What Is a Box Compression Tester Machine

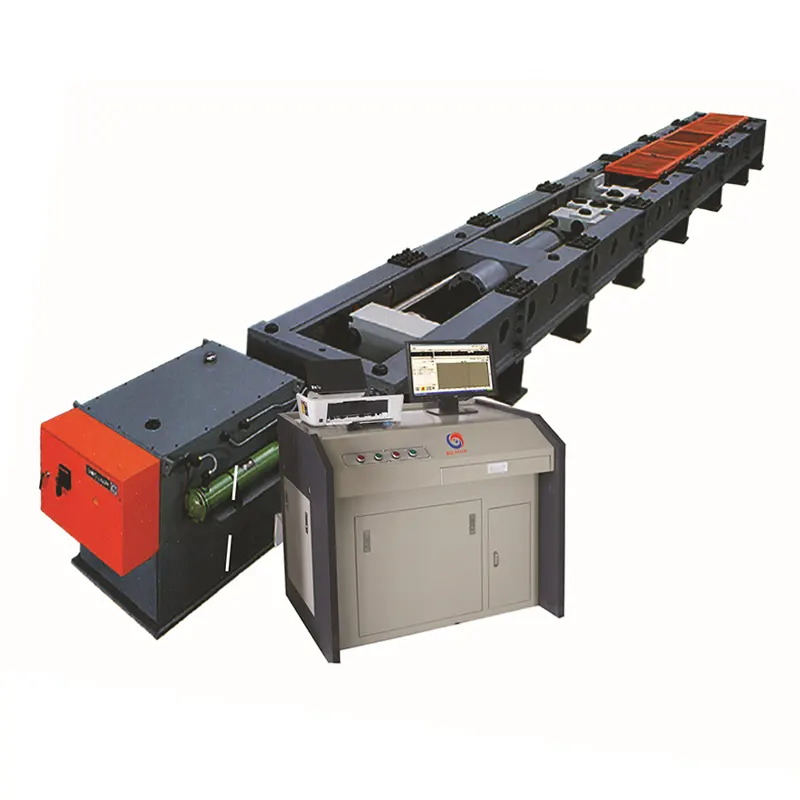

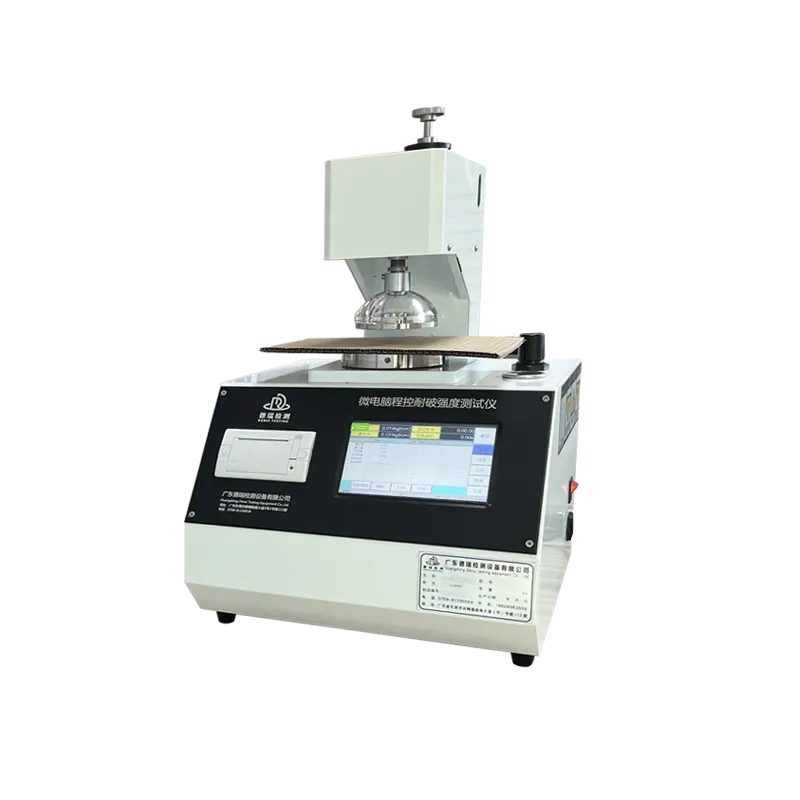

A box compression tester machine is a device designed to measure the strength and durability of packaging boxes, especially corrugated and cardboard boxes. Its main purpose is to simulate the pressure boxes face during stacking, shipping, and storage. By applying a controlled compressive force, the machine helps determine how much weight a box can withstand before it deforms or fails.

The compression testing process involves placing a box sample between two plates inside the tester. The machine gradually applies a load on the top plate, increasing pressure on the box until it crushes or reaches a set limit. This test provides vital data on the box’s compression strength, helping manufacturers and quality control teams evaluate packaging performance.

Key components of a box compression tester include:

- Load Frame – The sturdy structure supporting the compression plates.

- Compression Plates – Surfaces that press against the box to apply force.

- Load Cell – A sensor measuring the amount of force applied in real time.

- Control Panel – Interface to set test parameters and monitor progress.

- Data Output System – Software or display that records, analyzes, and presents test results clearly.

Together, these components make the box compression tester machine a critical tool for ensuring the reliability of packaging before products reach customers.

Importance of Box Compression Testing in Quality Control

Box compression testing plays a key role in making sure your packaging holds up under pressure. By measuring the strength and durability of corrugated boxes or cardboard packaging, this test helps prevent damage during storage and shipping. Knowing how much weight a box can withstand means fewer crushed products and happier customers.

Testing also helps you stay compliant with packaging standards like ASTM D642 and ISTA, which many retailers and shippers require. It’s a must for businesses in e-commerce, retail, and manufacturing where safe transportation and product protection are top priorities.

For example, an online retailer depends on box compression testers to verify cartons won’t crush during long-distance shipping. Manufacturers use these machines to ensure their packaging keeps products safe on warehouse shelves stacked high. Across industries, box compression testing keeps your packaging reliable and your products intact.

Types of Box Compression Tester Machines

When it comes to box compression tester machines, you have three main types to choose from, each suited for different needs and budgets.

