies worldwide, it’s the ideal solution for packaging engineers and procurement specialists seeking proven quality and dependable testing results.

Experience cutting-edge clamp simulation testing—engineered for accuracy, compliance, and ease.

Product Overview & Applications

A packaging clamping force testing machine measures the force used when a clamp truck or forklift grips your products during handling and shipping. This test simulates real-world clamping pressure to make sure your packaging holds up without being crushed or damaged. It’s a key step in verifying package strength and ensuring goods arrive safely.

Clamping simulation is crucial for industries where products are transported on pallets or in cartons that get gripped by forklifts or pallet clamps. It helps prevent over-tightening that can crush contents or under-tightening that causes product shifting.

Typical industries using this testing machine include:

- Warehousing and logistics

- Food and beverage distribution

- Electronics manufacturing

- Consumer goods packaging

- Pharmaceutical shipping

Common test objects are palletized loads, cartons, boxes, crates, and any packaged goods that face clamping during transit. This testing machine helps you replicate the forces your products will experience in a real supply chain scenario, boosting confidence in your packaging design and warehouse handling procedures.

Standards Compliance for Packaging Clamping Force Testing Machine

Our packaging clamping force testing machine meets all key industry standards, making it a reliable choice for quality assurance in the U.S. market. It fully complies with ISTA 6-Amazon Member Test requirements, ensuring your packages can handle Amazon’s strict clamping force guidelines.

In addition, it supports ASTM standards like ASTM D6055 (pallet unit load testing), ASTM D4169 (performance testing of shipping containers), and ASTM D999 (vibration standards often used alongside clamp testing). This means you get trusted, repeatable results that stand up to rigorous testing protocols.

Beyond ASTM, our machine aligns with international standards such as ISO 2234, EN 15552 (European clamp testing), and China’s GB/T 4857 standard for packaging testing. This broad compliance means you’re covered whether you’re shipping domestically or internationally.

Using a clamp simulation testing machine that adheres to these standards helps prevent package damage during warehouse handling, reducing losses from crushed or distorted goods. Compliance guarantees your testing meets customer, carrier, and regulatory expectations every time.

Key Features & Technical Advantages of Packaging Clamping Force Testing Machine

Our Packaging Clamping Force Testing Machine packs powerful features designed for accurate, reliable testing:

- Two Test Modes: Switch easily between clamping force simulation and compression testing for versatile use.

- High-Rigidity Structure: Built to stay stable and precise under heavy loads, ensuring consistent measurement.

- Imported Load Cell & Servo Motor: Top-grade components deliver precise force readings and smooth operation.

- Automatic Platen Adjustment: Quickly adapt platen spacing to fit various package sizes without manual hassle.

- Advanced Safety Features: Includes emergency stop, overload protection, and safety guards to protect users and equipment.

| Feature | Benefit |

|---|---|

| Dual Test Modes | More testing options in one machine |

| Sturdy Frame Design | Stable, accurate results over long tests |

| High-Precision Sensors | Reliable force measurement |

| Auto Platen Adjustment | Saves setup time, fits different packages |

| Safety Systems | Keeps operators and machine safe |

These advantages make the machine perfect for simulating real forklift clamp forces or warehouse pallet clamping, giving you trustworthy data every time.

Technical Specifications of Packaging Clamping Force Testing Machine

| Specification | DR-L1000 | DR-L2000 |

|---|---|---|

| Max Clamping Force | 1,000 kgf (9.8 kN) | 2,000 kgf (19.6 kN) |

| Platen Size | 600 x 600 mm | 800 x 800 mm |

| Adjustable Space | 50 – 400 mm | 50 – 600 mm |

| Force Accuracy | ±0.5% | ±0.5% |

| Control System | Dual Servo Control + Touchscreen PLC & PC Software | Dual Servo Control + Touchscreen PLC & PC Software |

| Power Supply | 220V, 50/60 Hz | 220V, 50/60 Hz |

- Both models come with high-precision imported load cells and servo motors.

- Automatic platen adjustment makes setup quick and easy.

- Easy-to-use software offers real-time monitoring and detailed report exporting.

- Designed to meet ASTM, ISTA, and ISO testing standards for reliable, repeatable results.

These specs ensure the Derui packaging clamping force testers fit a variety of package sizes and testing needs, perfect for users looking to simulate real forklift or cart clamp forces accurately.

Testing Process & Software

Using the Packaging Clamping Force Testing Machine is straightforward and designed for clear results. Here’s how it works:

- Step-by-step setup: Position your packaging sample between the platens, select the test mode on the touch-screen PLC, and input your test parameters.

- Real-time monitoring: During testing, you can watch force and displacement curves live on the screen, giving instant insight into how the package responds under clamp truck forces.

- Data handling: The system records all test data automatically. You can export detailed reports in common formats like Excel or PDF to analyze or share with your team.

