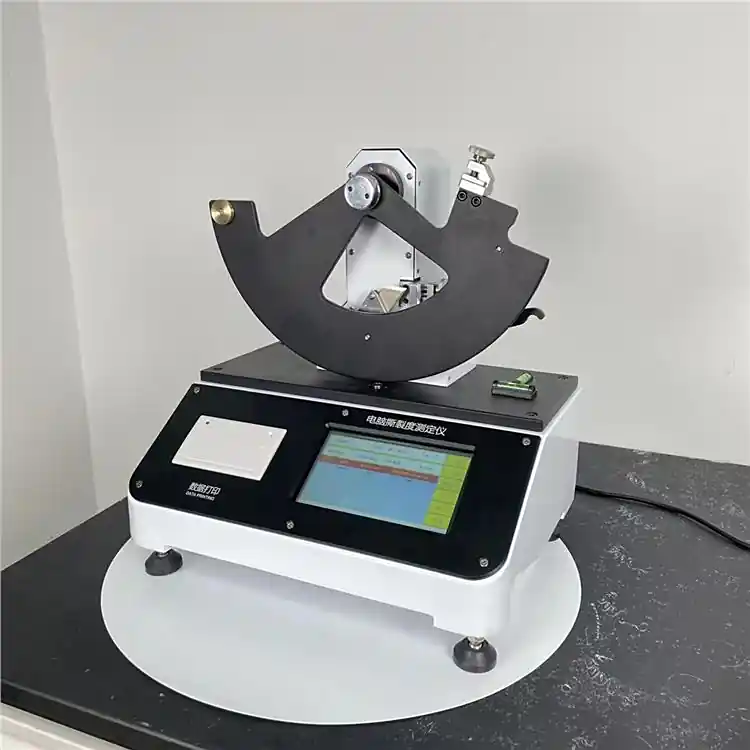

The Martindale Abrasion Tester This test is applicable to the degree of pilling and fuzzing of fabrics. The principle is as follows: A circular sample is rubbed against a fabric of the same material under a given pressure along a Lissajous figure movement trajectory. After reaching a specified number of rotations, the pilling and fuzzing grade of the sample is evaluated. It is also applicable to the abrasion resistance test of fabrics. The principle is as follows: A circular fabric sample is rubbed against a standard abrasive under a certain pressure along a Lissajous curve movement trajectory, causing damage to the sample. The abrasion resistance of the fabric is expressed by the number of abrasion cycles at which the sample is damaged.

Product Features:It can be used for two types of product tests: determination of fabric abrasion resistance and determination of fabric pilling and fuzzing performance.

Scope of application: It can be used to test the abrasion resistance and pilling performance of thin and light fabrics such as cotton, linen, silk, woven fabrics, film materials, knitted fabrics, woolen fabrics, artificial leather, synthetic leather and other textiles. Under a certain pressure, the sample and the specified abrasive are continuously rubbed in opposite directions. The degree of wear and pilling is evaluated by comparing with the standard parameters. It is controlled by a touch screen and equipped with a fully functional programmer, which can pre-program the batch and total count, and set the count of each test head separately. Four speeds including the standard speed can be selected.

Product Features:

1.Modular design for easy loading and unloading of samples.

2.The programmable logic controller (PLC) controls the touch screen. The operation interface is simple, intuitive and easy to operate. Moreover, it offers a dual-language menu option in both Chinese and English.

3.Four, six and nine-station designs are available for selection. It is equipped with two sets of grinding heads, which can simultaneously perform pilling and abrasion resistance tests, significantly improving the testing efficiency.

Configuration:Mainframe, wear-resistant friction head, pilling friction head, 9kpa weight, 12kpa weight.

Test specimens:

- The cutting device, such as a press knife, should be of sufficient size to produce test specimens that can be firmly pressed onto the test specimen carrier. The exact size of the test specimen is determined by the fixture of the test specimen carrier. For the purpose of preventing any edge effects, the test specimen should be circular with a diameter of 44 ± 1 mm. Cut from various sheet materials, avoiding any manufacturing edges by 50 mm.

- Cut an extra test specimen for comparison or reference in cases of fading or wear.

- Place the test specimens in an environment of 20 ± 2°C and 65 ± 2% humidity for 24 hours.

Test Procedure:

- Soak half of the abrasion-resistant specimens and half of the wool felt pieces until the color of both sides of the specimens is significantly darker.

- Place each specimen in the fixture ring with the test surface facing outward.

- If the test specimen weighs 500g/m2, either Test Method A or B can be used. Place foam in each specimen holder to fill the test space of the specimen.

- Clamp the specimens tightly to prevent them from sagging, wrinkling or distorting.

- Place a dry wool felt on half of the abrasion-resistant specimens.

- Place a dry abrasion-resistant specimen on the wool felt with the test surface facing upward.

- Place the weight on the specimen, smooth out the wrinkles, and then remove the weight.

- Repeat steps 6 and 7 on another specimen.

- If necessary, immediately repeat steps 6 to 8 using wet abrasion-resistant specimens and wet wool felt.

- Correctly place the test specimens in the test fixture to ensure normal operation of the test.

- Apply the required force on each test head to ensure that the test specimens and abrasion-resistant specimens are loaded with the specified force values.