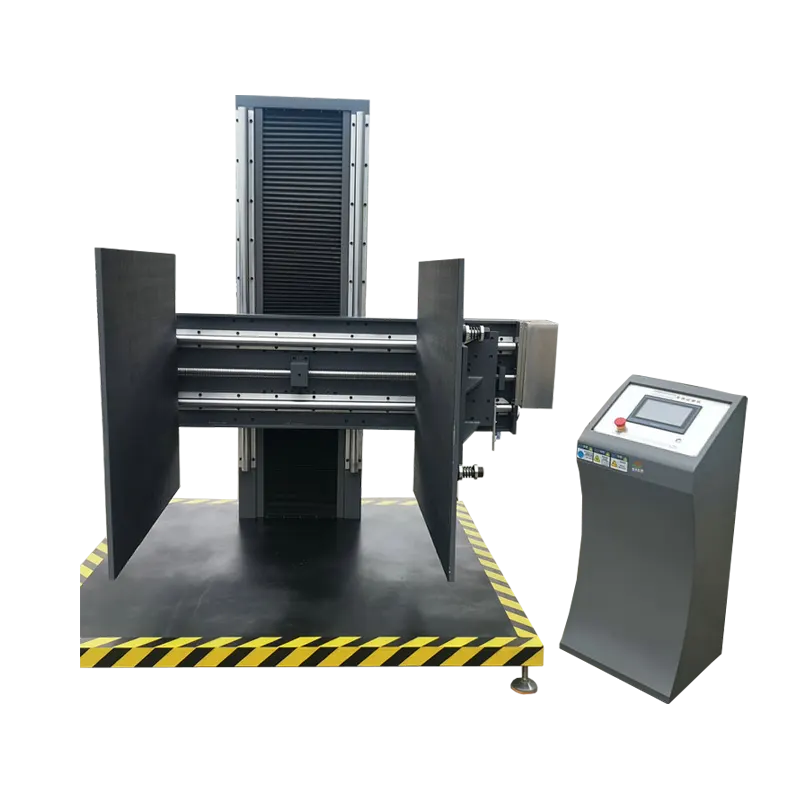

An office chair rotation fatigue tester is a specialized testing device designed to simulate the frequent rotational movements of office chairs during actual use. It is primarily used to evaluate the structural stability, durability, and reliability of key components (such as rotating shafts, bearings, and connecting parts) of office chairs—especially those with rotating functions (e.g., bases or star feet)—under long-term rotational stress. Below is a detailed introduction covering its purpose, working principle, technical parameters, testing standards, and application scenarios:

I. Primary Purposes

- 1.Quality Verification: Detect whether the rotating function of an office chair exhibits issues such as loosening, abnormal noise, sticking, or structural failure (e.g., shaft breakage, base cracking) after prolonged use.

- 2.R&D Optimization: Assist manufacturers in improving the design of rotating mechanisms (e.g., bearing materials, lubrication processes, shaft strength) to enhance product durability.

- 3.Compliance Testing: Ensure the product meets market access requirements by fulfilling domestic and international furniture safety standards (e.g., BIFMA, GB/T 3326, EN 1335) regarding rotational fatigue performance.

- 4.Lifespan Assessment: Predict the performance degradation trend of office chairs over their normal service life by simulating high-frequency rotations.

II. Working Principle

The instrument simulates manual rotational movements through a mechanical drive system, applying periodic loads to the rotating parts of the office chair (typically the connection shaft between the star foot and the tray) while monitoring key parameters. The core process includes:

- 1.Fixing the Chair: Securely mount the office chair on the test stand, ensuring the rotating axis is aligned concentrically with the drive mechanism (to avoid off-center loading that could skew results).

- 2.Driving Rotational Motion: Use an electric motor or pneumatic device to rotate the chair at a preset speed (e.g., 10–30 rotations per minute), simulating frequent turning actions in daily use (e.g., when a person stands up or adjusts their sitting posture).

- 3.Load Simulation: Some advanced models can apply additional vertical/horizontal loads (e.g., simulating human weight, typically 200–1000 N, equivalent to 30–150 kg pressure) to more realistically replicate real-world usage scenarios.

- 4.Data Monitoring and Recording: Continuously collect data such as rotation cycles, torque variations, abnormal noise frequency, and component displacement until the preset number of tests is reached (e.g., 10,000, 50,000, or even 1,000,000 cycles) or until the chair shows significant failure (e.g., rotational sticking, abnormal noise exceeding specified decibel levels, or excessive wear on the rotating shaft).

III. Key Technologies and Parameters

While specific parameters may vary by model, core specifications typically include:

- •Rotation Speed Range: 5–50 rotations per minute (adjustable, covering common rotational frequencies in office settings).

- •Maximum Test Cycles: 10,000 to 1,000,000 cycles (set according to standards or client requirements).

- •Loading Capacity: Vertical static load (simulating human weight) usually ranges from 200 N to 2000 N (approximately 20–200 kg), with some models supporting dynamic load simulation.

- •Rotation Angle: 360° continuous rotation (full-directional testing) or limited-angle rotation (e.g., ±90° back-and-forth).

- •Drive Method: Servo motors (for precise control of speed and force), pneumatic devices (suitable for heavy loads), or mechanical cranks (low-cost, simple models).

- •Monitoring Functions: Torque sensors (to detect changes in rotational resistance), sound level meters (to monitor abnormal noise), displacement sensors (to observe component loosening), and counters (to track rotation cycles).

- •Safety Features: Overload shutdown, emergency stop button, and anti-toppling fixation devices (to ensure safe testing).

IV. Applicable Standards

The design of the tester typically references the following domestic or international standards:

- •Domestic Standards:

- •GB/T 3326-2016 Office Chairs(basic requirements for rotational mechanism flexibility and durability).

- •QB/T 2280-2016 Office Chairs(specific methods for rotational fatigue testing).

- •International Standards:

- •BIFMA X5.1 (U.S. Business and Institutional Furniture Manufacturers Association standard): Requires rotational mechanisms to withstand 50,000 cycles without functional failure.

- •EN 1335 (European Office Furniture Standard): Specifies that rotational fatigue tests must simulate actual usage loads to evaluate structural integrity.

- •ISO 24496 (International Organization for Standardization): Outlines testing methods for the durability of rotating components in office seats.

V. Application Scenarios

- 1.Furniture Manufacturers: Used for production-line sampling or durability validation during new product development to ensure product quality meets standards.

- 2.Third-Party Testing Labs: Provide compliance certification services for clients (e.g., BIFMA, CE certification) regarding office chair rotational performance.

- 3.Quality Inspection Departments: Conduct quality spot checks on office chairs in circulation for market regulators or industry authorities.

- 4.R&D Laboratories: Analyze the impact of different materials (e.g., nylon shafts vs. metal shafts) or lubrication solutions (e.g., grease types) on rotational lifespan to optimize product design.

VI. Purchasing Recommendations

When selecting an office chair rotation fatigue tester, focus on the following:

- •Compatibility: Choose a model tailored to the type of chair being tested (e.g., standard rotating chairs, heavy-duty executive chairs, height-adjustable rotating chairs) based on loading capacity and rotation range.

- •Precision and Automation: Prioritize instruments with automatic data recording and curve analysis functions to reduce human error and improve testing efficiency.

- •Scalability: Some testers support multi-station simultaneous testing (testing multiple chairs at once), ideal for batch validation needs.

- •Brand and Service: Opt for suppliers with experience in furniture testing equipment (offering standard customization, after-sales maintenance, and calibration services).