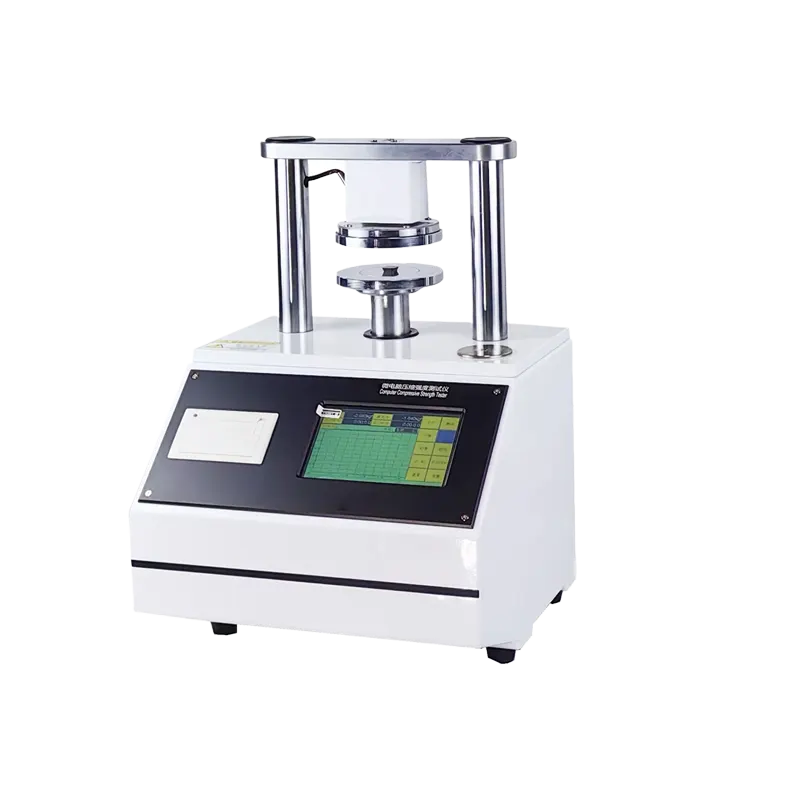

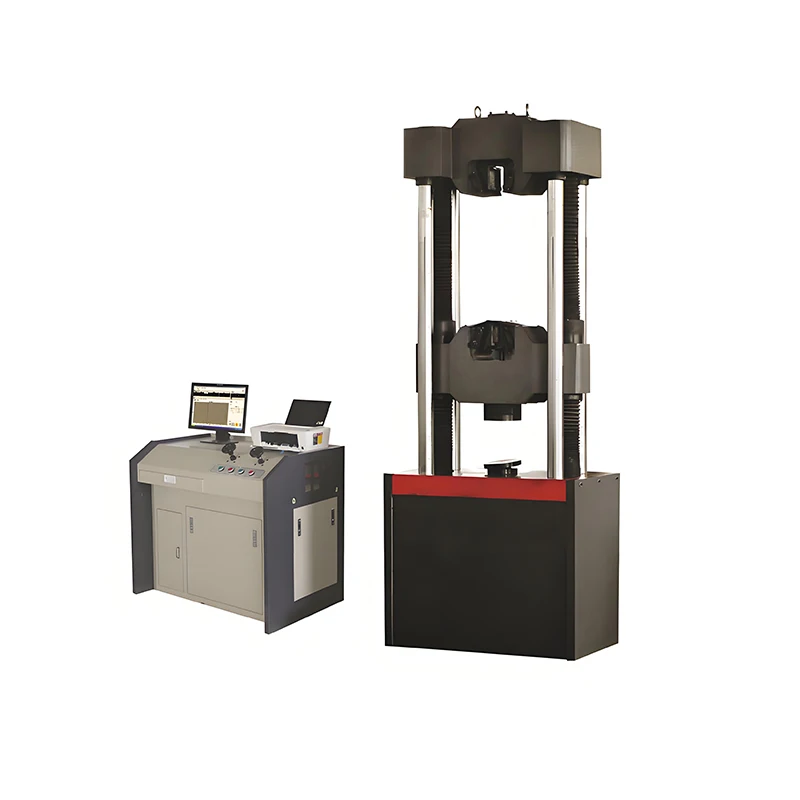

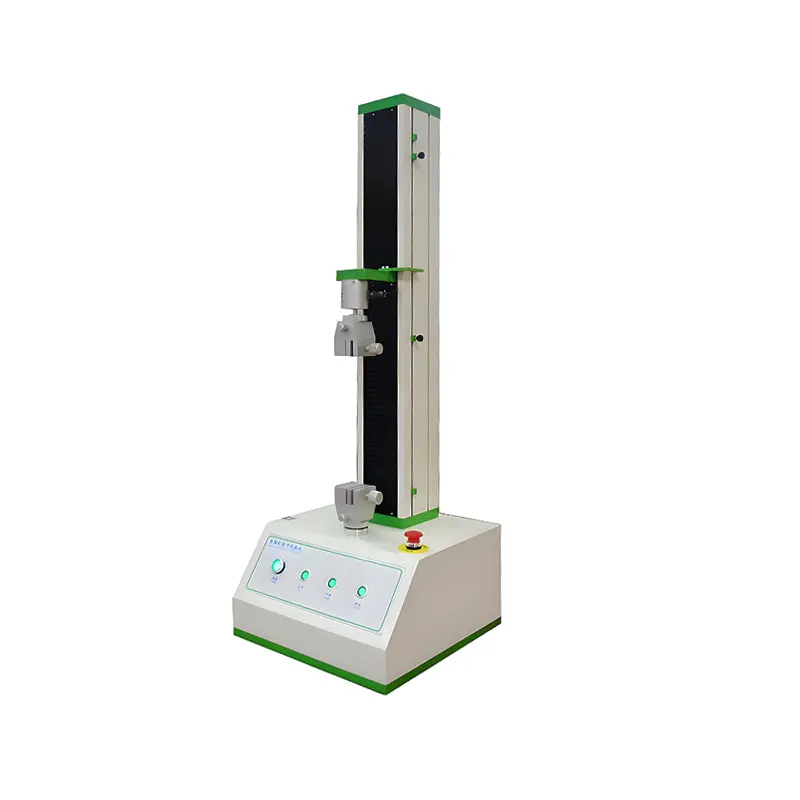

Our desktop tensile testing machine is renowned for its outstanding performance and versatile applications, suitable for various industries. This testing machine is compactly designed and easy to operate, making it an ideal and efficient material testing tool in laboratories. Whether you need to test metals, plastics or rubbers, the desktop tensile testing machine can provide you with precise and reliable test results. Choose our testing machine to ensure the efficiency and accuracy of your experiments and quality control processes.

This testing machine is mainly used for conducting mechanical tests such as tensile, compressive, flexural, shear, peel and tear tests on samples like electronic materials, small hardware parts and solar photovoltaic modules. Meanwhile, it can perform tests and data processing in accordance with various standards including GB, ISO, JIS, ASTM, DIN and those provided by users.

Functional Features

1.Advanced chip integration technology and professionally designed data acquisition and amplification system feature high integration, stability, reliability and ease of use. The control software can automatically calculate tensile strength, yield strength, compressive strength, fracture strength, peel strength, elastic modulus, elongation and other test data. Open formula editing can automatically calculate force, stress, displacement, deformation and other data results at any specified point during the test process. The control and data processing of the test process comply with the requirements of the corresponding national standards for metallic and non-metallic materials.

2.Control modes: Fixed speed, fixed displacement, fixed load, fixed load increase rate, fixed stress, fixed stress increase rate, fixed strain, fixed strain increase rate, etc. are available for selection.

3.Automatic zeroing: After the test begins, the measurement system automatically zeros.

4.Automatic gear shifting: Automatically switch to the appropriate range according to the load size to ensure the accuracy of the measurement data.

5.Automatic data saving: Test data and test conditions are automatically saved, eliminating the risk of data loss due to forgetting to save.

