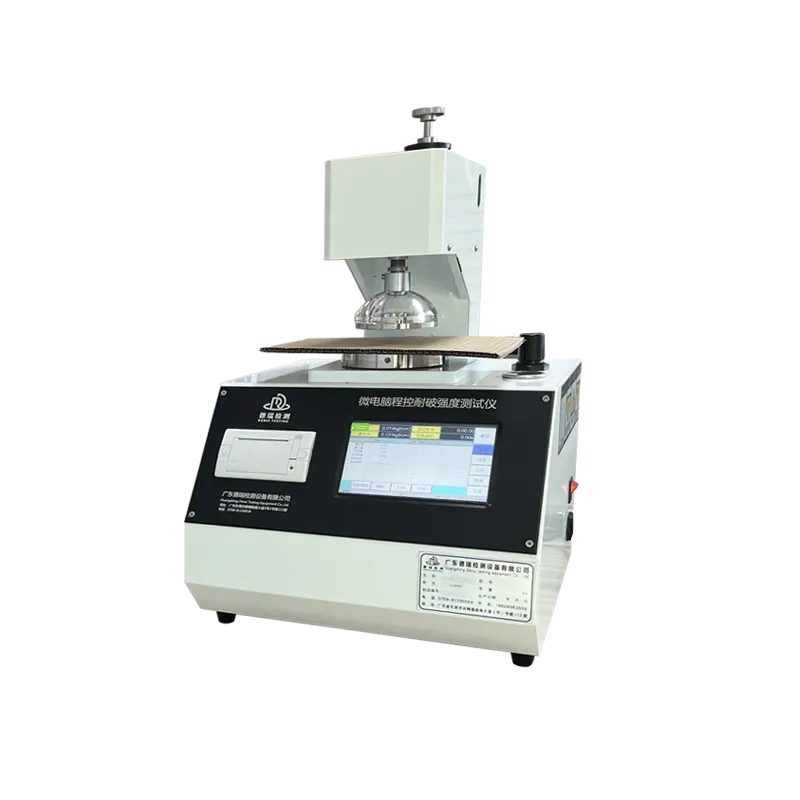

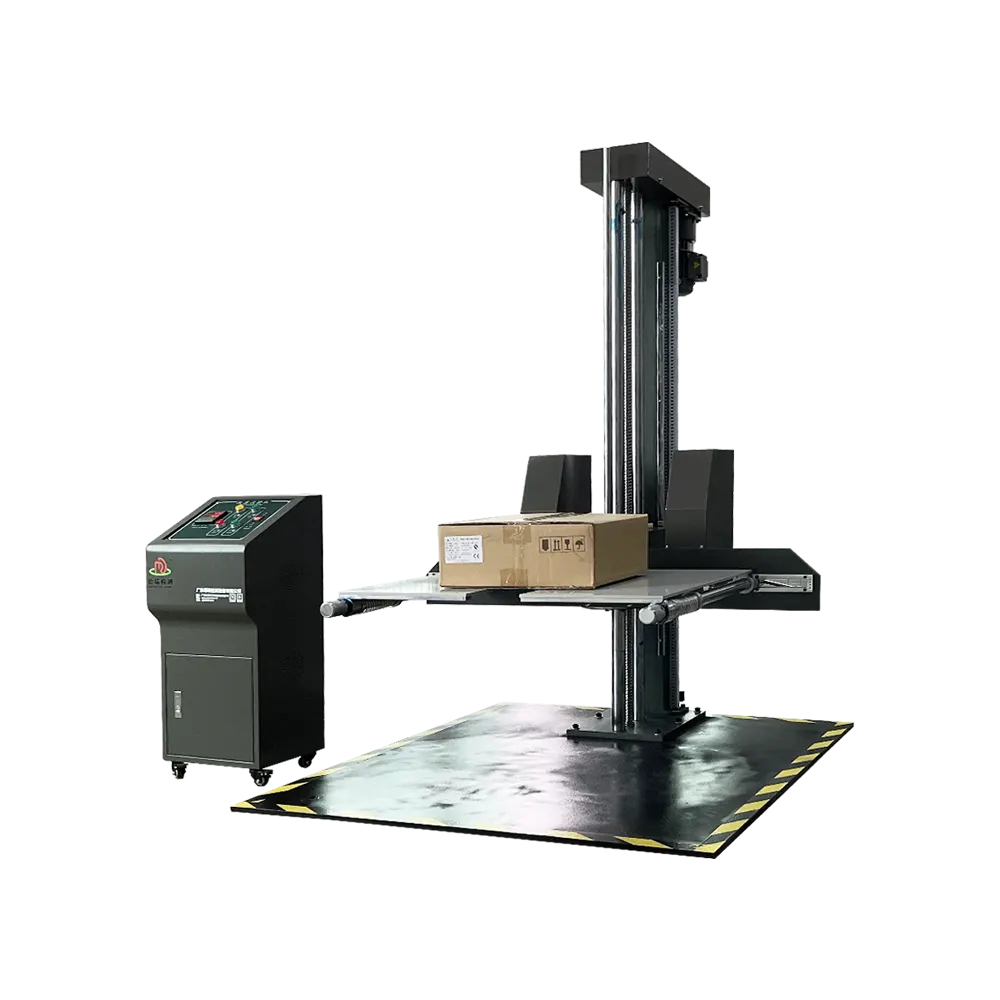

The paper box compression testing machine is a specialized device for testing the compressive strength of paper boxes. It is widely used to assess the compressive resistance, deformation degree, and stacking performance of corrugated boxes, honeycomb board boxes, and other packaging items. Additionally, this equipment can also be utilized to evaluate the compressive performance of various containers such as plastic drums (e.g., edible oil drums, mineral water bottles), paper drums, paper boxes, paper cans, and intermediate bulk containers (IBC).

In the modern packaging field, the box compression tester is an indispensable device, which can ensure that the cartons have sufficient load-bearing capacity during transportation and storage. Whether it is for evaluating the appearance of the product or testing its practical performance in the logistics process, this equipment can accurately measure the compressive strength of the cartons.

Carton Box Compression Tester Design standards

TAPPI-T804,JIS-20212,GB4857.3.4, ASTM-D642, QB/T1048, BS EN ISO 12048, GB/T4857.16,GB/T8167, GB/T8168, GB/T4857.3,GB/T4857.4

Product Characteristics:

Constant Value Test: In compressive testing conditions, a specified pressure is applied to perform a pressure-holding test on the box.

Compression Test: Under compression testing scenarios, pressure is applied until the sample is damaged, allowing for the determination of the box's ultimate compressive strength.

Stacking Test: In stacking test conditions, a predetermined load is applied until the sample is damaged or until the set time has been reached.

Compression Displacement Test: During compression testing, a specific pressure or displacement amount is applied to measure the deformation outcome of the carton after being compressed.

Carton Box Compression Tester Equipment Characteristics

1、The product stands out for its dependable and consistent performance, exceptional measurement accuracy, advanced testing software, and user-friendly, intuitive operation.

2、The machine's construction utilizes high-grade anodized aluminum extrusion panels, combined with precision twin screws and guide columns that feature low resistance and no gaps. This design significantly improves load efficiency and structural stability.

3、The control mechanism employs a digital AC servo system to manage high-frequency response AC motors. This setup guarantees efficient transmission, smooth operation, low noise levels, and speed precision within ±0.2%.

4、A digital interface serves as the primary control unit, enabling users to configure all testing parameters and manage operational statuses effortlessly.