- User-friendly software: The PC software interface makes it easy to manage tests, track trends, and generate compliance reports for ISTA 6-Amazon, ASTM, and other standards.

This setup streamlines your packaging clamp force testing, helping you confidently measure and improve package durability for real-world logistics scenarios.

Optional Accessories for Packaging Clamping Force Testing Machine

To make your packaging clamp force tester even more versatile, we offer several optional accessories tailored to meet different testing needs:

- Larger Platens: Ideal for testing bigger packages or multi-unit pallets, giving you more surface area for accurate clamping force measurement.

- Angle-Adjustable Platens: These let you simulate clamp forces at different angles, perfect for replicating real-world forklift and clamp truck scenarios.

- Environmental Chamber Interface: Connect your clamp simulation testing machine to temperature and humidity chambers for testing packaging durability under various environmental conditions.

- Video Recording System: Capture every test in action with high-quality video, helping you analyze clamp behavior and provide detailed test documentation.

These add-ons ensure your packaging clamping force testing equipment stays flexible and efficient, ready to cover a wide range of industry requirements.

Case Studies & Customer Stories: Trusted by Industry Leaders

Our Packaging Clamping Force Testing Machine has been a go-to solution for major players like Amazon Fulfillment, Coca-Cola, Procter & Gamble, and Samsung Logistics. Here’s how it helped:

- Amazon Fulfillment: Used our clamp truck simulation tester to verify carton clamp forces, ensuring packages withstand real warehouse handling without damage.

- Coca-Cola: Relied on our packaging clamp force tester to confirm bottle packs hold securely during pallet transport, preventing costly product loss.

- Procter & Gamble (P&G): Applied the machine to simulate clamping loads on various consumer goods packaging, meeting strict ISTA 6-Amazon standards.

- Samsung Logistics: Utilized our pallet clamping force tester for reliable testing of electronic goods packaging, assuring safety during shipping.

These stories prove our clamping load measurement system works across industries, helping top companies meet packaging durability standards and reduce damage risk.

Why Choose Derui Packaging Clamping Force Testing Machines

When it comes to packaging clamping force testing machines, Derui stands out with more than 20 years of experience serving U.S. businesses. Here’s why we’re the trusted choice:

| Feature | Why It Matters |

|---|---|

| 20+ Years Experience | Proven expertise in clamp simulation testing and packaging quality assurance. |

| CE & ISO Certifications | Meets international safety and quality standards, giving you peace of mind. |

| Warranty & Lifetime Support | We back our machines with reliable warranties and ongoing technical support to keep you running. |

| Fast Delivery | Quick shipping across the U.S. means your clamp testing system arrives when you need it. |

Choosing Derui means you get durable, precise, and compliant packaging clamp force testers tailored for the American market. Our machines help you simulate real clamp truck forces and keep your packaging up to ISTA 6-Amazon & ASTM standards without a hitch. We’re here to support your business every step of the way.

FAQ: Packaging Clamping Force Testing Machine

| Question | Answer |

|---|---|

| What’s the difference between clamping and compression tests? | Clamping tests simulate forces from forklifts or clamp trucks squeezing packages. Compression tests measure how much weight a package can handle stacked vertically. Both ensure packaging strength but focus on different stress types. |

| How does this machine meet ISTA 6 requirements? | Our tester complies fully with ISTA 6-Amazon standards, replicating real clamp truck forces for certified testing. It’s also compatible with ASTM and other industry standards. |

| Can it handle pallet load testing? | Yes, it’s designed for pallet clamping force testing and simulates forklift clamp pressure accurately to ensure pallets and wrapped loads stay secure. |

| What’s the typical lead time and pricing? | Lead times usually range from 4 to 6 weeks, depending on model and accessories. Pricing varies based on specifications but we offer competitive quotes tailored to your needs. Contact us for details. |

Need more info? Reach out anytime— we’re here to help with your packaging clamp force testing needs!

