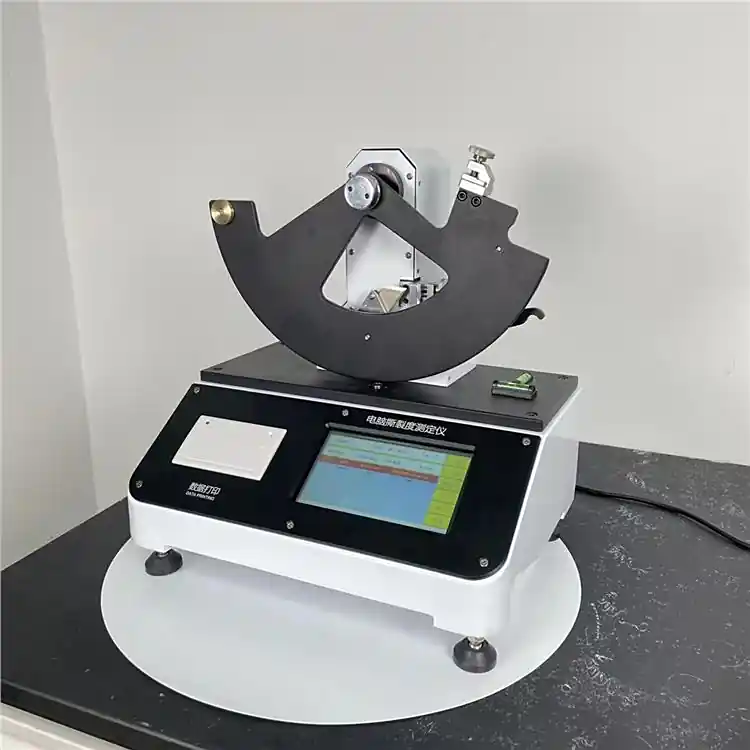

If you’re involved in the rubber industry, you already know how critical precise testing is for ensuring quality and performance. Enter the Rubber Rotorless Rheometer — a game-changing instrument that’s reshaping how we analyze rubber compounds and their curing behaviors. Unlike traditional rotor-type rheometers, the rotorless design offers unmatched sensitivity, better accuracy, and simpler operation, making it an essential tool for anyone serious about rubber testing and production. Ready to unlock the full potential of your rubber testing process? Let’s dive into everything you need to know about this innovative technology and why it’s becoming the gold standard in the industry.

What is a Rubber Rotorless Rheometer

A rubber rotorless rheometer is a specialized instrument used to test the rheological properties and vulcanization behavior of rubber compounds. Unlike traditional rotor rheometers that use a rotating spindle, rotorless rheometers measure rubber’s cure characteristics without any rotational movement. This design improves sensitivity and accuracy in detecting changes in the material’s viscoelastic properties during curing.

Rotor Versus Rotorless Rheometers Key Differences

| Feature | Rotor Rheometer | Rotorless Rheometer |

|---|---|---|

| Movement | Rotating spindle | Stationary sample, no rotation |

| Mechanical friction | Present, can affect data | Minimal friction, higher accuracy |

| Sensitivity | Moderate | High, detects subtle changes |

| Maintenance | Higher due to moving parts | Lower maintenance |

| Sample handling | More complex | Easier and quicker |

Core Principles of Operation

Rotorless rheometers work by subjecting the rubber sample to controlled temperature and oscillating strain without rotating parts. Torque sensors measure the resistance from the polymer as it cures, reflecting changes in viscosity and modulus. This non-rotational approach allows for precise monitoring of curing kinetics like scorch time and cure rate.

Types of Rotorless Rheometers for Rubber Testing

- Oscillating Disk Rheometers: Use an oscillatory motion to measure torque changes without rotation.

- Dynamic Mechanical Analyzers (DMA): Assess viscoelastic properties under controlled temperature and strain.

- Rubber Curing Process Analyzers: Specialized rotorless instruments focused on vulcanization curve tracking.

Each type fits different testing needs, whether for detailed research or routine quality control.

Technology and Working Mechanism

A Rubber Rotorless Rheometer measures rubber’s viscosity and cure characteristics without using a traditional rotor. Instead, it relies on applying oscillating strain to the rubber sample while keeping it fixed in place. This non-rotational method enhances the instrument’s sensitivity, giving more precise readings of how the rubber behaves under heat and pressure.

