Understanding Zero Drop Testing for Paper Packaging

Zero drop testing is a crucial process designed to simulate the exact moment a package experiences a sudden fall from a stationary position. For paper packaging, this means replicating real-world impacts that happen during handling, shipping, and unloading. Unlike traditional drop tests that involve some fall height, zero drop testing drops the carton from zero distance, precisely measuring how packages absorb and withstand immediate impacts.

Common packaging failures include crushed corners, torn edges, and compromised seals—problems that often occur even with minimal drops. Zero drop testing helps identify weak points in paper packaging by replicating these near-immediate falls. This testing reveals how well your cartons and corrugated boxes can maintain integrity under sudden shocks, preventing costly damages and returns.

By applying zero drop testing, manufacturers can fine-tune their packaging designs, improving durability and reducing failure rates during transport. This process not only safeguards products but also enhances customer satisfaction by ensuring packages arrive intact every time.

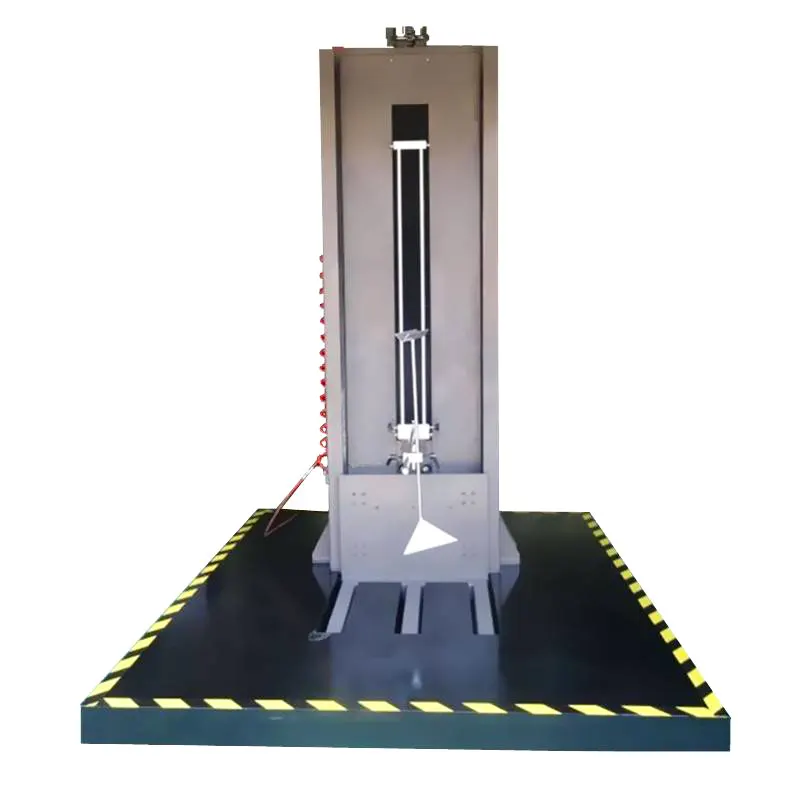

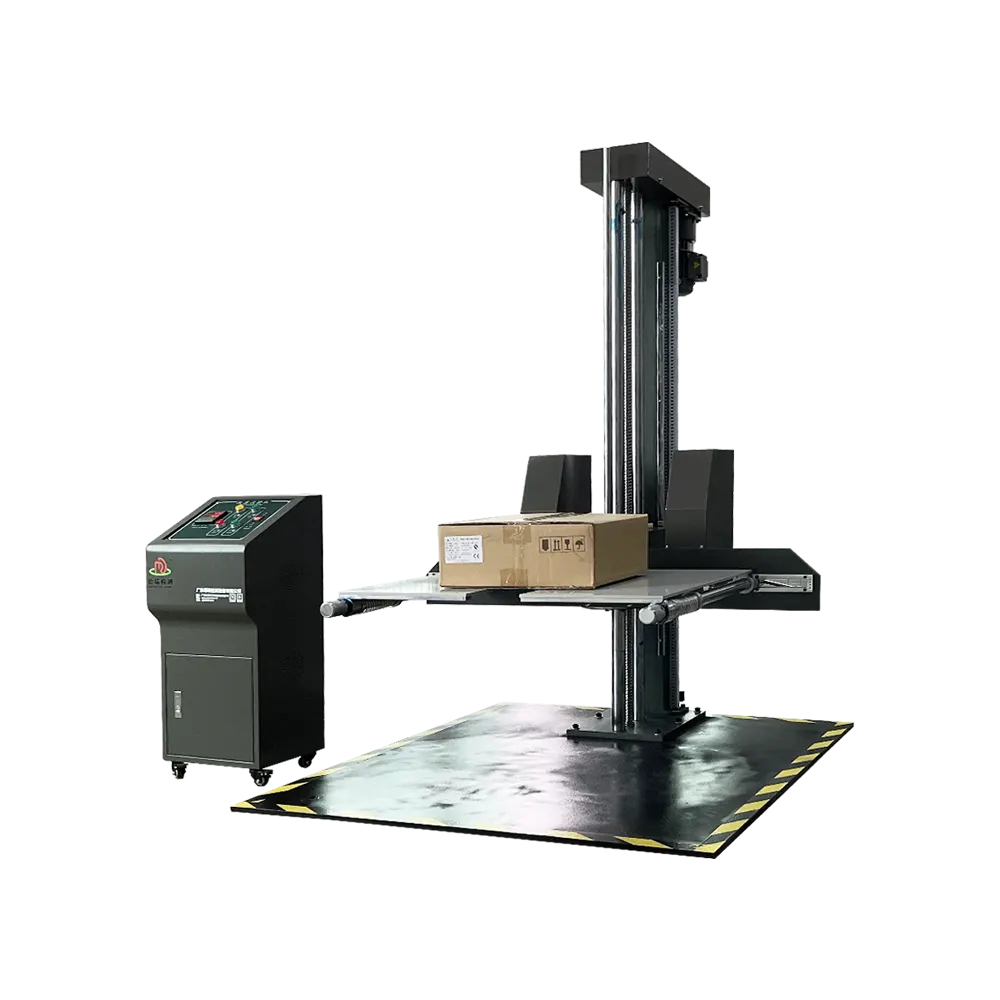

Key Features of the Derui Zero Drop Tester: Innovations from Derui

The Derui Zero Drop Tester stands out in the U.S. market for paper packaging durability testing. Designed to meet real-world needs, it combines smart features with user-friendly operation. Here’s what makes it a top choice:

| Feature | Benefit |

|---|---|

| Zero Distance Drop System | Simulates true free fall without height gaps, ensuring accurate test results for cartons and paper packaging. |

| PLC-Controlled Operation | Offers precise control and repeatability, making tests consistent and reliable every time. |

| Heavy-Duty Frame | Durable enough for frequent use with large paper cartons and corrugated boxes. |

| Multi-Drop Modes | Includes edge, corner, and flat drop testing to cover all possible impact scenarios. |

| User-Friendly Interface | Simple touchscreen controls with easy setup save time in the lab or production line. |

| Compliance Ready | Built to meet ISTA 3A, ASTM D5276, and other drop test standards used in the U.S. packaging industry. |

| Compact Design | Fits well into limited lab spaces without sacrificing performance or capacity. |

Derui’s innovations, like the zero height dropper and precise impact control, ensure your paper packaging passes tough shipping conditions with flying colors. You get reliable results fast, helping you reduce damage claims and boost customer satisfaction.

