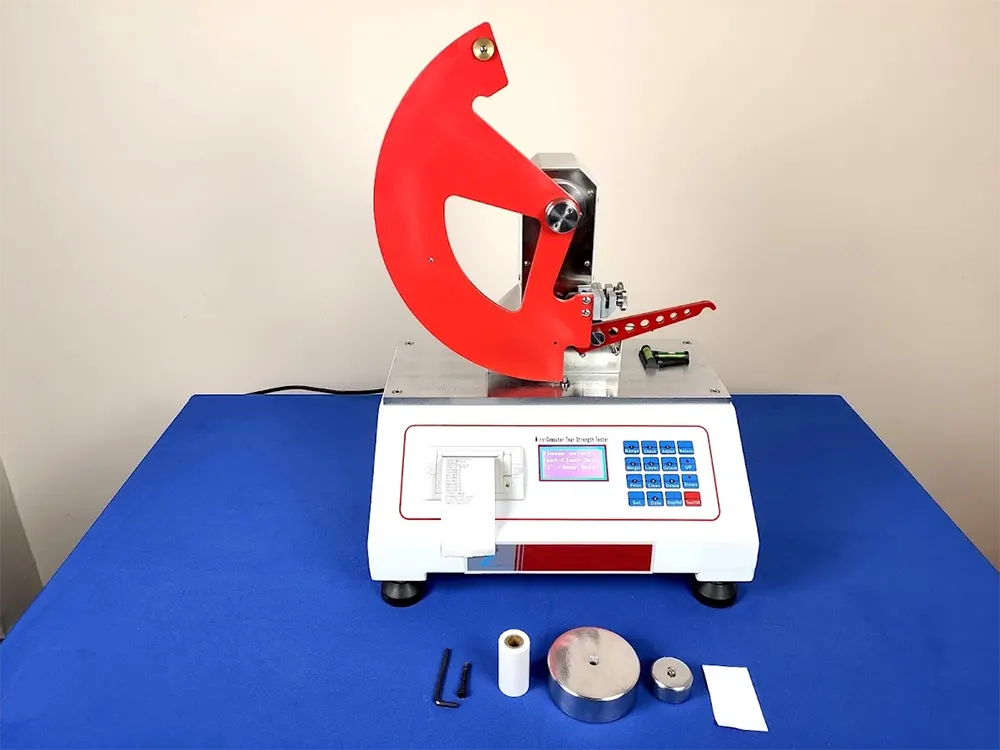

What is a Tear Strength Test Machine

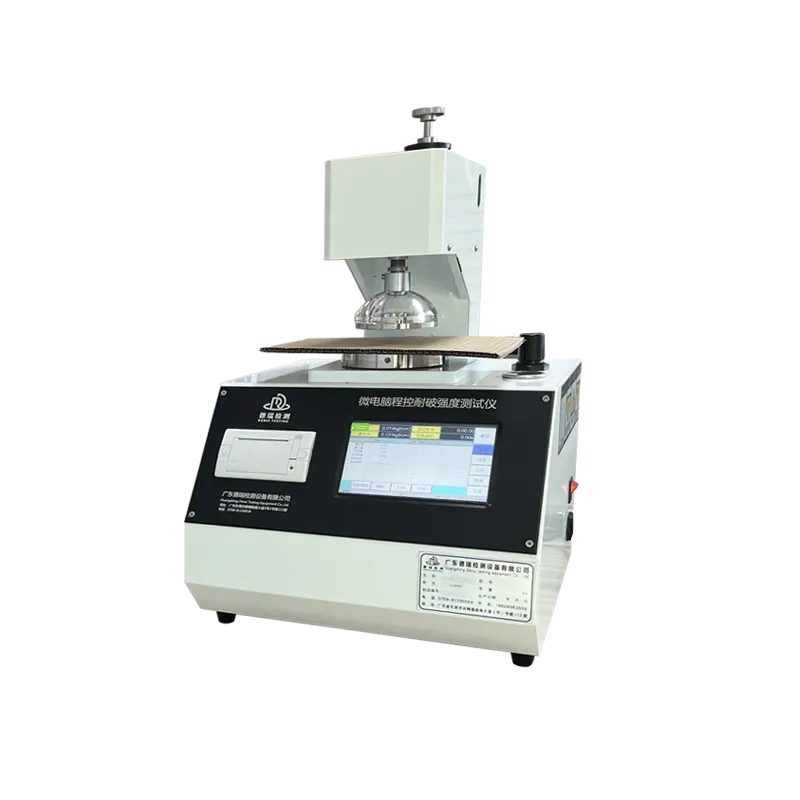

A tear strength test machine is a device used to measure how much force is needed to start or continue tearing a material. It’s essential for assessing the durability and quality of products made from textiles, plastics, rubber, paper, and more.