Manual Box Compression Testers

- Operation: Hand-operated, simple to use

- Best For: Small businesses, low testing volume

- Advantages: Affordable, easy maintenance

- Limitations: Slower testing, less consistent results

Semi-Automatic Box Compression Testers

- Operation: Combines manual setup with automated testing

- Best For: Medium-sized operations

- Advantages: Faster than manual, better accuracy

- Limitations: Higher cost, some operator input still needed

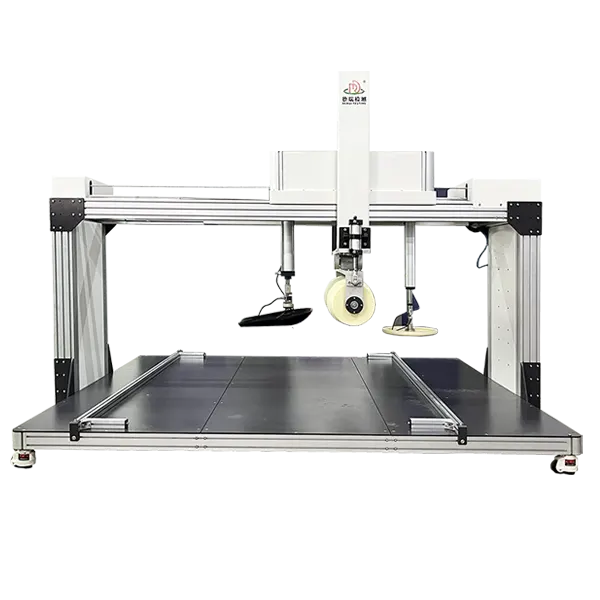

Fully Automatic Box Compression Testers

- Operation: Fully automated testing from start to finish

- Best For: Large-scale production and labs

- Advantages: High accuracy, fast test cycles, integrated data reporting

- Limitations: Higher price, complex setup

Comparison Table

| Feature | Manual Tester | Semi-Automatic Tester | Fully Automatic Tester |

|---|---|---|---|

| Ease of Use | Simple | Moderate | Advanced |

| Speed | Slow | Moderate | Fast |

| Accuracy | Basic | Good | High |

| Price | Low | Medium | High |

| Maintenance | Low | Moderate | Requires Skilled Tech |

| Typical Users | Small businesses | Mid-sized facilities | Large manufacturers & labs |

Choosing the right box compression tester depends on your testing frequency, budget, and the level of precision you need. This breakdown helps you match your business needs with the best machine type.

Key Features to Look for in a Box Compression Tester Machine

When choosing a box compression tester machine, keep in mind these important features to ensure you get reliable and efficient testing for your packaging:

| Feature | What to Look For |

|---|---|

| Load Capacity and Range | Must handle your box sizes and expected compression forces, usually from a few pounds up to several thousand pounds. |

| Accuracy and Resolution | Precise measurements are key for trustable results. Look for testers with high resolution to catch small differences in strength. |

| Test Speed and Cycle Time | Faster tests mean more boxes tested per day. Balance speed with accuracy to keep workflows smooth. |

| User Interface and Software Integration | Easy controls and clear displays help reduce errors. Software that integrates with your QC system streamlines data management. |

| Data Analysis and Reporting | Ability to record, analyze, and export test results is crucial for quality control and compliance documentation. Look for customizable reports. |

| Durability and Maintenance | A sturdy machine built for daily use reduces downtime. Consider machines that require minimal upkeep and offer easy access for maintenance. |

These features ensure your carton box testing machine fits your business needs in production scale, accuracy, and ease of use—key for keeping up with packaging quality demands in the US market.

How to Choose the Right Box Compression Tester Machine for Your Business

Picking the best box compression tester machine depends on a few important factors. Here’s what you need to consider to make a smart choice:

Assess Your Testing Needs

- Box Sizes and Types: Make sure the tester handles the range of box sizes and materials you use, whether corrugated, cardboard, or custom cartons.

- Test Requirements: Consider if you need basic compression strength or more advanced tests like stacking or transport package integrity.

Budget Considerations

- Machines vary widely in price from manual testers to fully automated systems.

- Decide how much you want to invest upfront versus long-term cost savings from automation and faster tests.

Frequency of Use and Production Scale

| Usage Level | Recommended Machine Type |

|---|---|

| Low (spot checks) | Manual or semi-automatic tester |

| Medium (routine QC) | Semi-automatic compression tester |

| High (continuous) | Fully automatic box compression tester |

After-Sales Support and Warranty

- Choose brands with strong US-based customer support.

- Look for extended warranties and quick service to minimize downtime.

Compatibility With Packaging Standards

- Ensure the machine complies with ASTM D642, ISTA, or other relevant US and international standards.

- This guarantees your packaging meets industry requirements and shipping safety.

By matching these factors with your business needs, you’ll find a box compression test machine that boosts quality control and protects your products during transit.

Benefits of Using Derui Box Compression Tester Machines

Derui box compression tester machines offer several clear advantages for businesses focused on packaging quality and durability.

Advanced Technology and Precision

- Uses cutting-edge sensors for accurate compression strength tests

- Delivers consistent and reliable results, crucial for quality control

Industry Compliance and Certifications

- Meets ASTM D642 and ISTA standards for package compression resistance

- Ensures your testing aligns with US and international packaging regulations

User-Friendly Design and Software

- Intuitive interface simplifies test setup and operation

- Software provides easy data analysis, load-deformation curves, and detailed reports

Robust Build for Long-Term Use

- Sturdy frames and components stand up to heavy daily use

- Low maintenance needs reduce downtime and costs

Customer Support and Customization

- Responsive US-based customer service for quick help and advice

- Custom options available to fit specific packaging types or test requirements

| Feature | Benefit |

|---|---|

| State-of-the-art Sensors | High precision and repeatability |

| Certified Compliance | Meets ASTM and ISTA standards |

| Software Integration | Easy data handling and reporting |

| Durable Construction | Reliable performance over time |

| US-Based Support | Fast assistance and tailored solutions |

Choosing Derui means getting a reliable, precise box crush tester machine that supports your packaging quality goals with ease.

