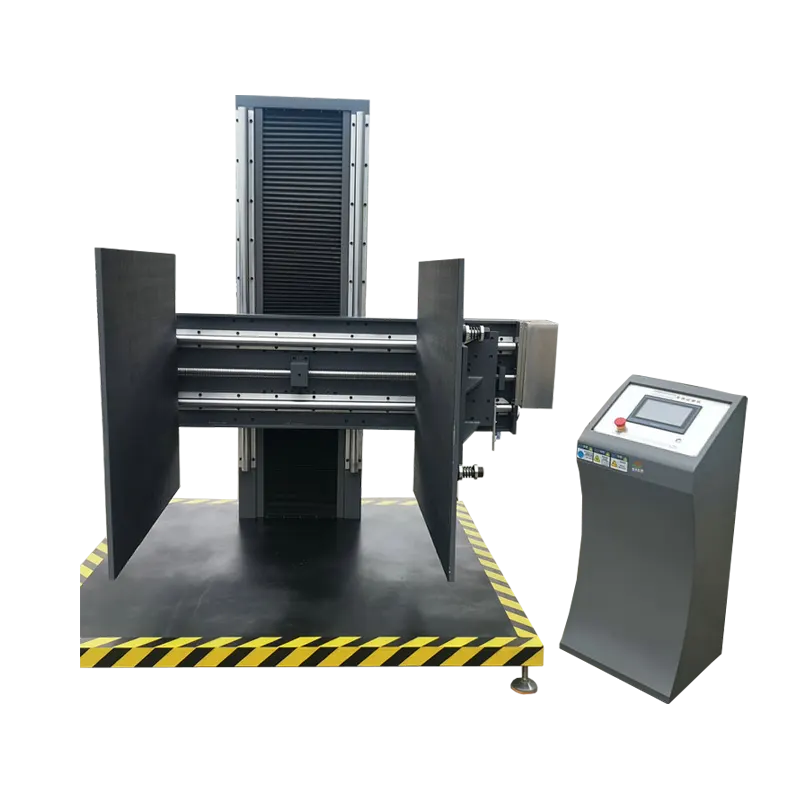

Definition and Application

Designed specifically for testing the durability of office chair seats, it simulates repeated impacts of human sitting postures to evaluate the fatigue performance of materials and the structural stability.

It is suitable for testing chair seat materials (such as sponge, mesh fabric, seat cushion covers), chair frame structures, and overall durability.

Industry Applications

It is widely used in industries such as office furniture, household goods, and sports equipment, meeting international and national standards such as ISO, EN, and GB.

It is applicable to product development, quality inspection, certification, and other scenarios.

Features

It adopts the function of electromagnetic attraction, which is energized and attracted at low position and de-energized and released at high position, to perform free fall impact motion.

2、It can be selected to have single manual impact or multiple continuous automatic impact functions; it can also be selected to have impact or slow loading functions.

3、The height of the crossbeam for installing the impact component can be electrically adjusted. Within the stroke range, it can be self-locked at any position.

4、The sample has a simple clamping structure, which can be operated by one person without any special tools.

5、The sample adopts a "foot cup" structure to maintain horizontal positioning, so that the test sample is not constrained by external forces in the vertical direction.

control system

1、PLC control, touch screen input test parameters and output test results, with power-off memory function to avoid test data loss.

2、Manual impact or automatic impact, as well as impact or static pressure test mode can be switched through the selector switch on the operation panel.

3、The system automatically calculates and displays the loading speed.

4、The system has a power-off memory function to avoid test data loss.

5、The system has a breakpoint detection and automatic shutdown function.

6、A bit counter records the loading times and can be reset at any time; the cumulative reset touch button has a function to prevent accidental operation.

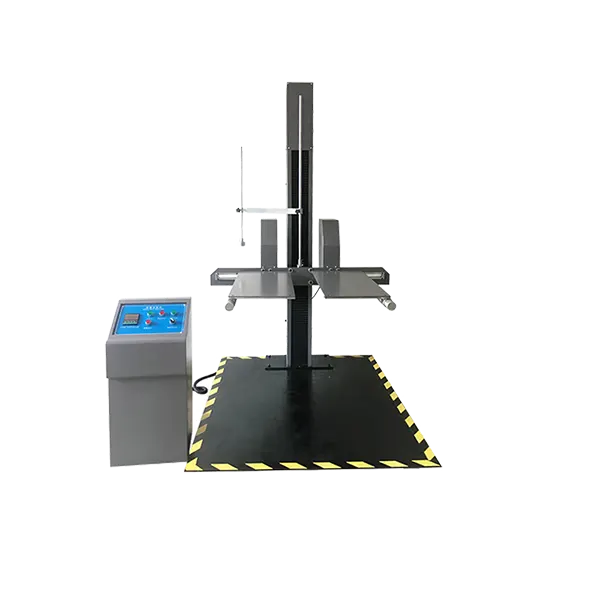

Core components

1、Impact actuator: Pneumatic or electrically driven impact head, simulating the dynamic impact of the human buttocks.

2、Load control system: Adjustable impact force (e.g., 50-500N), precisely simulating the pressure of people with different body weights.

3、Test bench and fixtures: Fixed seats to ensure test repeatability.

4、Data acquisition system: Real-time monitoring of impact force, displacement, speed and other parameters, generating test reports.

