What is a Differential Scanning Calorimeter DSC

A Differential Scanning Calorimeter (DSC) is a thermal analysis instrument used to measure how much heat a sample absorbs or releases as its temperature changes. It helps us understand the thermal properties of materials by tracking heat flow differences between a test sample and a reference material during controlled heating or cooling.

Basic Principle of DSC Technology

DSC works on a simple idea: when a material undergoes physical or chemical changes—like melting, crystallizing, or glass transitions—it either absorbs or releases heat. The DSC detects this change in heat flow relative to its temperature program, providing a precise measurement of these thermal events.

How DSC Measures Heat Flow

- The instrument heats or cools both the sample and a reference under the same conditions.

- It continuously records the difference in heat flow needed to maintain both at the same temperature.

- This heat flow difference corresponds directly to thermal transitions in the sample.

Key Components of a DSC Instrument

| Component | Function |

|---|---|

| Sample and Reference Pans | Hold the materials being tested and compared |

| Furnace | Controls the temperature during analysis |

| Heat Flow Sensors | Measure energy difference between sample and reference |

| Temperature Controller | Regulates precise heating/cooling rates |

| Data Acquisition System | Records and displays heat flow and temperature data |

These parts work together to deliver accurate, real-time heat flow data, making a DSC an essential tool in thermal analysis.

Working Principle of a DSC

A differential scanning calorimeter (DSC) works by measuring how much heat a sample absorbs or releases as it’s heated or cooled. This helps detect key physical changes like melting, crystallization, and glass transitions—events where materials absorb or release heat differently than expected.

How DSC Detects Phase Transitions

- Melting: When a solid turns to liquid, the sample absorbs heat without a temperature rise. DSC records this as an endothermic peak.

- Crystallization: This is the opposite, where the sample releases heat as liquid turns to solid, showing as an exothermic peak.

- Glass Transitions: Unlike melting, this is a gradual process where a material softens without changing state. DSC detects it as a step change in heat flow.

Heat Flow vs Temperature Program

- Heat Flow: This is the actual measurement, showing how much energy the sample gains or loses over time.

- Temperature Program: The controlled way the DSC changes temperature—heating or cooling at a set rate. Different programs let you analyze samples under realistic conditions.

Types of DSC

| Type | How It Works | Benefits | Common Use |

|---|---|---|---|

| Power-Compensated | Keeps sample and reference at the same temperature by adjusting power | Fast response, precise control | Research, fast scans |

| Heat Flux | Measures temperature difference between sample and reference | Simpler, lower cost | Routine quality control |

Understanding these basics helps you choose the right DSC setup for your material analysis.

Applications of DSC in Various Industries

Differential Scanning Calorimeter (DSC) plays a crucial role across many industries by providing insights into material properties and thermal behaviors.

Polymer and Plastics Industry

DSC helps measure crystallinity and thermal stability in polymers and plastics. Knowing how a plastic melts or crystallizes allows manufacturers to improve strength, flexibility, and durability.

Pharmaceuticals

In drug development, DSC tests purity, polymorphism, and stability of compounds. It helps detect different crystal forms that impact drug efficacy and shelf life.

Food Industry

DSC is widely used to analyze melting points, oxidation, and other thermal events in foods. This helps in quality control and understanding how ingredients behave under heat.

Materials Science

From composites to metals and ceramics, DSC tracks phase transitions and thermal properties, aiding in designing stronger, more reliable materials.

Other Niche Applications

DSC assists in evaluating energy materials, coatings, and adhesives, where knowing thermal behavior can improve performance and lifespan.

By covering such diverse uses, DSC stands out as a versatile, valuable tool across sectors focused on material quality and reliability.

Advantages of Using DSC in Thermal Analysis

Differential scanning calorimeter (DSC) offers several benefits that make it a go-to tool for thermal analysis in many industries. Here’s why:

- High sensitivity and accuracyDSC instruments can detect very small heat changes, providing precise data. This helps you catch even subtle thermal events like glass transitions or minor crystallization.

