Introduction to Charpy Pendulum Impact Testing

Impact testing plays a crucial role in material science by evaluating how materials behave under sudden forces or shocks. It helps engineers understand a material’s toughness—its ability to absorb energy and resist fracture when struck. This information is essential for predicting performance in real-world conditions where materials face dynamic loads.

The Charpy pendulum impact tester is a widely recognized standard device used to conduct these tests. It measures the energy absorbed by a notched specimen when struck by a swinging pendulum. This quick and reliable test provides valuable data on material impact resistance, helping identify brittle or ductile behavior.

In industries like automotive, aerospace, and construction, Charpy impact testing is a key part of quality assurance and safety protocols. By confirming material toughness, manufacturers reduce the risk of unexpected failures and ensure products meet strict safety standards. This testing method remains a cornerstone for engineers and material scientists aiming to guarantee durability and reliability.

What Is a Charpy Pendulum Impact Tester

A Charpy pendulum impact tester is a device used to measure the impact toughness of materials—basically, how much energy a material can absorb before it breaks under sudden force. It’s widely used in quality control and material research to understand how materials behave under stress.

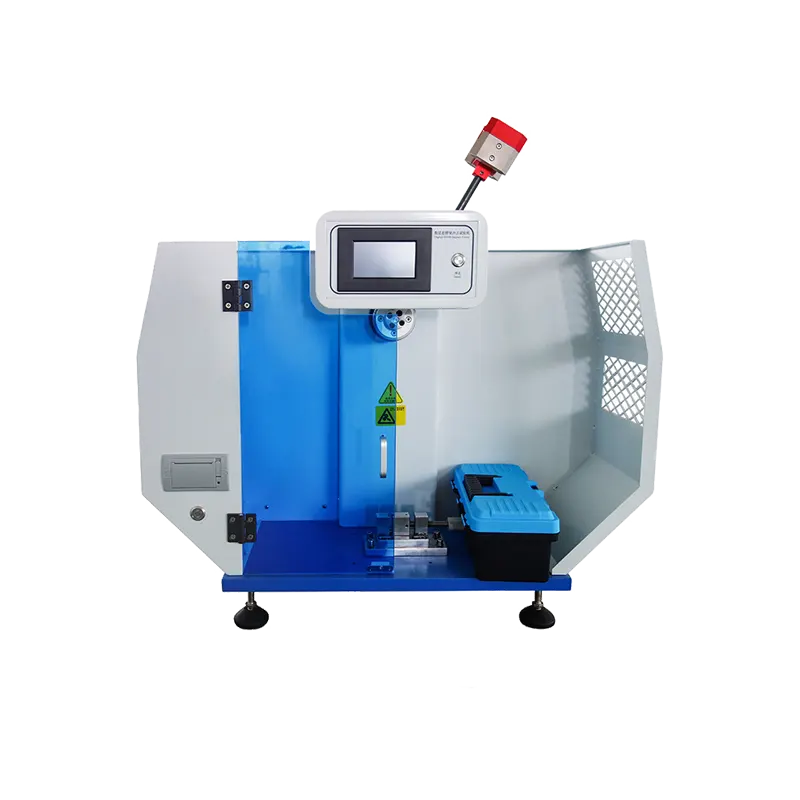

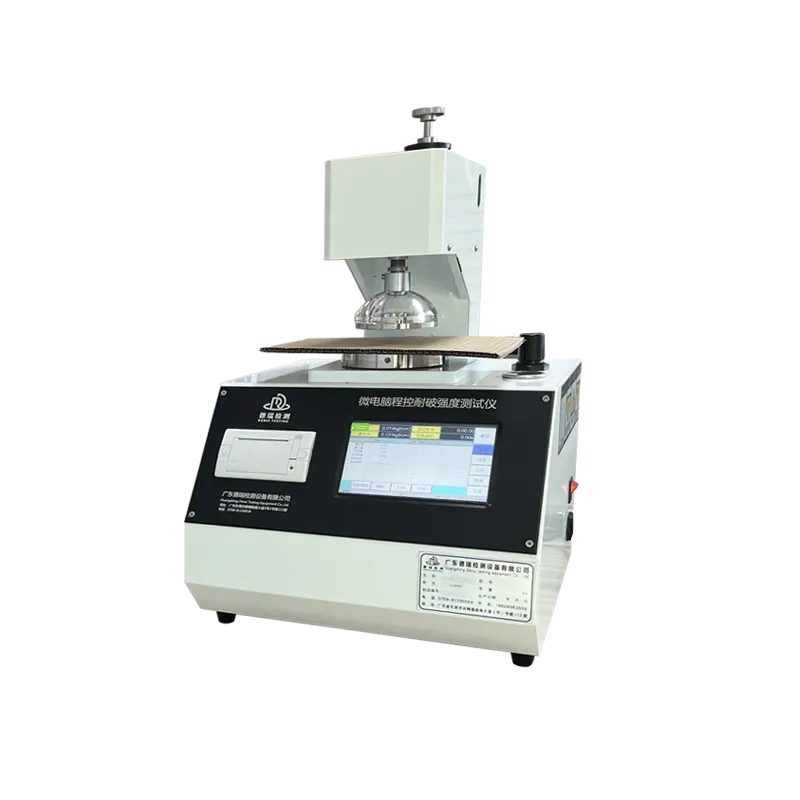

Derui’s Charpy pendulum impact tester is built with precision and durability in mind. It features a sturdy frame, a calibrated pendulum arm, a release mechanism, and a digital or analog display to measure absorbed energy accurately. The tester uses a hammer on a swinging pendulum to strike a notched specimen, breaking it to assess toughness.

Compared to other impact testers like the Izod test, the Charpy tester measures impact energy by striking the specimen in the middle with a pendulum swinging horizontally from the side, while Izod impacts the specimen held vertically from one end. This setup difference makes Charpy more commonly used for standard testing across metals, plastics, and alloys in industries throughout the U.S.