Temperature control is critical in the process. The rheometer carefully heats the rubber sample to simulate curing conditions, allowing it to track changes in viscosity and stiffness as the material vulcanizes. Torque sensing measures the resistance of the rubber to deformation, providing real-time data on the curing process.

Strain measurements help analyze how the rubber’s elastic and viscous properties evolve during testing. Unlike rotor rheometers, the rotorless design eliminates friction and mechanical losses, leading to cleaner, more accurate data.

Typical test parameters you can track include:

- Scorch time – when the rubber starts to cure

- Cure rate – how quickly the rubber crosslinks

- Modulus – measures stiffness changes through the cure

- Viscous and elastic moduli – show rubber’s flow and deformation behavior

This technology gives you detailed insight into the rubber’s rheological properties, making it essential for fine-tuning formulations and controlling quality in manufacturing.

Advantages of Rubber Rotorless Rheometers

Rubber rotorless rheometers offer several practical benefits, especially for U.S. manufacturers focused on precise rubber vulcanization testing instruments. Here’s why they stand out:

Key Advantages

- No Rotor Friction

- Eliminates mechanical noise and friction that can skew data.

- Provides cleaner, more accurate measurements of rheological properties of rubber.

- Enhanced Durability and Lower Maintenance

- Fewer moving parts reduce wear and tear.

- Cuts down on downtime and maintenance costs.

- Easier Cleaning and Sample Handling

- Open design simplifies sample placement and cleaning.

- Saves time during back-to-back testing.

- Wide Compatibility with Rubber Compounds

- Works well with diverse formulations, from natural rubbers to synthetic blends.

- Ideal for testing various polymer rheology and cure characteristics.

- Improved Consistency for Quality Control

- Reliable readings support tighter process control.

- Speeds up R&D cycles with fast, repeatable results.

Benefits at a Glance

| Advantage | Benefit |

|---|---|

| No rotor friction | Accurate, noise-free data |

| Reduced mechanical complexity | Longer instrument life |

| Simple cleaning & handling | Faster lab throughput |

| Broad compound compatibility | Versatile testing applications |

| Consistent, repeatable results | Better QC and faster development |

These benefits make rotorless rheometers a smart choice for companies looking to enhance rubber compound quality and optimize the rubber curing process analyzer setup.

Applications of Rotorless Rheometers in the Rubber Industry

Rotorless rheometers play a crucial role in testing rubber raw materials and compounds, helping manufacturers understand how different formulations will perform. They are essential for monitoring vulcanization processes by tracking cure kinetics like scorch time and cure rate, which directly affect product quality.

These instruments ensure rubber products meet industry standards such as ISO and ASTM, giving confidence in compliance and consistency. You’ll find rotorless rheometers widely used in automotive tire manufacturing, where precise control over rubber curing impacts safety and durability. They’re also important in medical devices, consumer goods, and various rubber product lines, providing reliable data that supports better product performance.

Many production facilities integrate rotorless rheometers directly into their lines for real-time quality assessment. This real-time monitoring allows for quick adjustments, reducing waste and speeding up research and development cycles. Whether you’re dealing with tires, seals, or molded rubber parts, rotorless rheometers are key tools to maintain quality and optimize rubber curing processes.

How to Choose the Right Rotorless Rheometer Key Considerations

Selecting the right rubber rotorless rheometer depends on a few essential factors that fit your testing needs and budget. Here’s what to keep in mind:

Key Factors to Evaluate

| Factor | What to Check |

|---|---|

| Sample Size | Can it handle the volume and type of rubber you test regularly? |

| Test Accuracy | Look for sensitive torque measurement and precise temperature control. |

| Ease of Operation | User-friendly interface and simple sample loading save time. |

| Data Analysis | Good software with clear vulcanization curve interpretation is a must. |

| Brand Reputation | Choose a trusted brand with proven reliability, like Derui. |

| After-Sales Service | Fast, helpful support and training help avoid downtime. |

| Price vs Performance | Balance your budget with quality and durability for long-term value. |

| Software Compatibility | Should integrate with modern data management systems used in your lab or production. |

Why Consider Derui

Derui stands out by offering advanced rotorless rheometers built for accuracy and durability, backed by solid customer support. Their instruments support detailed rheological properties testing, including scorch time, cure rate, and modulus tracking, essential for rubber compound quality control and R&D.

Choosing a device that matches your sample types and workflow ensures smoother testing, quicker insights, and reliable data – critical for staying competitive in the U.S. rubber industry.

