What is a Packaging Double Wing Drop Test Machine

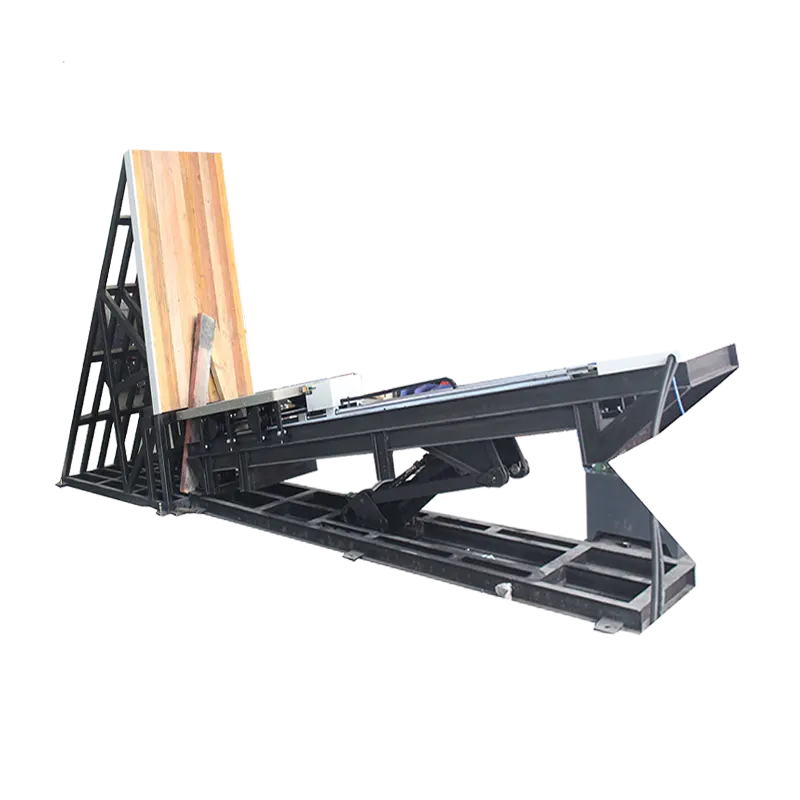

A Packaging Double Wing Drop Test Machine is specialized equipment designed to evaluate the durability and impact resistance of packaging by simulating realistic drop scenarios. Unlike traditional single wing or vertical drop testers, this machine features two independently controlled swinging arms—or wings—that hold and release the package from multiple angles. This double wing design allows for more precise and varied drop orientations, closely mimicking how packages might fall during actual handling and transportation.

The key components include the dual wing arms, adjustable clamps to secure the package, a drop height adjustment system, and automated controls for release timing. When activated, the wings swing the package outward, releasing it to drop freely from predetermined heights and angles. This mechanism enables testing from various directions in a single setting, offering a more comprehensive assessment compared to single wing testers that typically drop packages in a single direction or simple vertical drop machines that only simulate straight downward falls. The double wing setup enhances testing realism and accuracy, highlighting potential weak points in packaging design before products reach the market.

Key Features and Technical Specifications

The Packaging Double Wing Drop Test Machine offers several advantages thanks to its dual wing design, which allows for more realistic and consistent drop testing compared to traditional single wing or vertical drop testers.