How It Works

The machine holds a sample securely, then applies force until the material tears. It measures key parameters like:

- Tear Strength: The force required to propagate a tear.

- Elongation: How much the material stretches before tearing.

- Tear Resistance: Material’s ability to resist tearing under stress.

Types of Tear Strength Tests

Different tests help analyze materials in varied ways depending on end use. Common test types include:

| Test Type | Description |

|---|---|

| Trouser Tear | Tests tear resistance using a slit in the sample shaped like trouser legs. |

| Tongue Tear | Measures tear force on materials using a tongue-shaped cut. |

| Angle Tear | Evaluates tear resistance under a specific angle, commonly 90°. |

| Elmendorf Tear | Uses a pendulum to measure tear strength quickly and accurately. |

Each test fits different material types and industry requirements, helping manufacturers ensure quality and safety.

How Does a Tear Strength Test Machine Work

Using a tear strength test machine is pretty straightforward. Here’s the basic step-by-step process:

- Prepare the sample – Cut your material (like fabric, plastic, or paper) into the right shape and size, depending on the tear test type you’re running (trouser tear, tongue tear, etc.).

- Secure the sample – Place it in the machine’s clamps or grips. These hold the sample firmly without damaging it.

- Start the test – The machine pulls apart the material at a steady speed.

- Measure the force – Load cells inside the machine record how much force it takes to tear the sample.

- Record results – Data like tear strength, force at break, and elongation get shown on the display unit or saved for analysis.

Key Components of a Tear Strength Test Machine

- Clamps/Grips: Hold the material in place during testing.

- Load Cells: Sensors that measure the force applied to tear the sample.

- Display Unit: Shows real-time results and lets you control test settings.

- Motor and Control System: Drives the pulling action at a set speed.

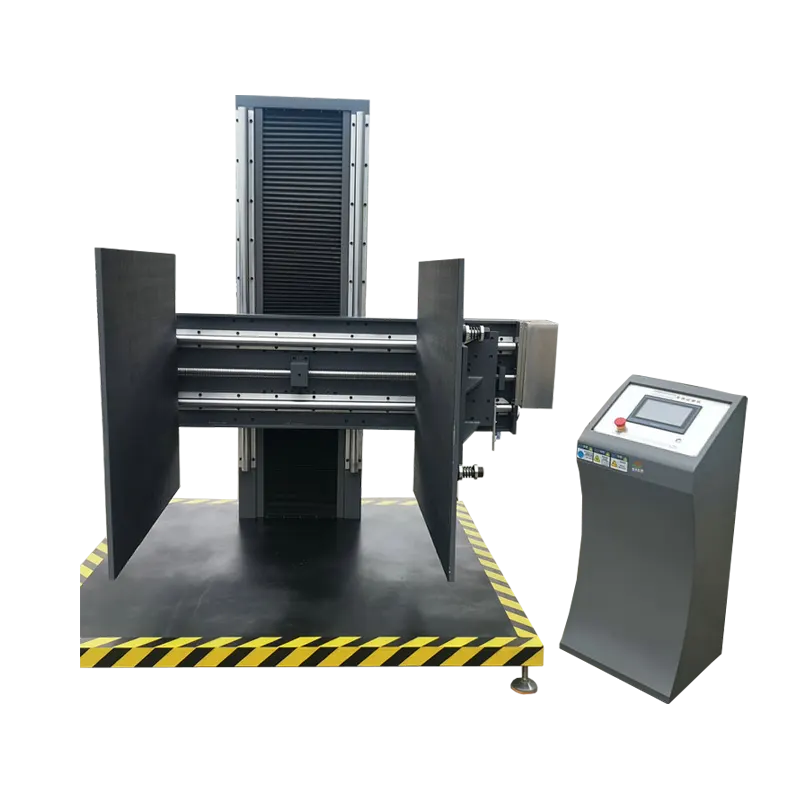

Digital vs Manual Tear Strength Test Machines

Digital testers automate the process. They provide accurate, real-time readings, save data digitally, and often comply with ASTM and ISO standards. They’re easier to use and great for repeated tests but come with a higher price.