- Small sample size neededYou don’t need much material for testing. DSC works well with tiny samples, which saves resources and is perfect for limited or expensive materials.

- Multiple thermal events measured simultaneouslyDSC tracks several processes at once, such as melting, crystallization, and curing. This efficiency helps speed up analysis without missing important details.

- Minimal sample preparationSamples usually need little to no special treatment before testing, making DSC fast and user-friendly. This reduces setup time and keeps results reliable.

These advantages make DSC the ideal choice for accurate, efficient, and resource-friendly thermal analysis.

Important Parameters and Interpretation of DSC Data

Understanding Differential Scanning Calorimeter (DSC) data is key to getting the most out of your thermal analysis. Here are the main terms and tips to help you interpret your results correctly.

Key Terms Explained

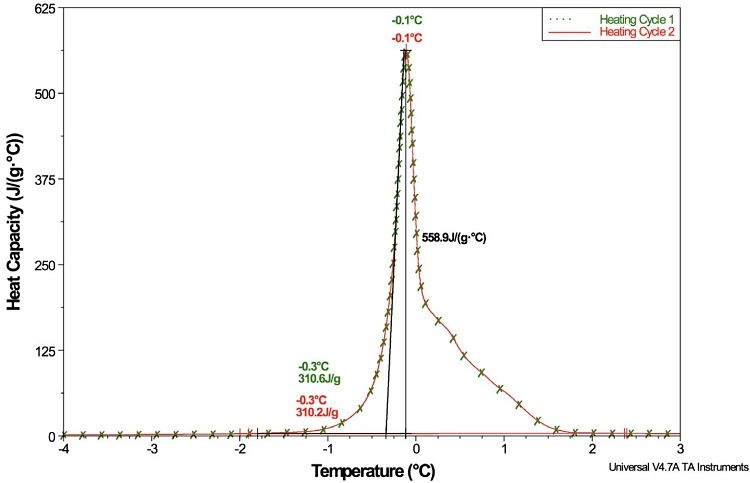

- Onset TemperatureThis is where a thermal event starts, like melting or a phase change. It’s the point where the heat flow curve begins to deviate from the baseline.

- Peak TemperatureThe temperature at which the heat flow reaches its maximum or minimum during an event such as melting or crystallization. This helps identify the exact point of a thermal transition.

- Enthalpy Change (ΔH)The total heat absorbed or released during the event, typically measured in joules per gram (J/g). This value tells you about the energy involved in melting, crystallization, or glass transition.

Interpreting DSC Curves in Practice

- Melting and crystallization often appear as endothermic (heat absorbed) or exothermic (heat released) peaks.

- Glass transitions (Tg) show up as a step change rather than a peak, reflecting the material’s change from a hard to rubbery state.

- Multiple events can overlap, so clear baseline correction is essential for accurate analysis.

Common Pitfalls and Tips for Accurate Readings

- Sample size matters: Too large or too small samples affect heat flow accuracy. Use consistent amounts, typically 5-10 mg.

- Baseline stability: Check your baseline regularly and run blank tests to ensure no drift.

- Heating rate: Faster heating can shift peak temperatures, while too slow can extend testing time. Find a balance, often 10°C/min works well.

- Crucible type: Use the right sample pan (aluminum or platinum) to avoid contamination and ensure good thermal contact.

- Repeat tests: Run duplicates to verify consistency.

By focusing on these parameters and following these simple tips, interpreting DSC data becomes straightforward and reliable for your materials analysis needs.

Choosing the Right DSC Instrument

When picking a differential scanning calorimeter (DSC) for your lab or production needs, it’s important to consider a few key factors:

- Temperature Range: Make sure the DSC can handle the temperatures your samples require, whether very low or high.

- Sensitivity and Accuracy: Look for instruments that detect subtle heat flow changes for precise analysis.

- Software Features: User-friendly software with strong data analysis tools helps speed up results and improves interpretation.

- Sample Size and Throughput: Check if the DSC supports the quantity and type of samples you typically test.