Principles of Operation

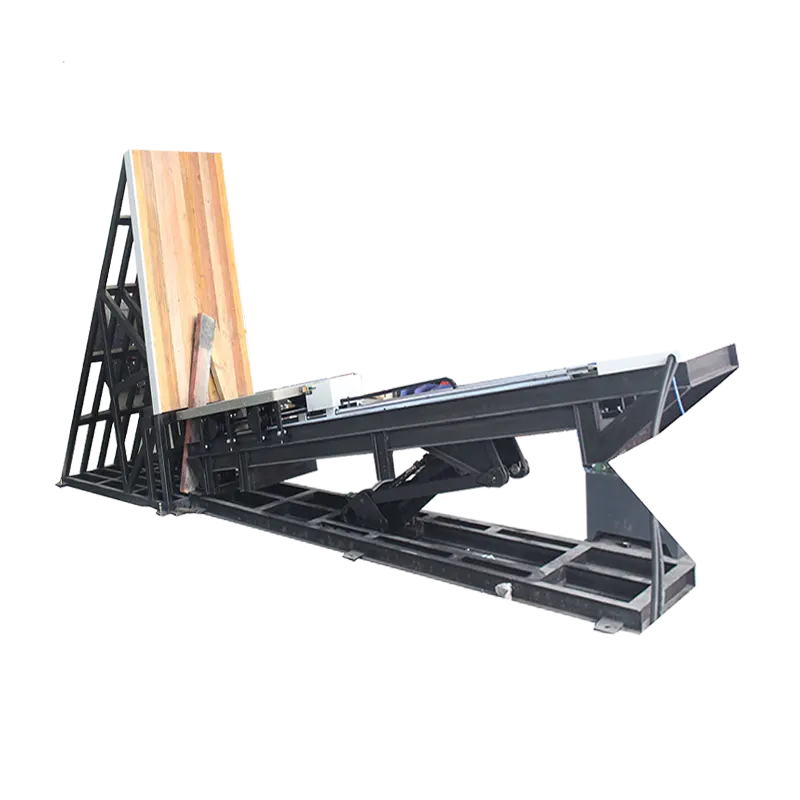

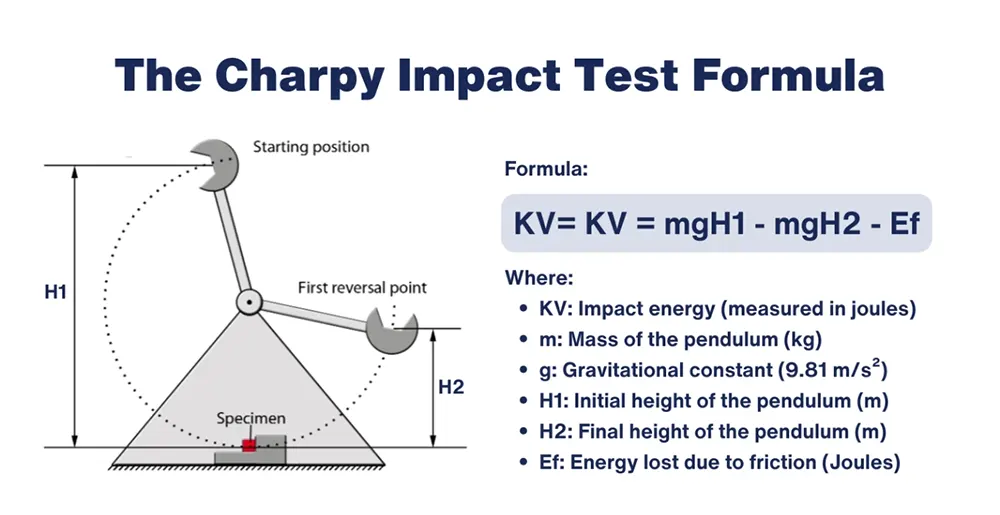

The Charpy pendulum impact tester works by swinging a weighted pendulum to strike a notched specimen. When the pendulum hits the sample, it breaks the material, and the energy absorbed by the specimen during the fracture is measured. This energy tells us how tough or impact-resistant the material is.

Here’s how it breaks down:

- The pendulum is lifted to a set height, giving it a known amount of potential energy.

- When released, the pendulum swings down and hits the specimen placed on supports.

- After breaking the sample, the pendulum continues to swing but at a lower height.

- The difference in height before and after striking is used to calculate the absorbed energy, which reflects the material’s impact toughness.

The size and shape of the test specimen play a big role in the results. Charpy test samples usually have a standardized notch—either V-notch or U-notch—that focuses the force at a specific point, making it easier to compare materials. The notch depth and width can influence how the material absorbs energy, so consistent specimen dimensions are key for accurate testing.

Understanding these basics helps ensure you get reliable data on material toughness, which is critical for applications where impact resistance matters.

Test Procedure Step by Step

Getting consistent and accurate results from a Charpy pendulum impact tester starts with following the right steps carefully.

Preparing and Positioning the Specimen

