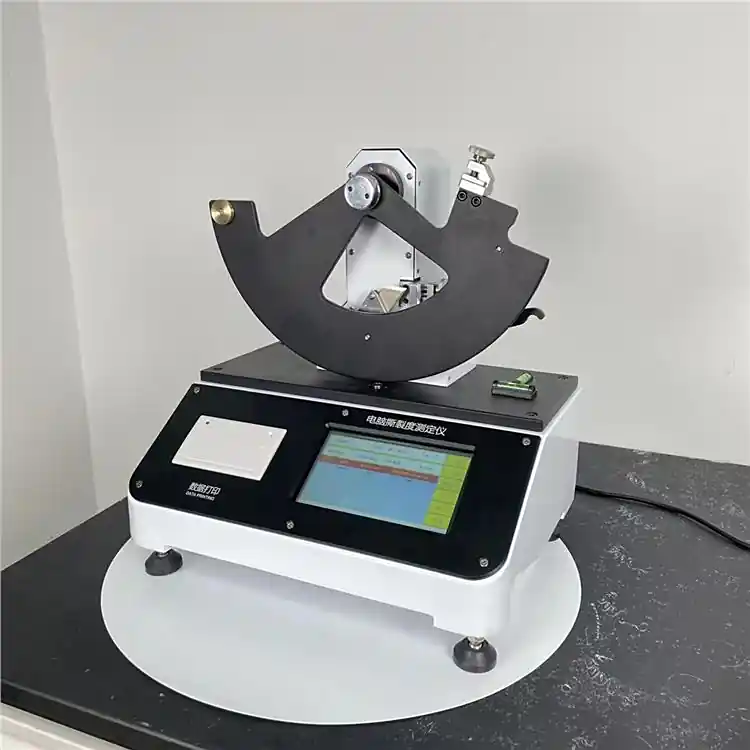

Why Choose Derui’s Martindale Abrasion and Pilling Tester

If you’re looking to evaluate fabric durability and pilling resistance accurately, Derui’s Martindale Abrasion and Pilling Tester stands out. Based on the widely accepted Martindale method—used globally for fabric abrasion testing—our machine combines precision with ease of use.

What is the Martindale Method?

The Martindale method simulates real-life rubbing by moving fabric samples in a complex Lissajous pattern until wear or pilling appears. This makes it ideal for testing textiles, upholstery, leather, and more. Derui enhances this method with innovations such as digital controls and multi-station setups to boost efficiency and reliability.

Why Derui?

- Reliable R&D Data: Gain accurate wear resistance results to develop better textiles.

- Manufacturing Control: Quickly identify weak batches for quality assurance.

- Compliance Assurance: Meet strict USA and international standards (ISO 12947, ASTM D4966) with confidence.

What Our Users Say

“Derui’s Martindale tester streamlined our fabric testing process. The precision and user-friendly interface let us meet compliance goals and speed up product launches.” — Quality Manager, Textile Manufacturer

Choosing Derui means investing in proven technology and dependable service that supports your product quality from lab to production line.

Key Features and Technical Specifications

Our Derui Martindale Abrasion and Pilling Tester is built for efficiency and accuracy with features designed to support a range of testing needs in the U.S. textile market.

Multi-Station Configurations & Digital Interface

- Choose 4, 6, or 9 test stations to handle multiple samples at once.

- Easy-to-use digital control panel with clear display for setting test parameters and tracking progress.

- Integrated automatic abrasion counter improves testing accuracy and convenience.

Precision Lissajous Motion System

- Utilizes a proven Lissajous figure motion to apply uniform abrasion or pilling actions.

- Ensures consistent wear and pilling simulation, mimicking real-life fabric use.

- Delivers high repeatability for reliable R&D and quality control.

Sample Holders & Safety Features

- Adjustable, stable sample holders fit various fabric types, including woven, knit, leather, and nonwoven materials.

- Built-in safety covers protect operators from moving parts during testing.

- Emergency stop button for quick shutdown if needed.

Technical Specifications Table

| Feature | Specification |

|---|---|

| Test Stations | 4 / 6 / 9 |

| Motion Type | Lissajous elliptical |

| Stroke Length | 38 mm (standard) |

| Stroke Frequency | 55 ± 1 cycles/min |

| Load Range | 9 kPa to 12 kPa |

| Sample Size | 38 mm diameter |

| Digital Counter | Automatic, counts abrasion cycles |

| Power Supply | 110V/220V, 50/60 Hz |

| Dimensions | Varies by model (Mini, Midi, Maxi) |

| Safety | Protective covers, emergency stop |

This combination of features makes the Derui Martindale Abrasion Tester a dependable choice for U.S. manufacturers and labs requiring precise, compliant fabric wear and pilling testing.

Applications in Textile and Material Testing

The Derui Martindale Abrasion Tester is built to handle a wide range of textile and material testing needs. Whether you’re working with cotton, wool, synthetics, or blends, it accurately measures fabric abrasion resistance to help ensure durability in everyday use.