- Calibration and Maintenance Support: Reliable post-sale service ensures consistent performance over time.

Derui’s DSC instruments stand out with their advanced temperature control and high sensitivity, ideal for industries like polymers, pharmaceuticals, and materials science. Their models offer robust software for detailed thermal analysis, including features for purity analysis, crystallinity, and thermal stability testing.

Derui also provides customizable solutions tailored to specific testing needs, plus dependable after-sales support to keep your DSC running smoothly. This makes Derui a trusted choice for customers across the U.S. looking for both performance and service.

Maintenance and Calibration of DSC Equipment

Keeping your Differential Scanning Calorimeter (DSC) in good shape is essential for reliable thermal analysis results. Routine maintenance includes cleaning the sample holders, checking for any leaks, and ensuring that the sensors are free from dust or residues. Regular inspection helps prevent unexpected downtime and maintains measurement accuracy.

Calibration is equally important. Over time, sensors can drift, affecting heat flow and temperature readings. Calibrating your DSC with standard materials—like indium or zinc—ensures your data stays precise and consistent. Schedule calibrations based on the manufacturer’s recommendations or after any major repairs.

Derui supports customers with comprehensive service policies. Their team offers timely technical support, guidance on proper maintenance routines, and quick calibration services to keep your equipment performing at its best. This commitment helps U.S. users maximize their DSC’s lifespan and data accuracy.

Latest Trends and Innovations in DSC Technology

Differential Scanning Calorimeter (DSC) technology is evolving fast to meet more precise and complex thermal analysis needs. One big advancement is Modulated DSC (MDSC), which separates overlapping thermal events by applying a small oscillation to the temperature. This helps get clearer data on glass transitions, melting points, and crystallization — making it easier to understand complex materials.

Another notable innovation is micro DSC, which requires very tiny samples. This is great for when you have limited material, like in pharmaceuticals or specialty polymers, and still want accurate heat flow readings.

We’re also seeing more integration of DSC with other analytical tools, such as Thermogravimetric Analysis (TGA) combined with DSC in one instrument. This allows simultaneous measurement of mass changes and heat flow, giving a fuller picture of material properties, stability, and reactions.

Looking ahead, thermal analysis is moving toward even better sensitivity, faster run times, and smarter software with AI-driven data interpretation. The goal is to make DSC easier to use while expanding its applications in energy materials, coatings, and nanocomposites — especially important for U.S. industries pushing innovation.

Why Choose Derui for Your DSC Needs

Derui stands out as a trusted name in the field of differential scanning calorimeters (DSC) across the United States. With years of experience, Derui combines innovation and reliability to deliver instruments that meet the high demands of thermal analysis in various industries.

Brand Credibility and Innovation History

- Over a decade of experience in designing and manufacturing precise DSC instruments

- Continuous innovation, including power-compensated and modulated DSC models

- Proven track record of serving sectors like pharmaceuticals, polymers, food, and materials science

Commitment to Quality and Precision

- High-sensitivity DSC devices ensuring accurate heat flow measurements

- Rigorous quality control and testing on every instrument

- User-friendly software designed for clear DSC data interpretation and easy operation

- Customizable solutions tailored to your specific temperature range and sensitivity needs

Case Studies and Testimonials

- Pharmaceutical labs report enhanced purity and polymorphism testing

- Polymer manufacturers increased efficiency in crystallinity and thermal stability analysis

- Food industry clients rely on Derui’s DSC for precise melting and oxidation measurements

Contact and Purchasing Information

To learn more about Derui’s DSC instruments, request a quote, or schedule a demo, you can reach out directly:

| Contact Method | Details |

|---|---|

| Phone | 1-800-DERUI-DSC |

| sales@deruidsc.com | |

| Website | www.deruidsc.com |

| Customer Support | Available Monday to Friday, 8 am – 6 pm EST |

Choosing Derui means partnering with a company committed to delivering thermal analysis solutions that fit your exact needs, backed by reliable support and ongoing innovation.