What is a Single Wing Drop Test Machine

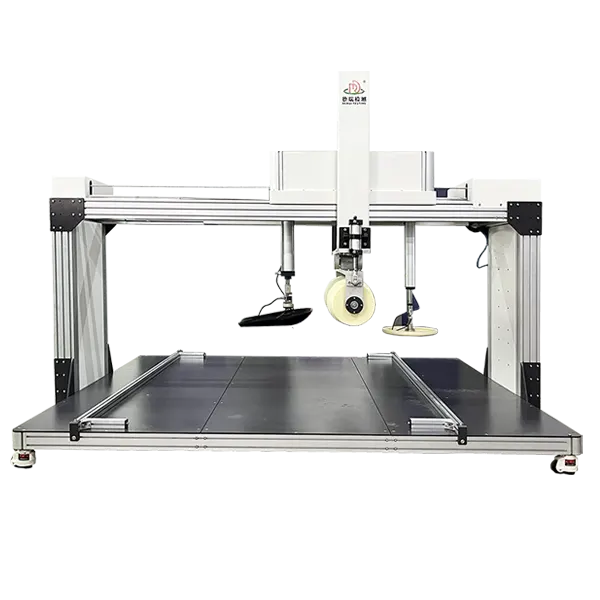

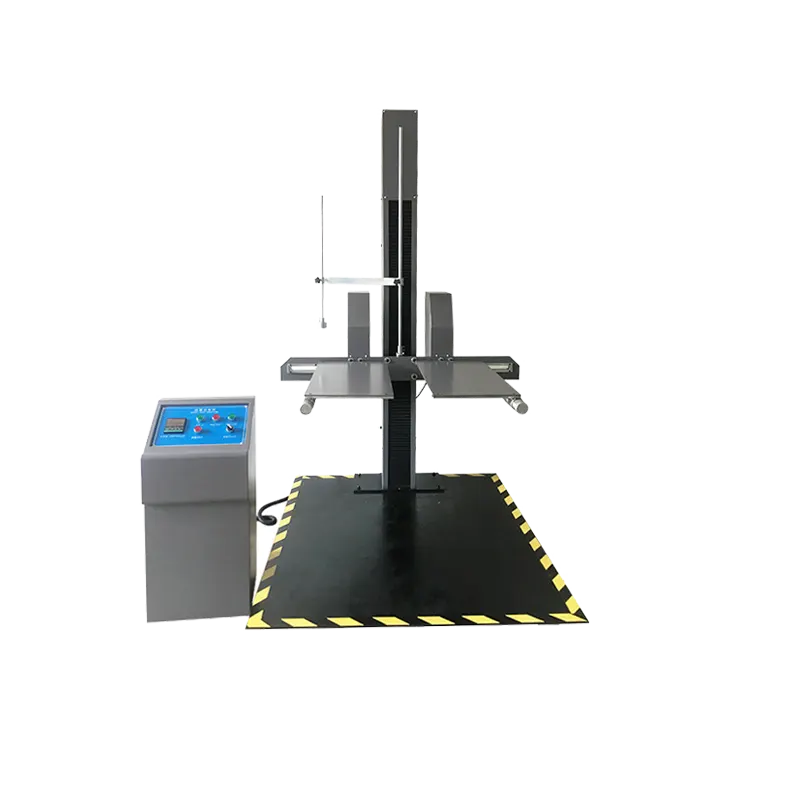

A Single Wing Drop Test Machine is specialized packaging drop test equipment designed to simulate the impact a product undergoes during shipping and handling. It features a single-arm wing mechanism that securely holds the package and releases it to fall freely from a predetermined height onto a test surface. This controlled drop mimics real-world conditions to evaluate packaging durability and product protection.

Unlike double wing or multi wing drop testers, which use two or more release arms for larger or heavier packages, the single wing design offers simplicity, space efficiency, and reliable operation. It is ideal for testing small to medium-sized boxes where precise, repeatable drops are required.

The basic structure of a Single Wing Drop Test Machine includes:

- A rigid frame supporting the drop platform

- An adjustable height system for programming drop heights

- The single wing arm that locks and releases the package

- A test surface that simulates common shipping impacts

The working principle is straightforward: once the package is secured on the wing arm at the desired height, the arm pivots or releases to allow a free-fall drop. This ensures consistent testing under ISTA or ASTM drop test standards, helping manufacturers enhance packaging quality control.

Importance of Drop Testing in Packaging

Packaging faces a lot of rough treatment during shipping and handling. Boxes can get dropped, bumped, or dropped from different angles, causing damage not just to the packaging but often to the product inside. Common issues include crushed corners, torn packaging, broken seals, and internal product damage.