Interpreting Test Results What the Data Means for Your Rubber Compound

When you run tests with a rubber rotorless rheometer, the data you get is your roadmap to understanding your rubber compound’s behavior. Here’s what to look for and how to use it:

Key Data Points to Understand

- Torque curves: These show how your compound resists deformation over time. A rising torque means the rubber is curing and getting stiffer.

- Scorch time: This tells you when the rubber starts to cure—crucial for avoiding premature vulcanization during processing.

- Cure time: The total time needed for the compound to reach full vulcanization, helping you optimize cycle times.

- Modulus values (elastic and viscous): These indicate the rubber’s stiffness and flow properties, key to predicting performance.

Using Data for Better Formulations and Curing

- Adjust your formula if scorch time is too short or long—you want a balance to prevent early curing or poor final properties.

- Monitor cure time and rate to fine-tune vulcanization schedules—this improves product consistency and reduces waste.

- Use modulus trends to select fillers or additives for the desired flexibility and strength.

Typical Test Result Examples

- A sharp increase in torque after a long scorch time might indicate a slow curing compound or missing accelerators.

- Flat torque curves could mean incomplete curing or a problem with the sample.

- Early scorch time combined with quick cure rate often needs adjusting to avoid off-spec parts.

Troubleshooting Common Issues

- Unusual torque curve shapes: Could mean air bubbles or inconsistent sample thickness.

- Irregular scorch or cure times: May point to temperature control issues or contamination.

- Unexpected modulus values: Check for material mix-up or improper sample prep.

Reading these results correctly lets you make smarter decisions in quality control and R&D, ensuring your rubber products meet exact standards without costly delays.

Maintenance and Best Practices for Using Rubber Rotorless Rheometers

Keeping your rubber rotorless rheometer in top shape is key to reliable results and smooth operations. Here’s what you need to know for maintenance and best use:

Routine Calibration and Maintenance

- Calibrate regularly to ensure accuracy in torque and temperature readings. Follow the manufacturer’s schedule or check at least every six months.

- Clean the instrument thoroughly after each test to avoid residue build-up that can affect performance. Use recommended solvents or cleaning tools.

- Inspect sensors and heating elements for wear or damage and replace parts as needed to avoid downtime.

Sample Preparation for Consistent Results

- Always prepare rubber samples with uniform size and weight to get reproducible data.

- Avoid air bubbles or inhomogeneous mixing as these affect rheological readings.

- Condition samples properly, maintaining consistent temperature and humidity before testing.

Troubleshooting Common Issues

- Inconsistent torque readings? Check for proper sample placement and confirm sensor calibration.

- Temperature fluctuations? Verify heating system function and sensor accuracy.

- Unexpected noise or mechanical resistance? Although rotorless designs cut down friction, check for loose fittings or external vibrations.

Training and Technical Support from Derui

- Derui offers comprehensive training to help your team operate the rotorless rheometer correctly.

- Access to detailed manuals and remote support lets you solve problems fast.

- Regular software updates ensure your device runs with the latest features for data analysis and instrument control.

Following these best practices helps maintain your rotorless rheometer’s precision and extends its lifespan, supporting high-quality rubber testing for your needs.

Why Choose Derui for Your Rubber Testing Needs

Derui stands out in the US market with a comprehensive range of rubber rotorless rheometers designed for accuracy and durability. Their lineup covers various testing needs—from basic lab analysis to advanced rubber curing process analyzers—making it easy to find the right fit for your operation.

Unique Technology Advantages

- Rotorless design ensures no friction, improving data precision.

- Advanced temperature control and torque sensing for reliable cure characteristic measurements.

- High sensitivity lets you detect subtle changes in rubber compound quality.

- Easy-to-use software integrates smoothly with modern data management systems.

- Built for low maintenance and longer service life, minimizing downtime.

Customer Support and Training

Derui offers:

- Nationwide service network with quick response times.

- Online and on-site training to help your team get the most from the equipment.

- Regular software updates and troubleshooting assistance.

Proven Effectiveness

| Feature | Benefit | Example Use Case |

|---|---|---|

| Rotorless rheometer technology | Increased data accuracy | Improving tire compound uniformity |

| User-friendly interface | Faster test setup and operation | Streamlining R&D and QC cycles |

| Technical support availability | Reduced downtime | Keeping production lines running smoothly |

Customers across automotive, medical, and consumer goods industries have trusted Derui’s instruments to deliver consistent, actionable results that enhance quality control and boost productivity.