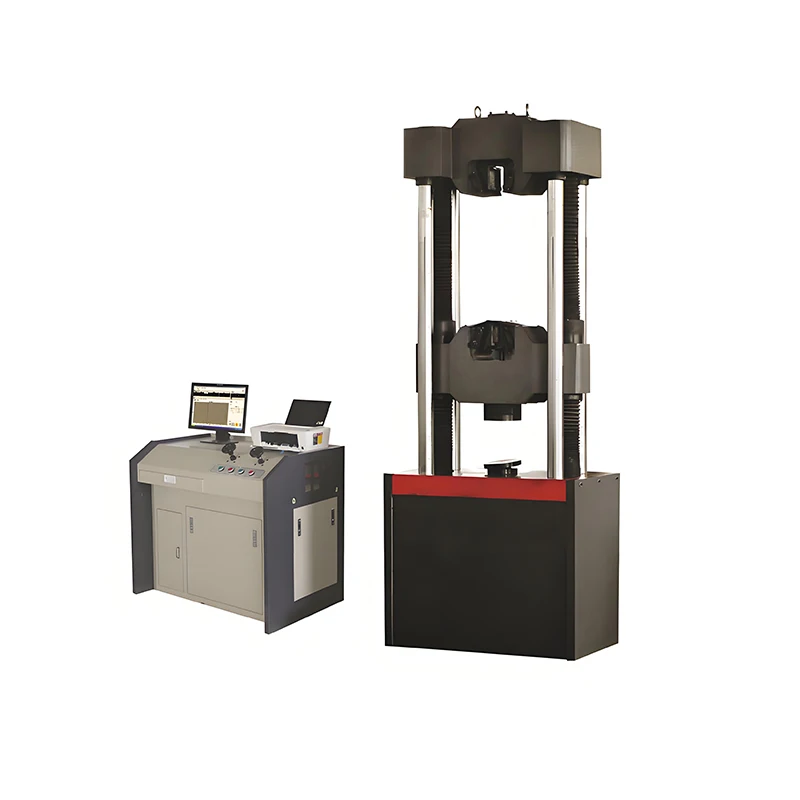

Technical Specifications and Performance Metrics: Capacity and Compatibility

When you choose a Paper Packaging Zero Drop Test Machine, you want reliable specs that fit your workflow. Our Derui zero drop testers are built to handle a wide range of packaging sizes and weights, making them highly versatile for U.S. manufacturers.

| Feature | Specification |

|---|---|

| Drop Height Range | 0 to 1 meter (0 to 39 inches) |

| Maximum Load Capacity | Up to 150 lbs (68 kg) |

| Package Size Compatibility | Supports cartons up to 40” x 40” x 40” |

| Drop Modes | Free fall, edge drop, corner drop |

| Control System | PLC-controlled zero drop system |

| Power Supply | 110V / 220V options available |

Performance Highlights:

- Accurate Drop Simulation: Mimics real-world shipping drops for paper cartons and corrugated boxes without damaging the equipment.

- Consistent Impact Testing: Runs repeatable tests to track packaging durability over time.

- Fast Setup: Easy to adjust for different carton sizes and test types, making it perfect for busy production floors.

- Compatible with Industry Standards: Fully supports ISTA 3A and ASTM D5276 testing requirements.

This capacity and compatibility mean you can test everything from small paper cartons to large corrugated boxes — ensuring your packaging survives any shipping challenge.

Compliance with Industry Standards: ISTA 3A, ASTM, and Beyond

Our Paper Packaging Zero Drop Test Machine is designed to meet key industry standards, including ISTA 3A and ASTM D5276. These certifications ensure your packaging tests are consistent, reliable, and trusted across the U.S. market.

Why Certification Matters:

| Standard | What It Means | Benefit for You |

|---|---|---|

| ISTA 3A | Simulates real-world transport drops | Ensures packaging holds up in shipping |

| ASTM D5276 | Standard test for free-fall drops | Provides standardized drop testing |

| Other Specs | Custom protocols on request | Fits unique packaging needs |

Certification Benefits at a Glance:

- Reliable test results that buyers and regulators trust

- Consistent packaging quality to reduce damage during shipping

- Easy compliance for shipments across the U.S. and beyond

- Reduces product returns by spotting weak packaging early

By choosing our zero distance drop tester, you’re aligning your paper packaging tests with industry best practices. This helps you avoid costly issues and win customer confidence every time.