Manual machines rely on mechanical parts and often require you to read force values from a dial or gauge. They’re simpler and usually less costly but less precise and slower for data recording.

Applications of Tear Strength Testing

Tear strength testing plays a crucial role across many industries where material durability matters. It helps manufacturers verify the quality and reliability of their products before they hit the market.

Industries That Benefit

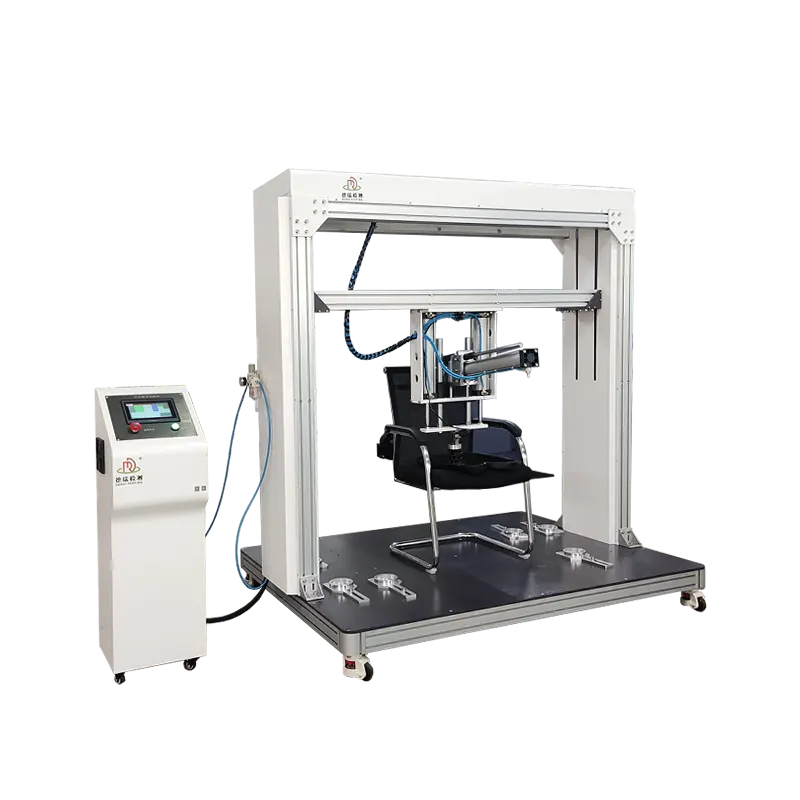

- Textiles: Ensures fabrics used in clothing, upholstery, and industrial textiles resist tearing during use.

- Packaging: Tests films, bags, and cartons for tear resistance to protect products and improve shelf life.

- Rubber and Plastics: Confirms the strength of seals, gaskets, and molded parts to prevent failures.

- Paper: Measures tear resistance in printing papers, cardboard, and specialty papers for durability.

- Automotive: Checks interior materials like seat covers and door panels that face daily wear and tear.

- Footwear: Verifies leather, synthetic fabrics, and soles to withstand regular stress and usage.

Real-World Examples

- A leading packaging company used tear strength testing machines to improve their plastic film, reducing product damage by 30% during shipping.

- Automotive suppliers rely on tear strength testers to maintain consistent quality in airbags and upholstery, ensuring safety and comfort.

- Footwear brands employ textile tear resistance machines to guarantee their shoes last longer, providing better value to customers.

Tear strength testing is essential in making sure products perform reliably and meet the high standards expected in the US market. It helps avoid costly recalls and boosts customer confidence.