6.Batch testing: For samples with the same parameters, a batch of tests can be completed in sequence after one-time setting.

7.Display mode: Data and curves are dynamically displayed during the test process.

8.Curve Traversal: After the test is completed, the curve can be reanalyzed. Use the mouse to find the data corresponding to each point on the test curve.

9.Curve selection: You can choose to display and print curves such as stress-strain, force-displacement, force-time, and displacement-time.

10.Unit Switching: Force units: (g, kg, N, lb), Stress units: (kg/mm², N/mm², MPa, lbf/in²), Displacement units: (m, mm, in)

11.Test Report: The test report can be programmed and printed in the format required by the user, and can be exported as WORD, EXCEL, and PDF files.

12.Test Data: Powerful result data query function, historical test records can be queried at any time through the database.

13.Safety protection: When the load exceeds the maximum by 2% to 10%, safety protection is automatically activated.

14.It can automatically detect and calculate the mechanical performance indicators of the sample, and also allows manual intervention in the analysis process. According to the requirements of relevant standards, the automatic analysis results can be corrected to improve the accuracy of the data.

Typical Application Scenarios

- Material R&D and Quality Control

- Testing tensile strength, elongation at break, elastic modulus, and other parameters of materials such as plastics, rubber, metals, paper, and textiles.

- Verifying whether materials comply with industry standards (e.g., ISO, ASTM, GB, etc.).

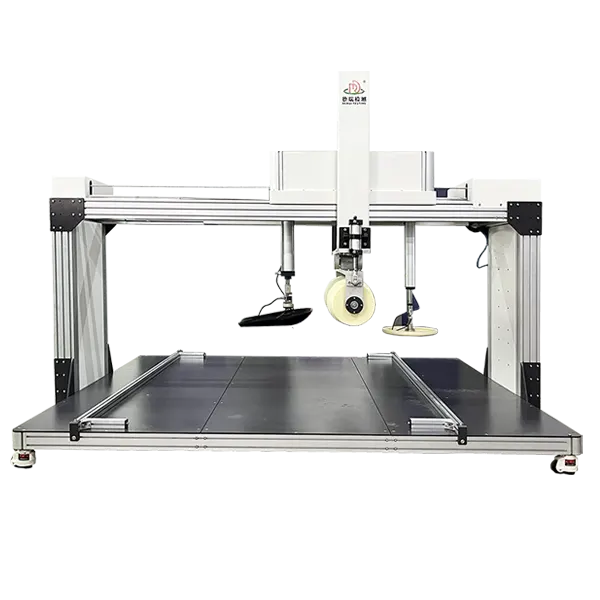

- Component Performance Testing

- Evaluating the tensile strength, compressive strength, or fatigue life of small components such as screws, springs, connectors, and cables.

- Assessing the connection reliability of assembled products (e.g., button press tests, wire terminal pull-out force tests).

- Teaching and Scientific Research Experiments

- Used in material science, mechanical engineering, and other disciplines for mechanics experiments in higher education, helping students intuitively understand material properties.

- Supporting customized experimental protocols to meet the precise testing requirements of scientific research projects.