Applications in Paper Packaging Manufacturing

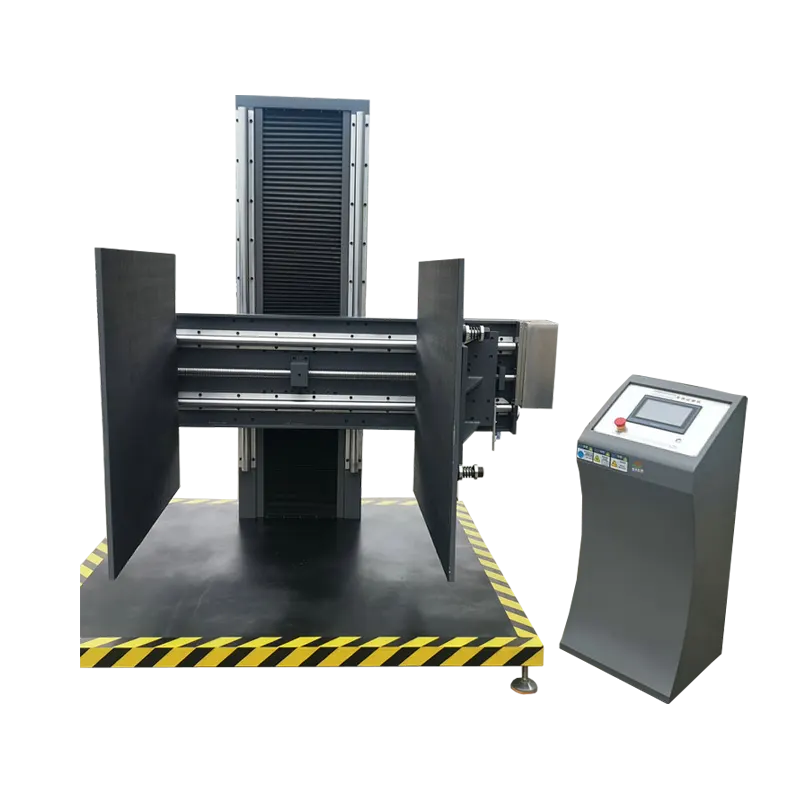

Integration with Lab Workflows

The Paper Packaging Zero Drop Test Machine plays a crucial role in modern packaging production. It helps manufacturers check how well their cartons and paper packaging can withstand real-world drops and impacts before shipping. By simulating free fall or edge drops, this machine spots weak points early, letting you fix issues before products reach customers.

Integrating the zero drop tester into your lab workflow is straightforward. It works well alongside other testing devices like compression testers and vibration simulators. Thanks to features like a PLC-controlled zero drop system and easy data output, lab teams can quickly record and analyze results. This helps speed up quality control processes without slowing down production schedules.

For U.S.-based manufacturers focused on meeting strict standards like ISTA 3A and ASTM D5276, this machine ensures compliance and consistency. Whether testing small cartons or heavy-duty corrugated boxes, it fits right into testing labs designed to handle a range of packaging sizes and types.

In short, the zero drop test machine not only verifies packaging durability but neatly complements existing lab setups—offering reliable, repeatable testing that improves product quality and reduces costly failures.

Why Derui Stands Out as Your Zero Drop Test Machine Supplier: Customer Success Metrics

When it comes to finding a reliable Paper Packaging Zero Drop Test Machine supplier, Derui consistently delivers results that matter. Our customers in the U.S. packaging market appreciate the durability, accuracy, and user-friendly design of our zero drop testers. Here’s why businesses keep choosing Derui:

- Proven Reliability: Over 95% of our customers report smoother lab workflows and fewer packaging failures after integrating our Packaging Drop Impact Machines.

- Consistent Accuracy: Our devices, including the popular ISTA 3A drop test equipment, provide precise and repeatable drop simulations, leading to better quality control.

- Improved Packaging Durability: Clients have noted a marked reduction in damaged cartons during shipping once using our corrugated box drop simulators.

- Strong Customer Support: Derui offers prompt and knowledgeable assistance ensuring minimal downtime with your zero distance drop tester.

- ROI You Can Trust: Many customers see faster packaging development cycles and lower product replacement costs – thanks to our heavy-duty carton drop analyzers built to last.

Derui is more than just a machine supplier; we’re a partner committed to helping you improve packaging quality and meet U.S. industry standards like ASTM and ISTA with ease. When you choose Derui, you’re investing in tested technology with a track record of customer success.

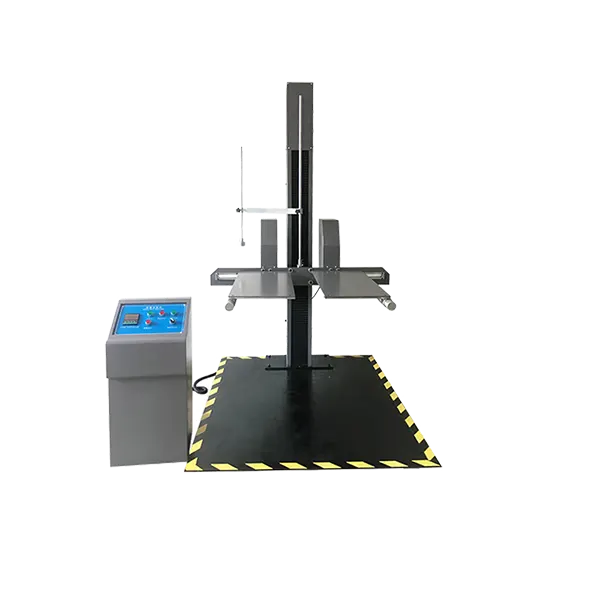

Buying Guide: Selecting the Right Paper Packaging Drop Tester

Choosing the right Paper Packaging Zero Drop Test Machine can be simple if you know what to look for. Here’s a quick checklist to guide you:

- Test Capabilities: Make sure the machine supports drop heights and package sizes you handle daily. Look for features like zero distance drop tester options and edge drop testing capabilities.

