Explore the advanced Battery Crush & Nail Penetration Test Chamber designed to ensure the durability and safety of battery systems through rigorous testing methodologies.

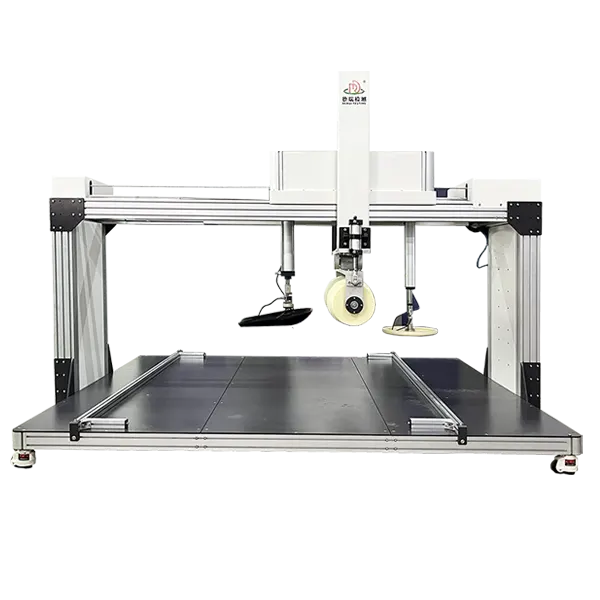

Introduction to Battery Needle Puncture and Compression Testing Machine

- Application: Simulate the situation where various power lithium battery electrodes are compressed during use, and artificially present the different conditions that may occur when the battery is compressed.

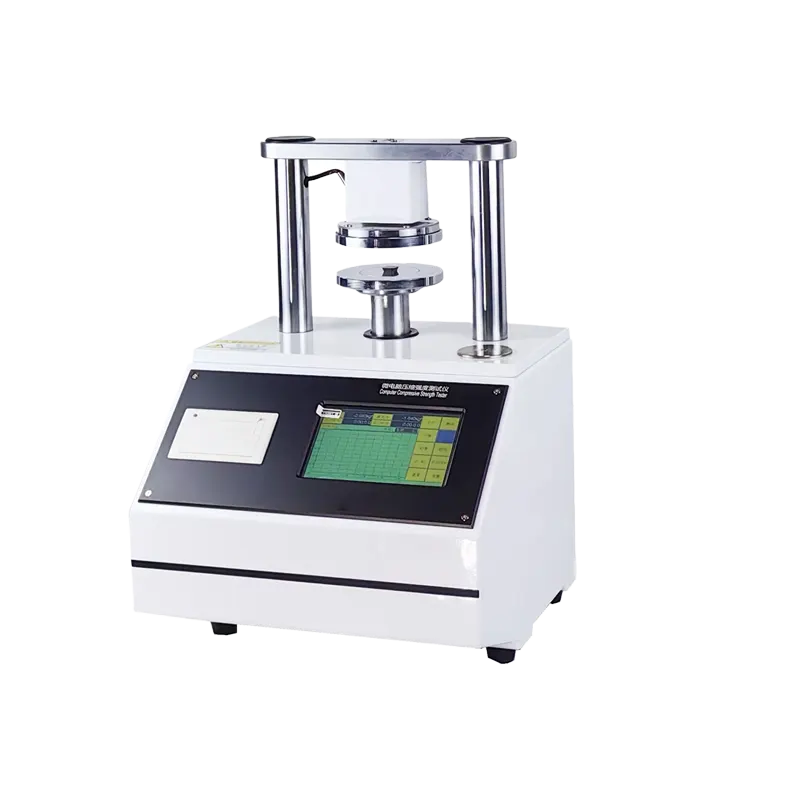

- Principle: Place the battery between two squeezing plates and apply pressure to the squeezed battery. Once the maximum pressure is reached, it will automatically return to its original position.

Structural features

- Box material: The inner box is often made of stainless steel plate, 3mm thick 45# steel plate with chrome plating and Teflon coating, etc. The outer box is made of cold-rolled steel plate with baked paint.

- Observation window: It is equipped with explosion-proof glass observation Windows, and some are also provided with explosion-proof nets and high-brightness energy-saving lighting lamps.

- Exhaust port: The rear part of the box is equipped with an exhaust fan and a reserved interface for the exhaust duct.