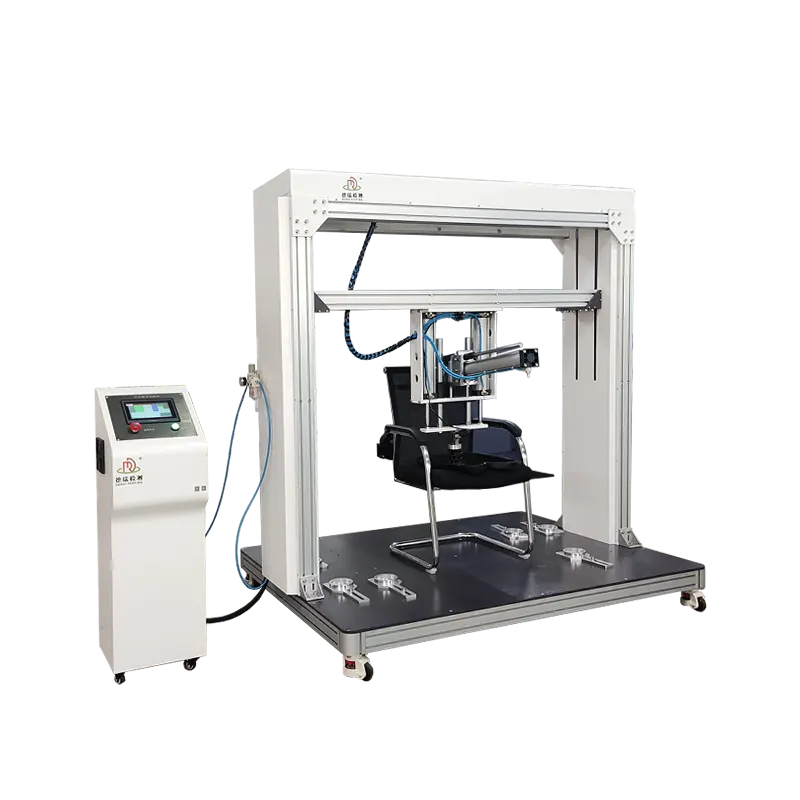

Dual Wing Mechanism and Advantages

- Simulates multi-directional drops more effectively

- Reduces test time by allowing simultaneous drops from both wings

- Enhances accuracy by controlling impact angles precisely

Adjustable Drop Height and Angles

- Drop heights adjustable from 0.5 to 2.0 meters (or customized as needed)

- Multiple angle settings to replicate various real-world drop scenarios

- Enables testing of diverse packaging types and sizes

Automated Control Systems and Data Acquisition

- User-friendly interface with programmable drop sequences

- Real-time monitoring and automated data collection

- Enables detailed analysis of drop impacts and packaging performance

Compliance with International Standards

- Meets ISTA, ASTM, and ISO drop test requirements

- Ensures your packaging passes rigorous, recognized tests for the U.S. market and beyond

Machine Capacity and Safety Features

| Feature | Specification |

|---|---|

| Max Sample Size | Up to 24″ x 24″ x 24″ (custom sizes available) |

| Max Sample Weight | Up to 50 lbs |

| Safety Features | Emergency stop, safety guards, overload protection |

| Build Material | Heavy-duty steel frame with durable surface |

This machine is built to handle different package materials and sizes while ensuring operator safety and reliable test results every time.

Why Choose a Double Wing Drop Test Machine for Packaging

A Packaging Double Wing Drop Test Machine offers several clear advantages over traditional testers:

- Better Testing AccuracyThe dual wing design controls the package’s drop angle precisely, making impact more consistent. This means your test results are more reliable.

- Real-World Drop SimulationUnlike single wing or vertical drop testers, it mimics the multi-directional drops packages face during shipping and handling. This gives a more accurate picture of durability.

- Reduces Damage and LossBy catching weak points early, it helps lower the chances of package failure, minimizing product damage and costly returns.

- Boosts Customer SatisfactionReliable packaging keeps products safe, which means happier customers and stronger brand trust.

- Cost-Effective TestingIt combines multiple drop angles in one setup, reducing the need for extra equipment and saving money on testing time.

Here’s a quick overview:

| Benefit | Why it Matters |

|---|---|

| Increased Testing Accuracy | Consistent, controlled impacts |

| Multi-Directional Simulations | Reflects real shipping conditions |

| Reduced Package Damage | Lowers product loss and return costs |

| Quality Assurance | Builds customer trust and satisfaction |

| Cost Effectiveness | Fewer machines, less testing time needed |

Choosing a double wing drop tester means investing in smarter, more efficient packaging testing.

Applications of the Double Wing Drop Test Machine

The Packaging Double Wing Drop Test Machine is widely used across various industries in the U.S. It’s essential for testing how packaging holds up in real-world conditions. Here’s where it shines:

- Electronics: Perfect for testing fragile items like smartphones, laptops, and other gadgets to ensure they survive shipping without damage.

- Food and Beverage: Helps verify that cartons and bottles can handle drops and impacts, maintaining product safety and presentation.

- Pharmaceuticals: Ensures medicine boxes and containers stay intact, protecting sensitive contents during transport.

- E-commerce: With packages tossed around more than ever, it mimics common drops to reduce returns from damaged goods.

The machine is ideal for testing various packaging materials such as cardboard, plastics, and composites. This flexibility makes it a go-to for:

- Packaging Material Testing: Evaluating strength and durability of cartons, plastic wraps, and mixed materials.

- Quality Control in Manufacturing and Logistics: Catching weak packages before they reach customers, reducing losses and returns.

- Research and Development: Innovating new packaging designs that better protect products while cutting costs.

Overall, the double wing design delivers reliable, multi-directional drop testing that matches real-life shipping challenges seen in U.S. markets.