Key Features to Look For in a Tear Strength Test Machine

Choosing the right tear strength test machine means focusing on features that match your testing needs and industry standards. Here’s what to keep an eye on:

Precision and Accuracy Standards

Your machine should meet recognized standards like ASTM and ISO. These ensure consistent, reliable results when measuring tear strength, elongation, and force.

Load Capacity and Measurement Range

Make sure the tester can handle the materials you work with—whether thin films or tougher textiles. Check both the maximum load and the smallest measurable force.

| Feature | Recommended Range |

|---|---|

| Load Capacity | 10 N to 5,000 N (depending on material) |

| Measurement Accuracy | ±0.5% or better |

Ease of Use and Automation

Look for user-friendly controls and clear displays. Automated grips and sample handling speed up testing and reduce errors. The faster and simpler the setup, the more efficient your lab becomes.

Data Recording and Connectivity

Modern tear resistance testing machines offer digital data logging with export options (USB, Wi-Fi, or Bluetooth). This helps you track results, create reports, and keep records easily for quality control.

Durability and Maintenance

A rugged frame and quality components keep the machine running longer with minimal downtime. Also, check for straightforward maintenance routines and availability of local service support to avoid disruptions.

Why Choose Derui Tear Strength Test Machines

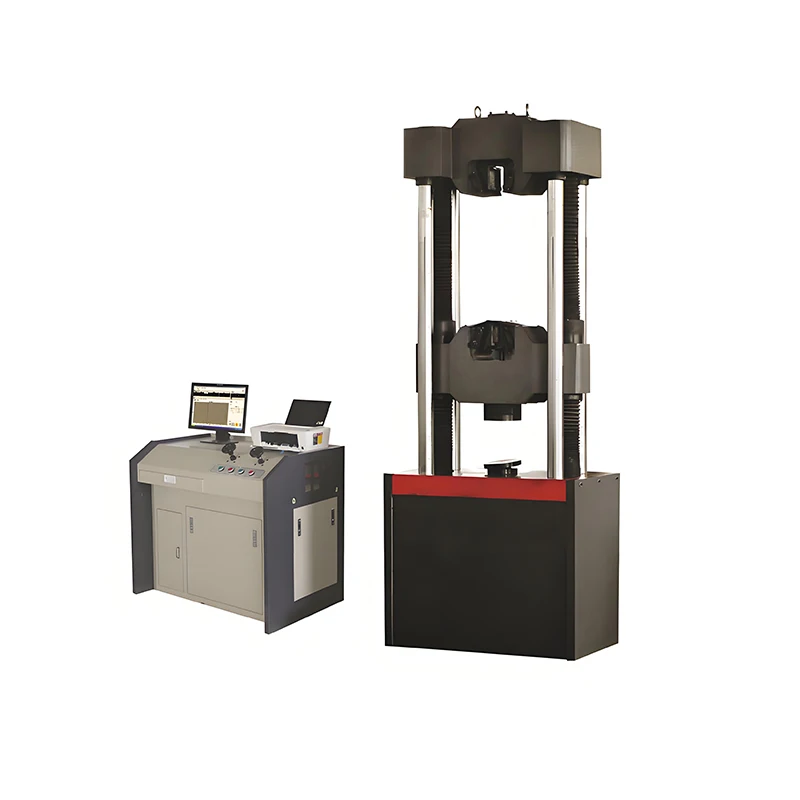

Derui offers a wide range of tear strength test machines designed to meet the needs of various industries in the United States. Whether you’re in textiles, packaging, rubber, or plastics, Derui has models tailored for all common tear resistance testing needs, including ASTM tear strength testers and digital tear strength testers.

Derui Product Line Overview

- Digital Tear Strength Testers: High precision, user-friendly interfaces, ideal for automated labs.

- Manual Tear Test Machines: Budget-friendly, reliable for quick testing with basic features.

- Specialized Testers: Machines designed for textiles, paper, film, and rubber tear resistance.

Unique Selling Points

| Feature | Description |

|---|---|

| Innovation | Latest sensor technology and software integration for precise results. |

| Reliability | Durable builds ensure consistent, repeatable tear strength measurement. |

| Standards Compliance | Fully compliant with ASTM, ISO, and other international tear testing standards. |

Customer Success Stories

Users across the U.S. praise Derui machines for:

- Improving product quality control.