Drop testing plays a key role in spotting weak points early. By simulating real-world drops, it helps prevent costly product failures and returns. This testing makes sure packages hold up well enough to protect products through the entire shipping process.

There are strict industry rules around drop testing. Standards like ISTA (International Safe Transit Association) and ASTM (American Society for Testing and Materials) set guidelines for package drop tests, ensuring consistency and reliability across the supply chain. Meeting these standards is often required for product certification or customer acceptance.

Benefits of thorough drop testing for manufacturers and supply chains include:

- Reduced product damage and returns

- Lower shipping and handling costs

- Improved customer satisfaction

- Better packaging design and material choices

- Compliance with ISTA and ASTM drop test standards

Overall, drop testing is essential for anyone serious about packaging quality control testing and ensuring their products arrive safe and sound.

Key Features and Components of a Single Wing Drop Test Machine

A single wing drop test machine centers on a simple yet effective drop platform with adjustable height settings. This lets you set the drop distance according to packaging size and test standards like ISTA or ASTM.

The single arm wing design is a key highlight. It swings out to release the package at the right angle, offering several advantages:

- Simplicity – fewer moving parts mean less maintenance

- Reliability – consistent drop performance without complex calibration

- Space saving – smaller footprint compared to double or multi-wing testers

Safety is a priority. Most units have:

- Emergency stop buttons

- Safety shields around the drop zone

- Load sensors to prevent accidental drops

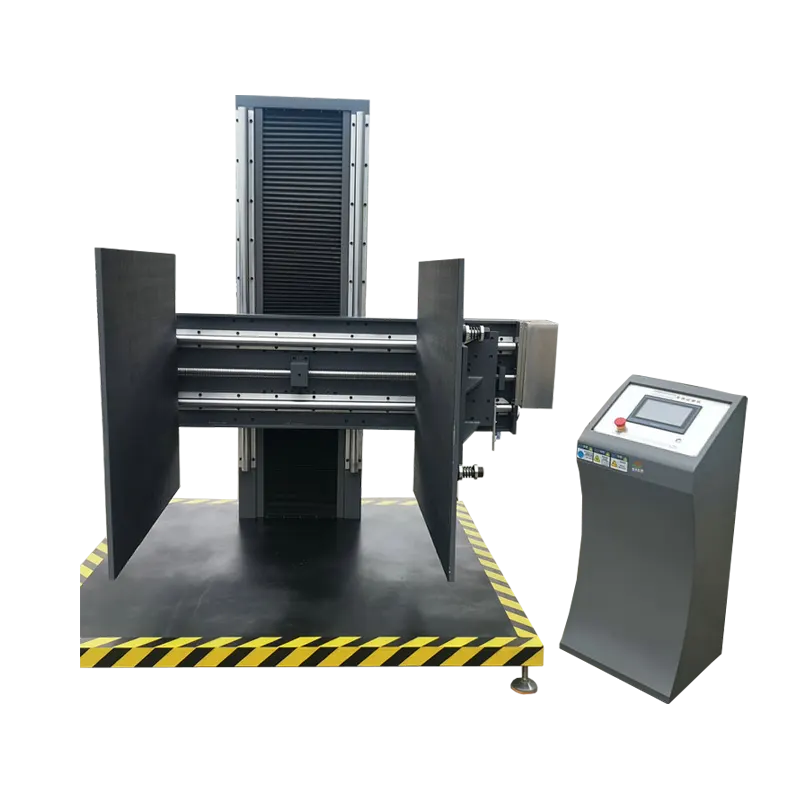

Control options vary:

- Manual controls offer straightforward operation for smaller testing needs

- Automated controls include programmable drop sequences and repeat testing for high-volume labs or production lines