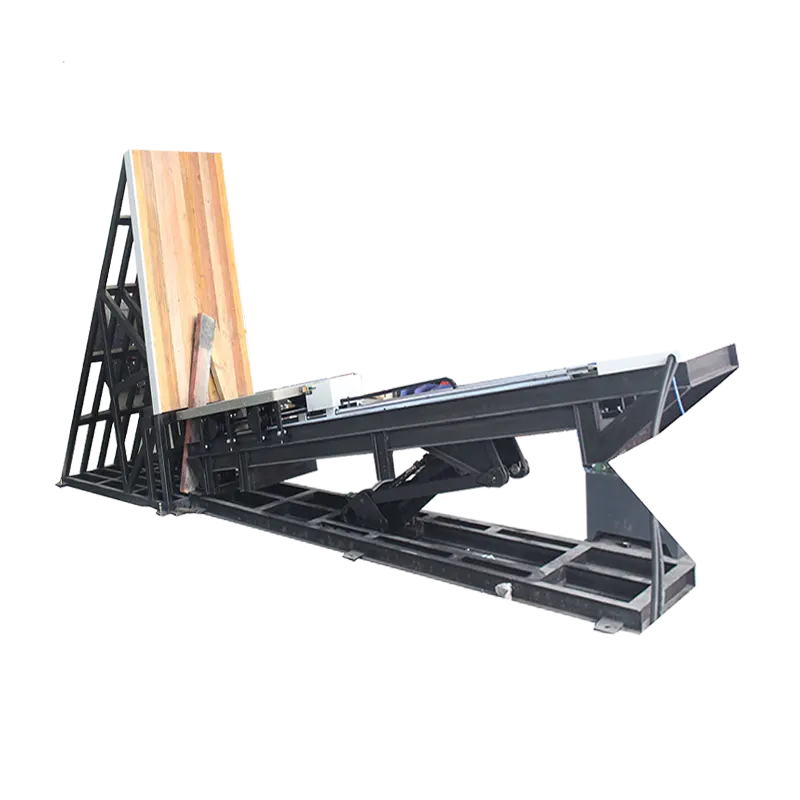

- Box door: Part of it is automatically lifted and lowered by a motor driven by a precision ball screw, and there is a door limit switch that cuts off power when opened.

- Test holes: There are test holes on both the left and right sides, which facilitate the insertion of temperature, voltage and current acquisition wires.

Impact satisfaction standard

UL1642 "Mechanical Tests - Impact Tests in Lithium Battery Standards"

2.UL2054-2005 "Mechanical Tests - Impact Tests in Battery Standards"

3.UN38.3 "Standard Regulations for Testing Lithium Batteries and Battery Packs - Impact Tests"

4.GB/T 18287-2013 "General Specification for Lithium-ion Batteries for Cellular Use - Load Impact Test"

5.SJ/T 11169-1998 "Lithium Battery Standard - Impact Test"

6.YD 1268-2003 "Safety Requirements for Batteries and Chargers of Mobile Communication Handheld Devices - Impact Test"

Steel needle for puncture test

A: 2 high-temperature quenched tungsten steel needles of φ3mm to φ10mm each (the length of the steel needles of φ3mm to φ5mm is 100mm; The length of steel needles with diameters ranging from φ6mm to φ7mm is 200mm. The lengths of the φ8mm steel needles are 200mm and 400mm. Steel pins with diameters ranging from φ9mm to φ10mm are 400mm and 600mm in length.

B: One high-temperature resistant white steel needle each of φ3mm to φ10mm (the length of the steel needle from φ3mm to φ5mm is 100mm; The length of steel needles with diameters ranging from φ6mm to φ7mm is 200mm. The lengths of the φ8mm steel needles are 200mm and 400mm. Steel pins with diameters ranging from φ9mm to φ10mm are 400mm and 600mm in length.

Safety protection system

- Overvoltage protection: The sensor is pre-set with a pressure range, effectively preventing excessive squeezing force from damaging the sensor and the drive motor.

- Under-phase and reverse phase protection switch;

- Travel limit protection

- Overcurrent protection for line fuses

- Overload protection

Factory configuration list of equipment

- Testing machine mainframe: 1 set

- Standard needle-punched extruded pressure plates: 1 set each

- Product Manual (including PLC User Manual)