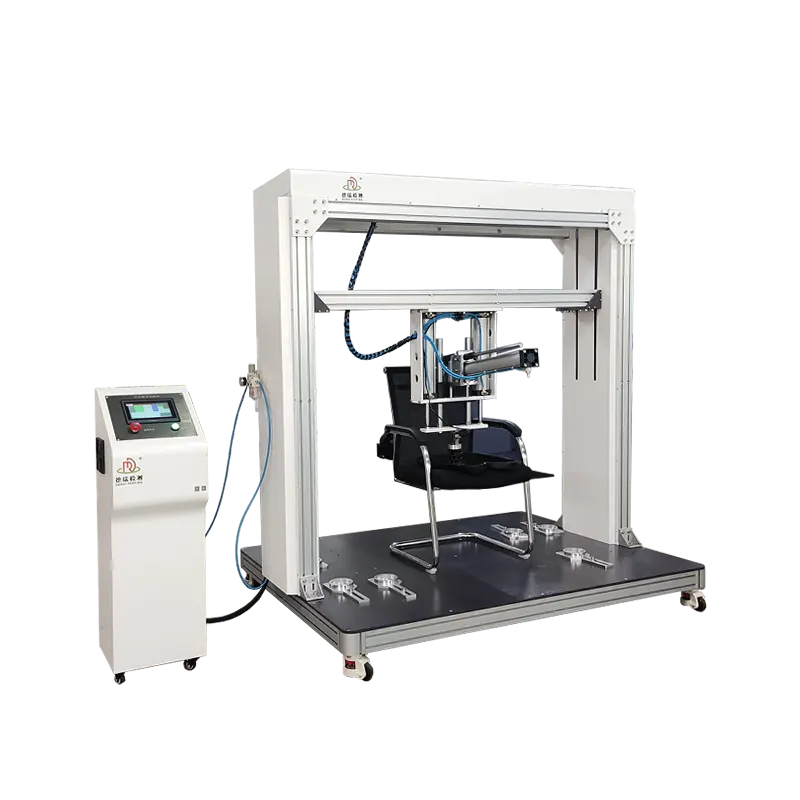

Application scenarios

1、Product Development

Test the durability of the chair seat and optimize the product structure.

2、Quality Inspection

Conduct random sampling inspections in batches to ensure that the products meet industry standards (such as durability ≥ 50,000 impacts).

3、Certification Testing

Support certification testing requirements such as BIFMA, EN 1335, GB/T 1999, etc.

Operation Procedure

1、Installation and Debugging

Fix the equipment, connect the air source/power supply, and calibrate the sensors.

2、Parameter Setting

Input parameters such as impact force, frequency, and number of times, and fix the seat to be tested.

3、Execution of Test

Start the automatic test and monitor the data and status throughout the process.

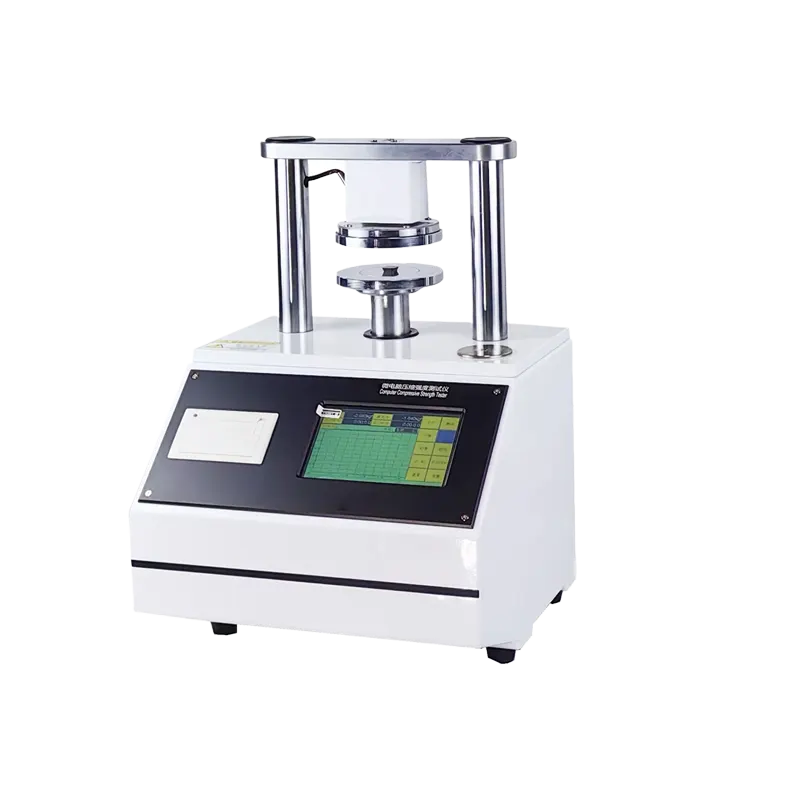

4、Result Analysis

Generate an impact curve report and assess the degree of fatigue damage.

Equipment Maintenance and Care

1、Daily Maintenance

Clean the guide rails, check the sensor connections, and lubricate the moving parts.

2、Regular Calibration

Calibrate the force sensor every six months to ensure test accuracy.

3、Fault Handling

Provide a manual for common problems (such as sensor failure, motor abnormality), along with 24-hour technical support.