Step by Step Guide to Using a Box Compression Tester Machine

Using a box compression tester machine is straightforward when you follow these key steps:

Preparing the Box Sample

- Choose a representative sample box that reflects your typical packaging.

- Make sure the box is fully assembled and sealed as it would be in real use.

- Remove any cushioning or contents to test the box strength alone, unless testing finished packaging.

Setting the Parameters

- Input the box dimensions into the machine — length, width, and height.

- Set the desired load capacity based on the box material and expected limits.

- Choose the test speed or compression rate, usually preset for standard testing.

- Select any required test programs or protocols, such as ASTM D642 or ISTA standards.

Running the Test

- Place the box sample carefully between the compression plates.

- Start the test, allowing the machine to apply pressure steadily and record data.

- The machine compresses the box until it reaches failure or the set limit.

- Wait for the test to complete and for the machine to release pressure automatically.

Interpreting the Results

- Review the load-deformation curve and maximum load recorded.

- Compare results against your quality control standards or industry benchmarks.

- Identify weak points or inconsistencies in box strength.

- Save or export the data for records and reporting.

Tips for Accurate and Consistent Testing

- Always use well-prepared, standard samples to avoid skewed results.

- Calibrate your box crush tester machine regularly for accuracy.

- Perform multiple tests to ensure consistency and spot any outliers.

- Keep the testing environment stable — avoid extreme temperatures or humidity.

- Follow manufacturer guidelines on test speed and load application.

Following these steps helps you get reliable and useful data from your box compression tester machine, making sure your packaging holds up in the real world.

Maintenance and Troubleshooting Tips

Keeping your box compression tester machine in good shape is key to accurate, reliable results. Here’s a quick routine maintenance checklist and troubleshooting guide tailored for US businesses using carton box testing machines.

Routine Maintenance Checklist

- Clean the machine regularly: Wipe down plates and sensors to avoid dust buildup that affects test accuracy.

- Lubricate moving parts: Apply manufacturer-recommended lubricants to ensure smooth operation.

- Check calibration: Verify calibration regularly to maintain precision—most systems need checking every 6 months or after heavy use.

- Inspect electrical connections: Look for loose wires or faulty cables to prevent unexpected shutdowns.

- Review software updates: Keep the user interface and data analysis software up to date for best performance.

- Store properly: Avoid extreme temperatures or humidity in the testing area to protect sensitive components.

Common Issues and Solutions

- Inconsistent test results

- Cause: Dirty sensors or worn load cells

- Fix: Clean sensors and recalibrate or replace load cells

- Machine won’t start or power failure

- Cause: Faulty wiring or blown fuse

- Fix: Inspect wiring, replace fuses, or contact technician

- Error messages during testing

- Cause: Software or hardware glitches

- Fix: Restart machine, update software, or reset system settings

- Slow or jerky compression cycle

- Cause: Lack of lubrication or mechanical wear

- Fix: Lubricate moving parts or schedule maintenance service

When to Contact Professional Support

- Calibration checks fail after repeated attempts

- Mechanical parts show signs of damage or unusual noise

- Persistent electrical faults or software errors

- Upgrading or installing new software features

- Need assistance for operator training or system customization

Consistent maintenance and quick troubleshooting mean less downtime and better testing accuracy. If you’re unsure or face complex issues, reaching out to your box compression tester machine’s manufacturer or a certified service provider is always the safest bet.