- Specimen size and notch: Use the standard specimen size, usually 10 x 10 x 55 mm with a V-notch or U-notch as per ASTM E23 or ISO 148.

- Clean the specimen: Remove any rust, dirt, or oil to avoid affecting the test results.

- Correct positioning: Place the specimen horizontally on the anvil supports, with the notch facing away from the pendulum’s striking edge. Make sure it’s centered securely without any movement.

Operating the Charpy Tester Safely

- Check that the machine is locked and the pendulum is held at the correct start height before release.

- Clear the area and ensure no one’s near the swinging path.

- Release the pendulum smoothly; avoid bumping or manual force to prevent false readings.

Reading and Interpreting Results

- After impact, the tester shows the absorbed energy—this measurement indicates the material’s impact toughness.

- Compare the energy value against material standards to decide if the specimen is ductile or brittle.

- Note the fracture surface; it can reveal if the failure was brittle or ductile for a deeper analysis.

Tips for Repeatability and Accuracy

- Use specimens from the same batch with identical preparation.

- Perform multiple tests and average the results to minimize errors.

- Regularly calibrate the tester to keep measurements reliable.

- Follow consistent test conditions like temperature and specimen alignment every time.

Following these simple steps helps you get precise, trustworthy impact toughness data for quality control and safety assurance.

