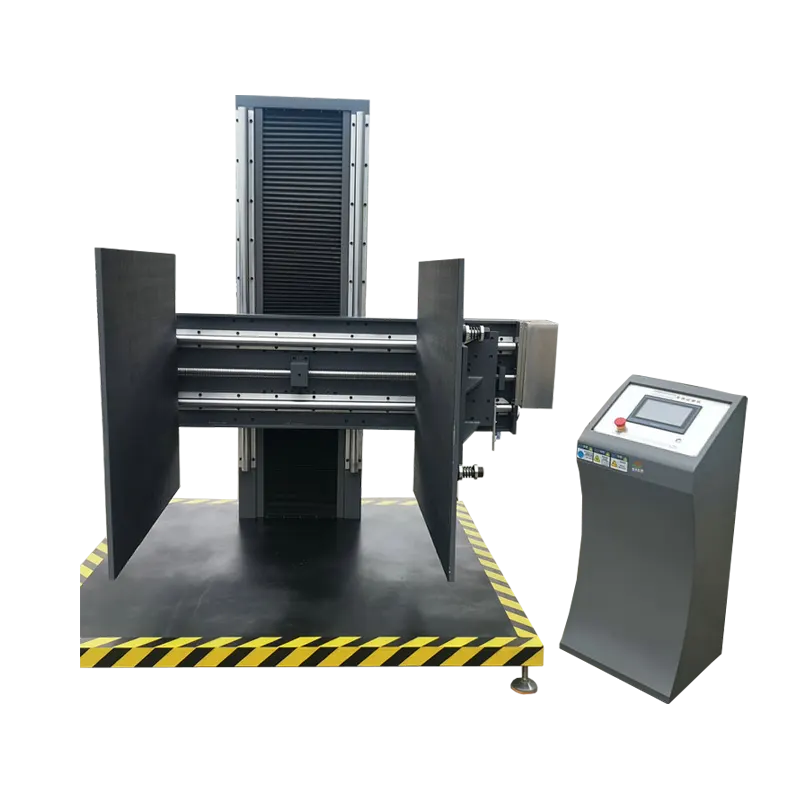

The inclined impact tester machine is a high-precision detection device specifically designed to simulate the impact conditions that goods may encounter during transportation. It is widely used in the packaging industry, logistics sector, and various product research and development and quality control processes. Its purpose is to accurately assess the performance of goods and packaging under impact loads, providing a scientific basis for ensuring the safety of goods transportation and optimizing packaging design.

The International Safe Transit Association (ISTA) is an association composed of professionals and institutions and is the authoritative organization in international packaging and transportation. ISTA is dedicated to the development, design and cost-benefit assessment of protective transport packaging. When your packaging design passes the ISTA test, you can be sure that this packaging will effectively protect the product in continuous transportation environments and will not be harmed by foreseeable factors.

Basic requirements:

ISTA 1A: Fixed displacement vibration and shock test

ISTA 2A: Environmental conditioning, pressure, fixed displacement or random vibration and shock test

ISTA 3A: Environmental conditioning, random vibration with and without top load, shock test。

Working Principle

1.Based on the principle of converting an object's potential energy into kinetic energy, the package is slid to the end at a predetermined position and gains a certain impact speed, then collides with an impact plate perpendicular to the speed direction to achieve the intended test purpose.

2.By applying the principle of converting potential energy of an object into kinetic energy, the package is freely slid to a fixed position and gains a certain impact velocity. Then it collides with an impact plate whose acceleration direction is perpendicular to that velocity to achieve a certain test.

Product Features

1、Flexible positioning electric trolley, easy to fix at simple positions, achieving the required speed variation values;

2、The height of the pulley is relatively low, which is conducive to the installation of test samples. The reinforced shock-resistant plate ensures the structural stability.

3、It can be operated by remote control, fully ensuring the safety of the test personnel.

4、The sliding table surface can be adjusted to be horizontal, and the angle adjustment is driven by a cylinder, which is convenient for users to install specimens.

5、When installing, the customer only needs to fix the machine on the ground. There are no other complicated operations or installations, and it is convenient for testing.

1. Reinforced Structural Design for Unparalleled Stability

- Thickened square pass: Forms the core support, with increased thickness for superior strength and rigidity, precisely machined to fit well with other components and minimize weak points.

- Thickened I - beams: Efficiently distribute loads, with their “I” shape enhancing load - bearing capacity as main support pillars, ensuring the machine stays immovable during impact.

- Solid steel: Used throughout for durability and stability, with excellent mechanical properties to absorb and dissipate impact energy, preventing displacement and ensuring accurate data collection.

