The tester is specifically designed for the tackiness retention test of adhesive tapes in high-temperature environments. It simulates the adhesive tape's ability to maintain adhesion under a specified load in high-temperature conditions and automatically records the duration the tape can hold. This helps to confirm the adhesive tape's adhesive durability. Once the tape drops off the steel plate, the timer automatically retains the test time, which is used to evaluate the adhesive tape's persistence in high-temperature environments.

Working Principle

The constant temperature adhesive tape holding force testing machine mainly adopts the tensile testing method. It fixes the adhesive tape sample between two clamps and tests its holding force by gradually increasing the tensile load. Meanwhile, the equipment is also equipped with a constant temperature device, which can conduct tests under different temperature conditions to simulate the usage of adhesive tape in various environmental conditions.

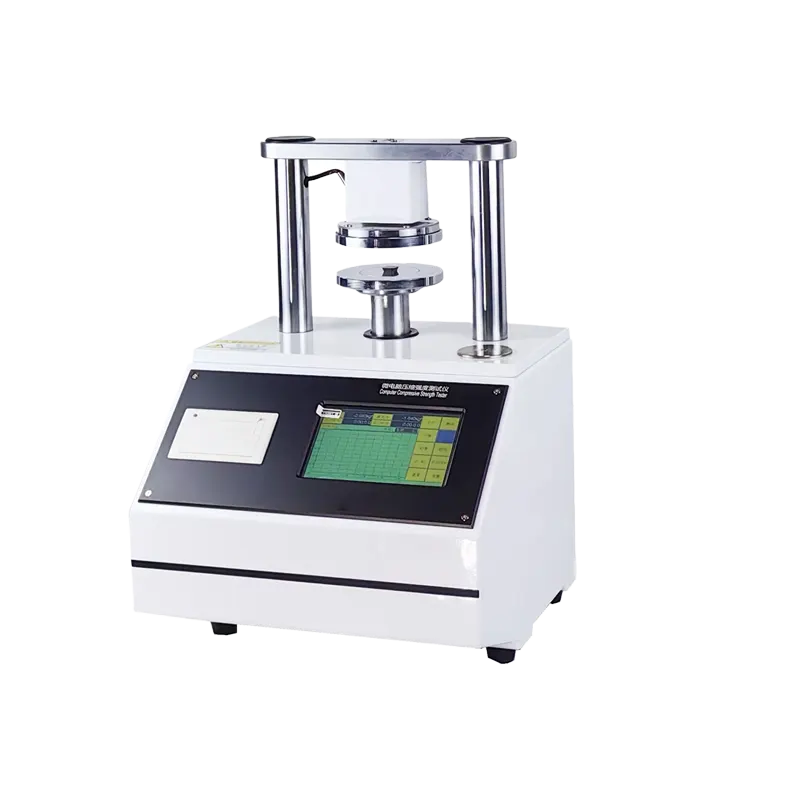

Equipment Structure:The inner tank of the equipment is made of 304 stainless steel, and the outer shell is treated with electrostatic powder coating. The test fixtures and hanging accessories are made of stainless steel to ensure durability in high-temperature environments. The display is an LCD electronic screen that supports touch operation.

Design standards:

- GB 4851 Test method for tack of pressure-sensitive adhesive tapes.

- Test methods for pressure-sensitive adhesive tapes and pressure-sensitive adhesive sheets - JIS Z0237.

- Test Method for Shear Adhesion of Pressure-Sensitive Tapes - ASTM D3654

The equipment usually consists of the following structural parts:

Test steel plate: Mainly used for attaching tape samples, usually made of stainless steel.

Counterweight weights: used to apply a constant load, typically 1kg or a specified weight.

Timing system: Records the adhesive time of the tape or the sliding distance.

Operating method:

1.Remove the outermost 3 to 5 circles of adhesive tape from the adhesive tape roll. Then, unwind the sample roll at a rate of approximately 300 mm/min (for sheet samples, remove the release liner at the same rate). At intervals of about 200 mm, cut a sample of 25 mm in width and approximately 100 mm in length from the middle of the adhesive tape. Unless otherwise specified, the number of samples in each group should be no less than three.

2.Use a cleaning agent to wipe the test plate and loading plate with a wiping material, then carefully dry them with a clean gauze. Repeat this process three times or more until the working surface of the plate is visually clean. After cleaning, do not touch the working surface of the plate with hands or other objects.

3.Under conditions of temperature 23℃ ± 2℃ and relative humidity 65% ± 5%, the sample shall be adhered parallel to the longitudinal direction of the board at the middle of the adjacent test board and loading board as per the dimensions specified in Figure 2. A roller shall be used to roll over the sample at a speed of approximately 300 mm/min. During the rolling process, only the force generated by the mass of the roller shall be applied to the sample. The number of rolling passes can be specified according to the specific product conditions. If not specified, three reciprocating passes shall be made.

4.After the sample is pasted on the plate, it should be placed under conditions of 23℃ ± 2℃ and a relative humidity of 65% ± 5% for 20 minutes. Then, the test plate should be vertically fixed on the test frame of the instrument, and the loading plate and the weights should be gently connected with pins.

5.Place the instrument horizontally. Turn on the power switch, the heating switch and the fan switch in sequence. Press the protruding part on the timer to reset the time. The instrument will automatically start up according to the preset temperature and keep running until the temperature inside the test chamber stabilizes at the set value.

6.After the specified time has elapsed, remove the load. Use a magnifying glass with a scale to measure the displacement of the specimen's downward movement, accurate to 0.1mm; or record the time when the specimen falls off the test board. If the time is greater than or equal to 1 hour, record it in minutes; if it is less than 1 hour, record it in seconds.