Materials and Applications

The Charpy pendulum impact tester is used to check impact toughness across a wide range of materials. Most often, you’ll find it testing metals like steel, aluminum, and their alloys, as well as plastics used in engineering and manufacturing. This test helps determine how these materials behave under sudden impacts, which is critical in real-world conditions.

Several industries in the U.S. rely heavily on Charpy impact testing:

- Automotive: Ensuring metal parts withstand crashes or sudden hits without breaking.

- Aerospace: Testing alloys to meet strict safety and durability standards under extreme conditions.

- Construction: Verifying structural steel and materials resist impact, especially in seismic zones or harsh environments.

Real-life examples show how Charpy impact test results influence decisions. For instance, choosing a steel grade with higher absorbed energy can prevent brittle fracture in cold weather or high-stress situations. Plastics are also tested to make sure they won’t crack unexpectedly in automotive interiors or aerospace components. In all cases, this testing plays a key role in keeping products safe and reliable.

Standards and Compliance

Charpy pendulum impact testing follows strict international standards to ensure consistent and reliable results. The most common standards in the U.S. and worldwide are ASTM E23 and ISO 148. These standards define how to prepare the specimen, test conditions, and how to measure the absorbed energy during the impact test.

Derui’s Charpy impact test machines are built to fully comply with these standards. This means every test you run meets the exact criteria needed for accurate toughness testing and quality assurance. Compliance with ASTM E23 and ISO 148 ensures your test results are recognized professionally and legally across many industries.

To keep results reliable, Derui integrates precise calibration and high-quality materials into their testers. This focus guarantees the pendulum’s swing, energy measurement, and specimen positioning meet or exceed the standards. In addition, regular calibration services offered by Derui help maintain accuracy over time, giving you peace of mind with every test.

Advantages of Using Derui’s Charpy Pendulum Impact Tester

Derui’s Charpy Pendulum Impact Tester stands out thanks to precision engineering that guarantees reliable, consistent results every time. Built with durable materials and a robust design, it handles frequent use in busy U.S. labs and industrial settings without losing accuracy.

Key benefits include:

- Accurate Energy Measurement: The high-quality pendulum system ensures precise impact toughness readings, vital for quality control and safety checks.

- User-Friendly Operation: Clear controls and an intuitive setup make it easy for technicians to prepare specimens and run tests efficiently.

- Versatile Testing Capabilities: Compatible with various specimen sizes and notch types (V-notch, U-notch), meeting ASTM E23 and ISO 148 standards.

- Strong Support and Calibration Services: Derui offers professional calibration and regular maintenance support to keep your tester operating at peak accuracy.

Customers appreciate Derui’s reliable equipment for delivering consistent material toughness testing, helping them maintain high manufacturing standards. Many users highlight how easy it is to integrate the tester into their quality assurance workflows and trust the results for critical safety decisions.

Maintenance and Calibration Best Practices

Keeping your Charpy pendulum impact tester in top shape is key for reliable results. Here’s how to maintain and calibrate your equipment for long-term accuracy:

Routine Checks for Testing Accuracy

- Inspect the pendulum arm and hammer: Look for any signs of wear or damage that could affect swing consistency.

- Check the bearings and pivot points: Make sure they move smoothly without excessive play or noise.

- Verify the locking mechanism: Ensure it holds the pendulum securely before release to avoid misfires.

- Clean the machine regularly: Dust and debris can impact performance, especially around sensors and moving parts.

Tips for Long-Term Maintenance

- Lubricate moving parts with the recommended oils to reduce friction and wear.

- Check specimen supports and anvil condition to prevent uneven breaks. Replace worn parts promptly.

- Store the tester in a clean, dry environment to avoid rust or corrosion.

- Train operators on proper handling and calibration routines to avoid accidental damage.

Derui Calibration Services

To maintain ASTM E23 and ISO 148 compliance, regular professional calibration is essential. Derui offers:

- On-site calibration by trained technicians

- Traceable adjustment of energy scales and sensors

- Detailed calibration reports for quality audits

- Preventive maintenance plans to catch issues early

Following these best practices ensures your Charpy impact test machine delivers precise, consistent impact toughness data essential for material quality and safety in your projects.