2. Aesthetic and Durable Appearance Through Advanced Coating Technology

- Paint spraying process: Creates a smooth and uniform finish.

- Anti - rust and anti - corrosion paint: Protects metal components from environmental factors, extending the machine's lifespan and reducing maintenance needs, while also giving it a modern and professional look.

3. High - Load - Bearing Track and Impact Pulley System

- Tracks: Made of high - strength steel, with a maximum load - bearing capacity of 500kg, precision - machined for a smooth surface to minimize friction and ensure accurate positioning.

- Impact pulleys: Can also handle a maximum load of 500kg, rotate smoothly, guide the movement of the platform and specimen, and use high - quality bearings for low friction and long - term reliability.

4. Double Oil Cylinder Lifting Device for Enhanced Stability

- Dual - cylinder design: Provides greater lifting force and stability compared to a single - cylinder system, with precise calibration for synchronous operation to maintain the horizontal level of the testing platform.

- Vibration and shock dampening: Helps to further improve the machine's stability and the accuracy of data collection.

5. Low - Friction Impact Pulley Design for Accurate Data Collection

- High - quality pulleys: Feature smooth and precisely machined surfaces to reduce contact area with cables or belts, minimizing sliding friction.

- Accurate data collection: Lower friction enables the platform to move more freely, accurately transmitting impact forces and specimen displacement, and reducing interference in measurements.

6. Anti - Secondary Impact Impact Plate for Precise Data

- Anti - secondary impact mechanism: Absorbs remaining energy after the initial impact, preventing the test platform from rebounding and hitting the plate again.

- Data accuracy and component protection: Ensures the collected data represents the actual impact of the first hit and protects machine components from excessive wear caused by repeated impacts.

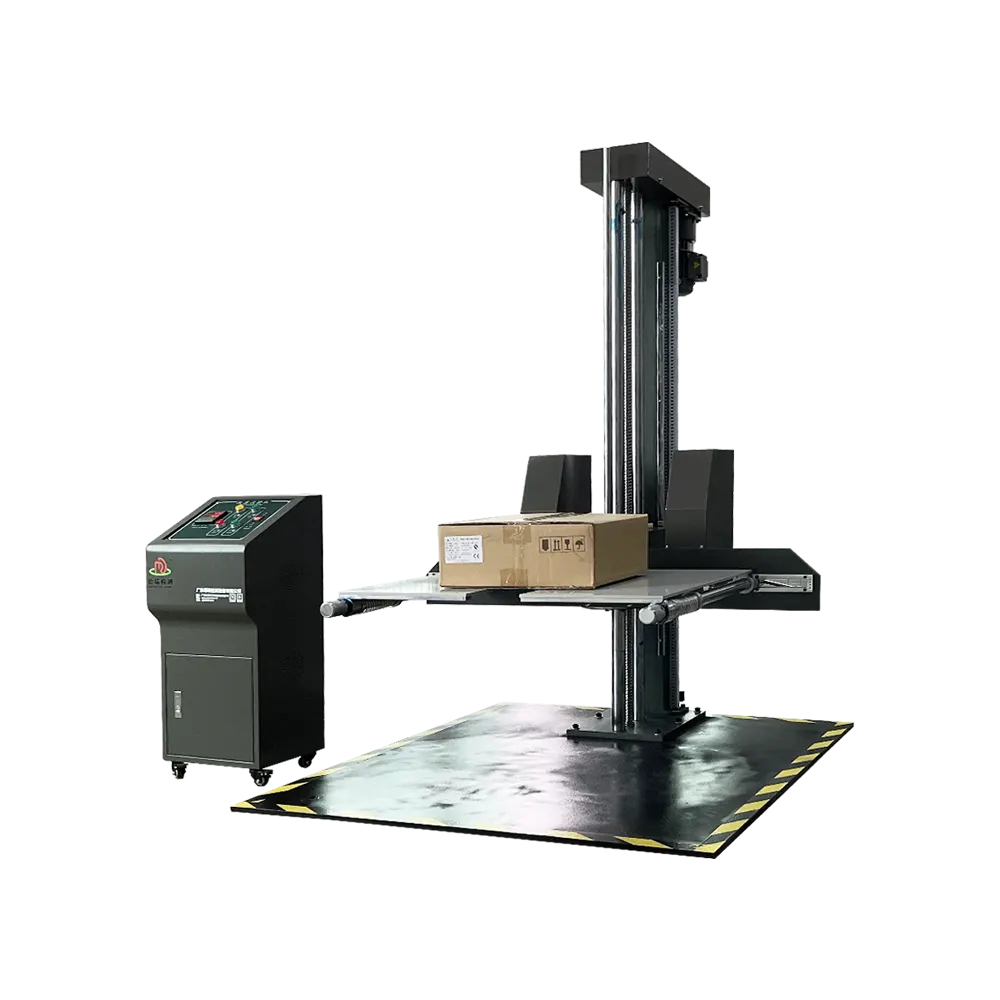

Why conduct inclined plane impact tests?