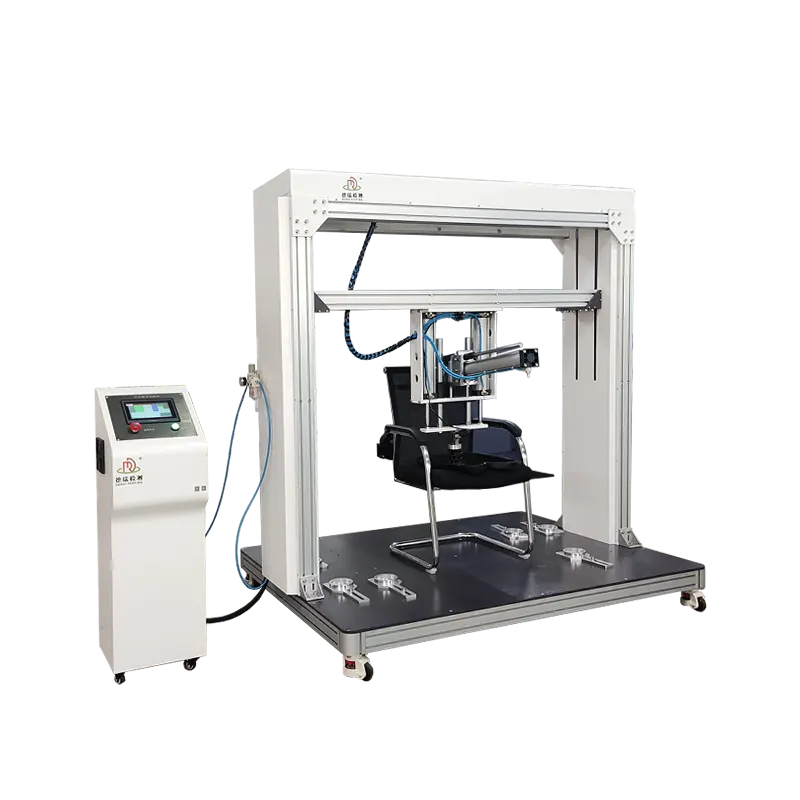

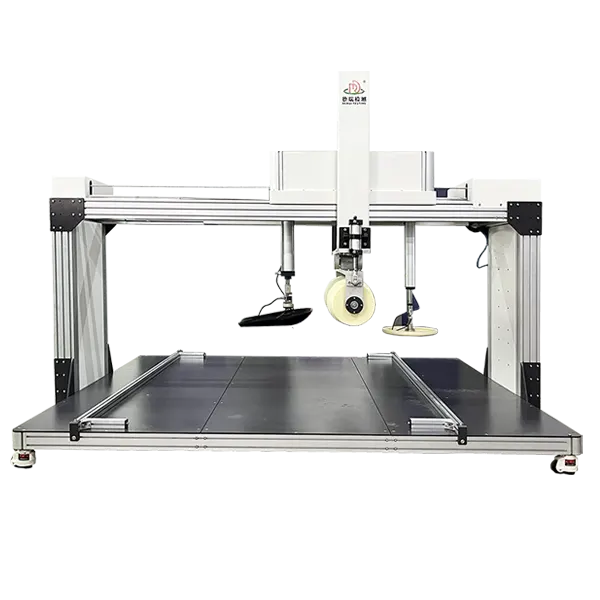

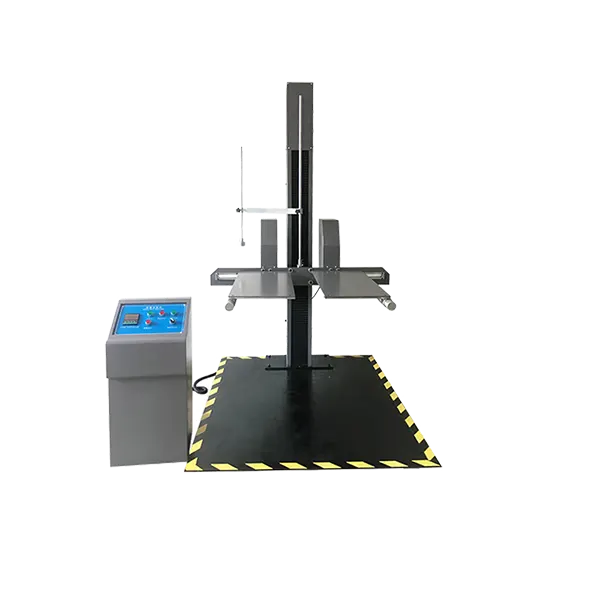

Related Products for Packaging Testing

Along with our Packaging Clamping Force Testing Machine, we offer a range of reliable testing equipment to cover all your package durability needs:

- Drop Tester: Simulates real-world drops and impacts to check package strength.

- Vibration Tester: Replicates transportation vibrations to assess product and package stability.

- Compression Tester: Measures how much weight or pressure a package can handle before deforming.

- Incline Impact Tester: Tests the resistance of packages against sliding and blunt impact during handling.

Each machine is designed to work seamlessly with your packaging tests, helping ensure your products meet industry standards and arrive safely to customers.

Download Center: Brochures, Protocols & Test Reports

Easily access everything you need to evaluate our Packaging Clamping Force Testing Machine.

- Product Brochures: Detailed specs, features, and benefits at a glance.

- Test Protocols: Step-by-step guides covering ISTA 6-Amazon, ASTM D6055, and other standards.

- Sample Test Reports: Real-world results from our clamp simulation testing machines for quick reference.

All files are ready to download in PDF format—perfect for engineers, QA teams, and purchasing decisions. Stay informed and confident with our full set of resources designed for U.S. businesses focused on packaging clamp force testing and compliance.