- Standards Compliance: Check if the tester meets industry standards like ISTA 3A and ASTM D5276. This ensures your packaging tests are reliable and accepted globally.

- Ease of Use: A PLC-controlled zero drop system with an easy interface saves time and cuts training costs.

- Durability: Go for heavy-duty carton drop analyzers that can handle repeated tests without frequent repairs.

- Integration: Your machine should fit well with your existing lab or production line workflow to avoid downtime.

- Size and Capacity: Confirm the tester can handle your typical carton sizes and weights – whether you need a large package zero height dropper or a smaller model.

Maintenance and ROI Calculator

- Routine Checks: Choose a tester with simple maintenance procedures. Regular calibration and parts replacement keep your testing accurate.

- Spare Parts Availability: Quick access to parts and local service providers reduces downtime.

- Energy Efficiency: Machines with lower power consumption cut long-term costs.

- Return on Investment: Think beyond the upfront price. A reliable tester prevents product damage, reduces packaging waste, and improves customer satisfaction — all boosting your bottom line.

By keeping these factors in mind, you’ll pick the right packaging drop impact machine that fits your budget and production needs, helping you meet U.S. market demands with confidence.

Frequently Asked Questions About Zero Drop Test Machines

What is a zero drop tester for paper packaging?

A zero drop tester simulates package impacts by dropping cartons from zero height, replicating sudden shocks or jarring during handling or transport. It helps check if your paper packaging can handle those quick impacts without damage.

Why is zero drop testing important for paper cartons?

Paper cartons often face bumps and drops during shipping. Zero drop testing reveals weak spots where the package might fail, letting you improve your design and avoid costly product damage or returns.

How does the Derui zero drop tester stand out?

Derui’s machine is built for accuracy and durability. It’s PLC-controlled, fits various carton sizes, and meets ASTM and ISTA 3A standards, making it a reliable choice for quality testing in U.S. packaging markets.

Is this equipment suitable for heavy-duty cartons?

Yes, Derui’s zero drop test machine handles heavy-duty cartons and large packages with ease, ensuring your toughest packaging gets tested for real-world impacts.

Can the zero drop tester simulate other drop types?

While designed specifically for zero-height drops, some models include edge drop or free-fall testing options. Derui offers versatile machines to cover these needs, like carton free fall testers or edge drop testing devices.

How often should I perform zero drop tests?

Testing frequency depends on your production volume and customer requirements. Many U.S. manufacturers run tests routinely during production to keep packaging consistent and compliant.

What maintenance does a zero drop test machine need?

Simple, regular upkeep like checking sensors, cleaning the drop platform, and verifying control settings ensures your tester runs smoothly and lasts longer.

Are there certifications I should look for?

Yes, ensure the machine complies with ISTA 3A and ASTM D5276 standards, which cover drop testing protocols widely accepted in the U.S. This helps guarantee your test results are trustworthy and recognized.

If you have more questions or want to see how our zero distance drop tester can fit your packaging process, feel free to contact us. We’re here to help you build stronger, safer paper packaging.

Ready to Enhance Your Packaging Durability? Contact Derui Today

If you’re looking to improve your paper packaging’s durability and reduce product damage, Derui’s Paper Packaging Zero Drop Test Machine is your go-to solution. Our zero distance drop tester and packaging drop impact machine are designed to meet US industry needs, ensuring your cartons and boxes withstand real-world handling and shipping challenges.

With easy integration into your workflow, reliable ISTA 3A drop test equipment, and strict compliance with ASTM D5276 standards, Derui gives you confidence in every test. Don’t settle for guesswork—get the precise results needed to protect your products and reputation.

Reach out to Derui today to learn more about our free fall test machine for cartons and how we can help you optimize packaging strength with a heavy-duty carton drop analyzer built for the US market. Let’s make your packaging tougher, smarter, and ready for anything.