The inclined plane impact tester simulates the impact that products may experience during handling and transportation under controlled conditions. Through inclined plane impact tests, products can reproduce test results under different packaging parameters, such as comparing the protective capabilities of product packaging under different design conditions, including various cushioning materials, filling materials, and different types of cardboard. By testing the consistency of effectiveness in actual conditions such as storage and transportation and during theoretical design verification, it aims to maximize the protective role of packaging as much as possible.

Through the inclined impact test in transport packaging inspection, it can provide packaging designers with appropriate dimensions, materials and product layout diagrams, offer solutions for transport packaging design, make the design work more complete, and truly help manufacturers reduce packaging costs.

Maintenance and upkeep:

To ensure that the inclined plane impact test bench equipment is always in good technical condition, ready for operation at any time, reduce the number of days of downtime due to faults, improve the mechanical integrity rate and utilization rate, reduce mechanical wear, extend the service life of the machinery, lower the operating and maintenance costs of the machinery, and ensure safe production, it is necessary to strengthen the maintenance and upkeep of the inclined plane impact test bench, the Dongguan Ruiven inclined plane impact test bench equipment.

1、The maintenance of the inclined plane impact test bench follows the principle of "equal emphasis on maintenance and repair, with prevention as the priority", ensuring regular maintenance and mandatory implementation. The relationship between usage, maintenance, and repair should be properly handled. It is not allowed to use without maintenance or repair without maintenance.

2、Maintenance personnel and maintenance departments should adhere to the "three inspections and one handover (self-inspection, mutual inspection, dedicated inspection, and one-time qualified handover)" principle, constantly summarize maintenance experience, and improve maintenance quality.

3、The maintenance of the inclined impact testing machine should persistently promote the "cross" operation method with "cleaning, lubrication, adjustment, tightening and anti-corrosion" as its main contents. A routine maintenance and regular maintenance system should be implemented, strictly following the maintenance cycle and inspection items specified in the user manual.

4、Routine maintenance of the slope impact test bench is carried out before, during and after the mechanical operation, mainly involving cleaning and inspection of critical and vulnerable components (such as mechanical safety devices), as well as checking the levels of coolant, lubricant, fuel, and instrument indications. Routine maintenance is performed by the operators themselves, who must carefully fill out the "Routine Maintenance Record of Machinery".

5、First-level maintenance: General cleaning, tightening, and lubrication operations are carried out, and partial adjustment operations are performed to maintain the mechanical equipment in good technical condition. The asset management personnel of the user unit issue the "Equipment Maintenance and Lubrication Notice" according to the maintenance plan and distribute it to the operation teams. The operators themselves complete the tasks, and the team leaders of the operation teams check and supervise.

6、Secondary maintenance: It includes all the contents of primary maintenance, with inspection and adjustment as the focus, to ensure that all assemblies, mechanisms and parts of the machinery maintain good working performance. The asset management personnel of the user unit shall issue the "Equipment Maintenance and Lubrication Notice" to the operation team. It is mainly completed by the operator himself. When the operator has difficulty completing it, it can be entrusted to the repair department. The asset management personnel of the user unit and the team leader of the operation team shall inspect and supervise.

7、Seasonal maintenance of the slope impact test bench: The main contents include replacing lubricating oil and fuel suitable for the season, taking anti-freezing measures, and adding anti-freezing facilities, etc. It is organized and arranged by the using department, and inspected and supervised by the operation team leader.

8、Maintenance during the running-in period of the slope impact test bench: After the running-in period of new machines and those that have undergone major overhauls, running-in period maintenance must be carried out. The main contents include cleaning, tightening, adjusting and replacing lubricating oil. This is completed by the using department, with inspection by the asset manager and supervision by the asset management department.

9、Maintenance for the slope impact test bench during relocation: Before the mechanical equipment is transferred to another site, it should undergo relocation maintenance. The maintenance tasks can be carried out based on the technical condition of the equipment, and anti-corrosion treatment may be necessary. The relocation maintenance shall be organized and implemented by the unit that moves out the equipment, with inspection by the project department and the asset manager, and supervision by the asset management department.