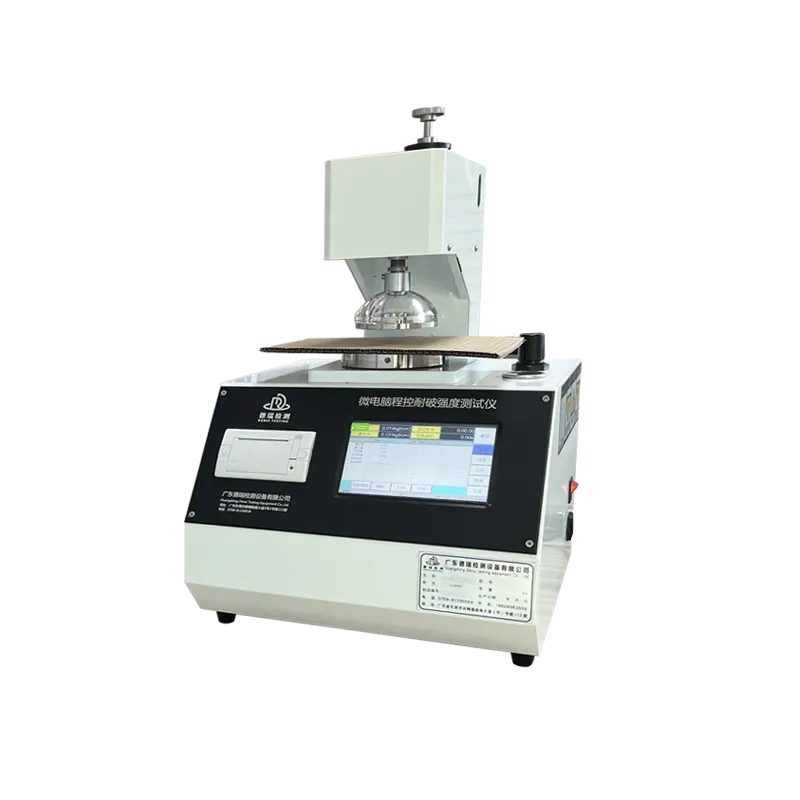

Data collection is critical for packaging quality control testing. Many machines support:

- Impact force measurement

- Drop count logging

- Integration with software for detailed analysis

Dimensions and capacity vary, but single wing drop testers typically handle packages from a few inches up to several feet, compatible with cardboard, plastic, and composite materials.

| Feature | Description | Benefit |

|---|---|---|

| Drop Platform | Adjustable height platform | Customizable drop distance |

| Single Wing Arm | Swinging release mechanism | Simple, reliable, space-saving |

| Safety Features | Emergency stops, shields, sensors | Operator protection |

| Controls | Manual or automated | Flexible operation modes |

| Data Collection | Impact force and drop logs | Accurate test results |

| Package Capacity | Supports small to large packages | Versatile testing range |

How Single Wing Drop Test Machines Operate

Using a single wing drop test machine is straightforward and efficient, making it a popular choice for packaging quality control testing. Here’s how it works step by step:

- Prepare the Package: Place the box or package securely on the drop platform. Make sure it’s set according to the required drop orientation—face, edge, or corner.

- Set Drop Height: Adjust the drop height using the machine’s height controls. This is key to meeting test standards like ISTA or ASTM and matching the actual shipping conditions your package will face.

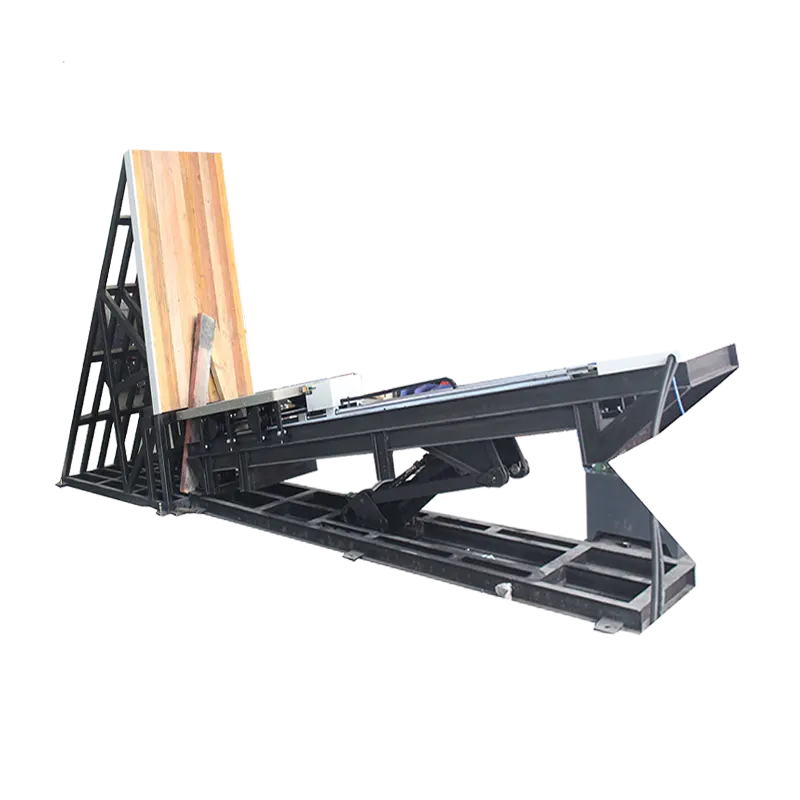

- Choose Drop Type: Select the type of drop test you want to run. Common options include:

- Free Fall Drop: The package drops straight down with no restraints.

- Controlled Angle Drop: The package is dropped while rotating to simulate real-world impacts.

- Corner Drop and Edge Drop: Focuses on the most vulnerable spots of the package.