How to Operate and Maintain Your Double Wing Drop Test Machine

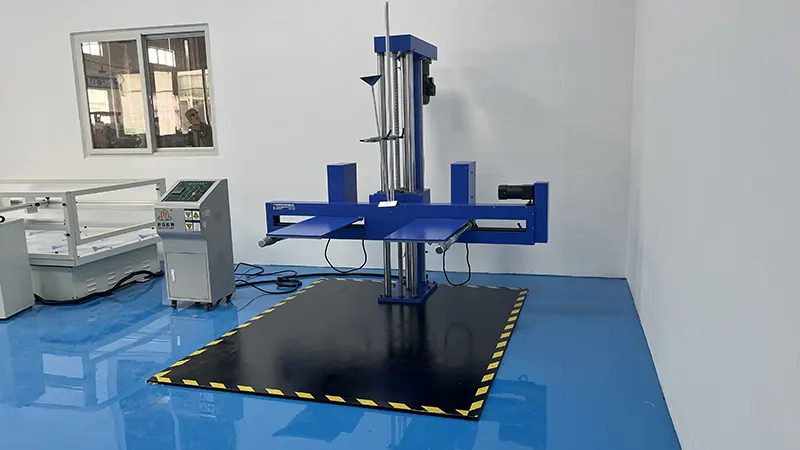

Operating Instructions

- Prepare the sample: Secure the package or product firmly on the double wing drop platform. Make sure it’s properly balanced to avoid uneven impacts.

- Set drop parameters: Use the control panel to adjust the drop height and angle based on your test requirements. The double wing design lets you select multiple impact directions easily.

- Start the test: Activate the machine through the automated system. The wings will lift and release the package according to the programmed settings.

- Collect data: The system records impact data automatically. Review the results on-screen or export them to your computer for further analysis.

Calibration and Maintenance Tips

- Calibrate regularly: Ensure accurate drop height and angle settings by calibrating sensors monthly or after any mechanical adjustments.

- Clean moving parts: Remove dust and debris from wings, hinges, and drop trays weekly to maintain smooth operation.

- Check for wear: Inspect belts, springs, and impact surfaces for damage or wear signs every quarter and replace as needed.

- Lubricate joints: Apply recommended lubricants to pivot points and mechanical linkages every two months to prevent stiffness.

Troubleshooting Common Issues

- Wing mechanism stuck: Check for obstructions and test manual wing movement. Tighten loose bolts and clean any buildup if necessary.

- Inaccurate drop height: Recalibrate sensors and confirm that settings match the displayed parameters.

- Data not recording: Restart the control system and verify software connections. Ensure all cables are properly connected.

- Machine won’t start: Inspect emergency stop and safety locks to confirm they are disengaged.

Safety Precautions

- Always wear safety glasses and gloves during operation and maintenance.

- Keep hands and loose clothing away from moving wings during drops.

- Use emergency stop buttons immediately if the machine behaves unexpectedly.

- Train all operators on machine functions and emergency procedures before use.

- Follow OSHA and local workplace safety guidelines to prevent accidents.

Frequently Asked Questions FAQs

How does the double wing mechanism improve testing accuracy

The double wing design offers controlled, multi-directional drops that better mimic real-world handling. Unlike single wing or vertical testers, it reduces random bounce and inconsistent impacts, giving you more precise and repeatable drop results. This means you can trust the packaging durability data for making smarter improvements.

What types of packaging can be tested

This machine handles a wide range of packaging types, including cardboard boxes, plastic containers, composite materials, and even delicate electronic packaging. Whether it’s food and beverage cartons, pharmaceutical boxes, or e-commerce shipments, the double wing drop test machine covers them all.

Can the machine simulate complex drop scenarios

Yes, it can. The adjustable drop height and angle settings let you replicate various real-life drop situations — from corner drops to edge and flat surface impacts. This flexibility helps you test packaging against multiple drop scenarios in one go, aligning with ISTA and ASTM standards.

Warranty and after sales service from Derui

Derui stands behind their double wing drop test machines with solid warranty terms and reliable after sales support. They offer technical assistance, spare parts availability, and user training to ensure smooth operation. You’ll find responsive customer service to keep your packaging drop tester running efficiently.

Why Choose Derui’s Double Wing Drop Test Machine

Derui stands out in the US market with a strong reputation backed by years of experience in packaging drop testers. Companies trust us because we deliver reliable, accurate drop test machines designed to meet local needs.

What Makes Derui Different

| Feature | Benefit |

|---|---|

| Proven Brand History | Trusted by industries across electronics, food, pharma, and e-commerce sectors |

| Customer Success Stories | Real-world results showing reduced product damage and improved quality control |

| Customization Options | Tailor drop heights, angles, and control systems to fit unique packaging types |

| Technical Support | Responsive US-based support to maximize uptime |

| Service & Spare Parts | Quick access to parts and maintenance to keep machines running smoothly |

| Competitive Pricing | Cost-effective solutions without sacrificing quality |

| Flexible Delivery | Fast shipping options across the United States |

Choosing Derui means investing in a double wing drop test machine that delivers durable, precise testing with excellent after-sales care—perfect for businesses wanting to ensure package reliability and meet ISTA, ASTM, or ISO standards efficiently.