For pilling assessment, this tester meets well-known standards, providing clear grading to evaluate how fabrics will perform over time without those annoying little fuzz balls forming.

Beyond textiles, this machine is strong at specialty testing for materials like leather, carpets, and automotive fabrics. It’s perfect for manufacturers needing to check wear resistance in seats, interior trims, and commercial textiles.

Common industries using our Martindale wear tester include apparel, upholstery, automotive, and carpet manufacturing. Stay tuned for case studies showing how businesses improved product quality and cut costs with precise abrasion and pilling testing.

How the Derui Martindale Wear Tester Works

Getting reliable results with the Derui Martindale Abrasion and Pilling Tester is straightforward. Here’s a quick step-by-step guide to make the most of it:

Step 1: Specimen Preparation and Setup

- Cut your fabric sample according to the required size, usually a standard circular shape.

- Attach the sample firmly to the appropriate sample holder—whether for fabric, leather, or nonwoven materials.

- Choose the right abrasive surface (wool, sandpaper, or another consumable) based on your testing needs.

- Load multiple stations if you have the multi-station version to run several samples at once.

Step 2: Running Tests and Monitoring Endpoints

- Set test parameters like the number of cycles and abrasion or pilling mode on the digital interface.

- Start the machine to begin the precise Lissajous motion rubbing pattern designed to simulate real wear.

- Watch the automated counter and system alerts for endpoint achievement based on your test specifications.

- You can pause or stop the test anytime to inspect samples mid-test if needed.

Step 3: Evaluating Results and Pro Tips for Accuracy

- Remove samples carefully to avoid new damage before assessment.

- Use visual grading or digital image analysis for pilling and wear assessment, following ASTM D4966 or ISO 12947 guidelines.

- To get consistent results:

- Ensure the sample is mounted evenly without wrinkles.

- Calibrate the machine regularly with Derui’s traceability certificates.

- Run multiple cycles and replicate tests for reliability.

By following these steps, you can trust the Derui Martindale wear tester to give consistent, standardized abrasion and pilling resistance results that align with industry compliance.

Compliance and Standards for Reliable Results

When it comes to fabric abrasion testing, meeting recognized standards is crucial. Our Derui Martindale Abrasion Tester fully complies with ISO 12947, the global benchmark for abrasion resistance, and ASTM D4966, a widely accepted standard in the United States. It also aligns with various national standards to ensure consistent, reliable results no matter your location.

To guarantee precision, every Derui Martindale wear tester comes with calibration and traceability certificates. This means your test data is accurate and can be trusted for R&D, quality control, or regulatory compliance.

A common question we get is about chemical compliance. Our machines are designed to handle a broad range of fabrics and finishes safely and meet the relevant safety standards, making them ideal for testing textiles treated with dyes, coatings, or other chemical finishes.

With Derui, you get a Martindale pilling tester and fabric abrasion testing machine that meets strict quality requirements and supports your commitment to product excellence.

Maintenance, Accessories, and Support from Derui

Keeping your Derui Martindale Abrasion Tester in good shape is easy with our straightforward maintenance guidelines. We recommend routine cleaning after each test and regular lubrication of moving parts to ensure smooth, accurate operation. Following these simple steps can extend the life of your fabric abrasion testing machine and prevent costly downtime.

Derui also offers a range of accessory kits to enhance your testing capabilities. Whether you need extra sample holders, specialized abrasive fabrics, or replacement parts, we’ve got you covered. Our upsell options include advanced digital counters and safety features that can be added to fit your specific testing needs.

We back every Martindale wear tester with a solid warranty and offer comprehensive training to get your team up and running quickly. Plus, Derui provides worldwide customer support, ensuring you have reliable help — whether you’re in a small local lab or a large manufacturing facility anywhere in the U.S.

Pricing, Models, and Purchase Options

Derui offers three main Martindale Abrasion Tester models to fit different testing needs and budgets: Mini, Midi, and Maxi. Each model comes designed for varying test scale and station capacity, making it easy to find the right fit for your lab or production line.

| Model | Stations | Suitable For | Price Range (USD) |

|---|---|---|---|

| Mini | 4-6 | Small labs, spot tests | $2,000 – $3,000 |

| Midi | 9-12 | Medium R&D, quality control | $3,500 – $7,000 |

| Maxi | 16+ | Large production, compliance | $8,000 – $100,00 |

Volume Discounts & Financing Options

- Discounts available for multiple unit orders – ideal for textile manufacturers and testing facilities upgrading equipment fleets.

- Flexible financing plans to ease upfront costs, including lease-to-own programs tailored to U.S. businesses.

Get Started Today

Ready to boost your textile testing accuracy with Derui’s Martindale Wear Tester? Contact us for a personalized quote, customization options, and setup assistance—let’s find the right model for your needs.