- Start the Test: Activate the single arm wing mechanism which quickly releases the package for the drop. The single wing design ensures reliable, smooth release and consistent drop performance.

- Record and Analyze Impact: Use the machine’s data collection system (if available) to measure impact forces and record package responses. This helps assess if the packaging can survive actual shipping and handling stresses.

Setting parameters depends on your packaging type and test needs:

- Heavy or fragile items may need lower drop heights but more test repetitions.

- Durable packaging can be tested at higher heights or with multiple drop types.

- Follow industry standards relevant to your product and shipping route for precise settings.

Overall, the single wing drop tester provides an easy, accurate way to simulate real shipping impacts and improve packaging durability.

Applications of Single Wing Drop Test Machines in Packaging Industry

Single wing drop test machines work well with a variety of packaging materials like cardboard, plastic, and composite packaging. This versatility makes them a solid choice for testing everything from lightweight boxes to heavier, more complex packs.

Several industries benefit from using these machines to ensure their packaging can handle real-world shipping stress:

- Electronics: Safeguards delicate devices like phones and computers from damage during transit.

- Food and Beverage: Ensures fragile bottles and containers arrive intact without leaks or breaks.

- Consumer Goods: Validates packaging durability for items ranging from household products to cosmetics.

- Pharmaceuticals: Protects sensitive medical products that require careful handling and strict compliance.

For example, a U.S.-based snack company used a single wing drop test machine to simulate their shipping conditions. The test helped them identify weak points in their packaging, leading to a redesign that cut product breakage by 25%. Similarly, an electronics retailer reduced returns due to shipping damage by testing multiple drop angles on their new packaging design before mass distribution.

These real-world results highlight how using a single wing drop test machine supports better packaging design and improves overall product safety across industries.

How to Choose the Right Single Wing Drop Test Machine

Picking the best single wing drop test machine comes down to understanding your testing needs and budget. Here are the main factors to keep in mind:

Key Factors to Consider

| Factor | What to Look For |

|---|---|

| Drop Height Range | Make sure it covers the highest and lowest drops your packaging needs, usually up to 2 meters. |

| Size and Capacity | Match the platform size with the largest package you test to avoid limitations. |

| Automation Level | Manual controls are budget-friendly; automated systems save time and improve repeatability. |

| Budget | Balance between features you need and your price range to get the best value without overspending. |

| Brand Reliability | Choose brands with solid reputations, like Derui, known for quality and dependable machines. |

| After Sales Service | Access to quick support, spare parts, and technical help is crucial for smooth operations. |

| Calibration Support | Regular calibration ensures accurate test results—check if the manufacturer offers easy calibration options. |

Comparing Single Wing With Other Models

- Single Wing Machines: Simpler, space-saving, reliable—great for most packaging drop tests.

- Double Wing Machines: Handle larger or heavier packages but take up more space and cost more.

- Multi Wing Machines: Best for very high-volume testing with complex drop scenarios but require bigger budgets.

Why Choose Derui Single Wing Drop Test Machines

- Quality Build: Durable materials designed for long-term use.

- Precision Controls: Manual and automated options for flexible testing.

- Accurate Data: Integrated impact measurement and data logging.

- Customer Support: Fast, knowledgeable service and calibration assistance.

- Value for Money: Competitive pricing without cutting corners on features.

Choosing the right single wing drop tester means balancing your testing needs with machine features, budget, and support. Derui’s machines offer a solid mix of all these, making them a top pick in the U.S. packaging industry.

Maintenance and Calibration Tips for Longevity and Accuracy

To keep your single wing drop test machine working smoothly and delivering accurate results, regular maintenance and calibration are essential.

Regular Inspection Routines

- Check moving parts like the drop arm and platform for wear or damage.

- Inspect control panels and safety features to ensure everything operates correctly.

- Clean the machine to prevent dust and debris buildup that could affect performance.

- Lubricate mechanical components following the manufacturer’s guidelines to avoid friction.

Calibration Frequency and Procedure

- Calibrate at least once every 6 months, or more often if your testing is frequent and critical.

- Use certified calibration tools to verify drop height accuracy, timing, and impact measurement.

- Follow a step-by-step calibration process as outlined by the manufacturer or lab standards.

- Keep detailed records of each calibration to track performance over time.

Troubleshooting Common Issues

- Inconsistent drop height: Check for sensor misalignment or mechanical blockages.

- Control panel unresponsive: Inspect wiring for damage and reset the system if needed.

- Unexpected machine stops: Review safety switches and emergency stops to ensure proper function.

- Data recording errors: Verify software settings and data connections.

With proper upkeep, your packaging drop test equipment will stay reliable, ensuring your drop tests meet ISTA and ASTM standards and protect your products throughout the shipping process.