Buying Guide How to Choose the Right Charpy Pendulum Impact Tester

Choosing the right Charpy pendulum impact tester is key to getting reliable results for your materials testing. Here’s what to keep in mind before making a purchase:

Key Factors to Consider

- Testing Capacity: Check the energy range (usually measured in Joules) to ensure it fits the toughness of the materials you test.

- Specimen Size Compatibility: Confirm the machine supports standard specimen sizes and notch types (V-notch or U-notch) per ASTM E23 or ISO 148.

- Software Integration: Look for models that include easy-to-use software for recording, analyzing, and saving test data, helping your QC process.

- Automation Level: Decide if you need a manual setup or semi-automatic/automatic testers for higher throughput and consistency.

- Accuracy and Calibration: Choose testers with certified calibration options to meet US standards and maintain testing integrity.

- Durability and Support: Invest in machines built for long-term use with good after-sales service and maintenance support from Derui.

Comparison of Derui Charpy Pendulum Impact Testers

| Model | Energy Range (J) | Specimen Size Support | Software Included | Automation Level | Calibration Support |

|---|---|---|---|---|---|

| Derui Basic | 300 | Standard ASTM/ISO | No | Manual | Optional |

| Derui Pro | 500 | Standard + Custom | Yes | Semi-automatic | Included |

| Derui Advanced | 600 | All standard types | Yes | Fully automatic | Included |

Consultation and Purchase Process

- Contact Derui Sales: Reach out for personalized advice based on your testing needs.

- Demo and Trial: Request demos or trial periods to see the tester in action.

- Customization: Discuss any special requirements such as custom specimen support or integration with your lab data systems.

- Order and Delivery: Work with Derui for smooth ordering, setup, and after-sales training.

Choosing wisely can save time and cost while improving your impact toughness testing accuracy in your lab or production line. Derui’s range offers options for every scale, from entry-level setups to high-end, automated testers made for industrial use.

Frequently Asked Questions FAQs

What is the main difference between Charpy and Izod impact tests?

Both measure impact toughness, but the Charpy pendulum impact tester strikes the specimen from behind its notch, while the Izod test hits it from the front. Charpy is more common for standard material toughness evaluations in the U.S.

How should I prepare Charpy impact test specimens?

Specimens usually have a standard size of 10mm x 10mm x 55mm with a V-notch or U-notch. They must be prepared precisely to meet ASTM E23 or ISO 148 standards for reliable results.

Can all materials be tested with a Charpy impact test machine?

Most metals, alloys, and some plastics fit well. Materials like composites may need specialized testing. The Charpy test is great for assessing ductile vs brittle fracture behavior.

What are common limitations of Charpy impact testing?

The test mainly measures notch toughness at specific temperatures and might not capture full material behavior under varied conditions. It’s not suitable for very thin or very small specimens.

How do I troubleshoot unusual test results?

Check specimen preparation first—incorrect notch or size can skew results. Also, verify the machine’s calibration and ensure consistent testing procedures.

What safety precautions should I follow during testing?

- Wear protective eyewear and gloves.

- Ensure the pendulum path is clear before release.

- Only trained personnel should operate the tester.

- Follow all facility safety protocols.

How often should the Charpy pendulum impact tester be calibrated?

Regular calibration is crucial—typically every 6 to 12 months, depending on usage. Calibration keeps energy measurement accurate and reliable.

Does the notch type affect impact toughness results?

Yes. V-notches are standard for most tests, but U-notches offer a different stress concentration affecting energy absorption. Choose based on your testing standard.

Can the Charpy impact test detect the ductile-to-brittle transition temperature?

Yes, by testing specimens at different temperatures, the Charpy test helps identify the temperature where materials change from ductile to brittle behavior—critical for safety in colder climates.

How do I ensure repeatability in my tests?

- Use consistent specimen preparation and positioning.

- Operate the machine the same way every time.

- Maintain regular calibration and maintenance.

If you have other questions about Charpy impact test methods, specimen size, or calibration services, feel free to reach out for detailed guidance.