- Simplifying tear strength testing workflows.

- Delivering accurate data that supports product development.

After Sales Support and Calibration

Derui provides:

- Prompt technical support and troubleshooting.

- Routine calibration services to keep your tear strength machine accurate.

- Maintenance guidance to extend machine lifespan.

Choosing Derui means you get reliable tear strength testers backed by expert service and ongoing support tailored to U.S. market demands.

How to Select the Right Tear Strength Test Machine for Your Needs

Choosing the right tear strength test machine depends a lot on what industry you’re in and the materials you work with. For example, if you’re testing textiles, you might need a machine designed for fabric tear resistance, like a textile tear strength machine. For plastics or rubber, look for a rubber tear strength tester or a plastic film tear strength device that can handle those materials.

Keep these key factors in mind:

- Material Type: Different materials need specific clamps, grips, and force ranges. Make sure the machine supports the tear test type you need, whether it’s trouser tear, tongue tear, or angle tear.

- Industry Standards: Check if the machine complies with ASTM or ISO tear strength testing standards, ensuring your tests are accurate and recognized.

- Load Capacity & Range: Match the machine’s force measurement range to your material’s expected tear strength. Don’t overspend on a too-powerful machine if you’re only testing thin films or paper.

- Budget vs Long-Term Value: A higher upfront cost might seem steep, but a machine with better durability, precision, and support often saves money in the long run by reducing downtime and recalibration needs.

- Digital Features and Automation: If you want easier data tracking, consider a digital tear strength tester with connectivity options or automated reporting—this can be a big time-saver.

- Customization and Expert Advice: Derui offers tailored solutions to fit your exact needs. Consulting with their experts can help you get the right specs, grips, and calibration options for your materials and test methods.

Talking directly with Derui specialists ensures you pick a tear strength test machine that fits your material types, testing methods, and budget while offering reliable performance down the line.

Tips for Maintaining and Calibrating Your Tear Strength Test Machine

Keeping your tear strength test machine in top shape is key to getting accurate, reliable results every time. Here’s a simple routine maintenance checklist to help:

- Clean the machine regularly to remove dust, debris, and residue from samples.

- Check clamps and grips for wear and tear; replace them if they’re damaged.

- Inspect load cells and sensors for any signs of malfunction.

- Lubricate moving parts as recommended in the user manual.

- Ensure the display unit and controls are functioning properly.

Periodic calibration is just as important. It ensures your tear resistance testing machine measures force and elongation correctly, aligning with standards like ASTM and ISO. Without calibration, results can drift over time, leading to unreliable data and potential quality issues.

Derui offers professional calibration services tailored to maintain your machine’s precision. Their expert support includes:

- On-site and off-site calibration options.

- Compliance with international testing standards.

- Prompt service to minimize downtime.

- Technical support and consultation to optimize your equipment’s performance.

Regular maintenance combined with expert calibration keeps your tear strength test machine running smoothly, delivering precise results for your material testing needs.

Frequently Asked Questions FAQs

What is the best way to operate a tear strength test machine?

Start by preparing your sample according to the test method (like ASTM or ISO), then securely clamp it in the grips. Follow the machine’s prompts to begin the test. Always ensure the machine is calibrated and grips are clean to avoid errors.

How often should I calibrate my tear strength tester?

Calibration depends on usage but typically every 6 to 12 months is recommended. Regular calibration keeps your data precise and helps meet industry standards like ASTM D1922 or ISO 6383.

What maintenance does a tear resistance testing machine need?

Keep the grips and clamps clean, check for wear and tear on moving parts, and update software if you have a digital tester. Avoid exposure to dust or moisture to prolong the machine’s life.

What are common troubleshooting tips?

If results are inconsistent, check sample alignment and grip tightness. Make sure load cells are functioning correctly. If digital displays freeze or misread, reboot the system or contact support.

Can a digital tear test machine replace a manual one?

Yes, digital models offer higher precision, easier data recording, and faster tests. But manual testers are simpler and great for basic or low-volume testing.

Which standards do these machines follow?

Most tear strength test machines comply with standards like ASTM D1922 for textiles or ISO 6383 for plastics and films. Always choose a tester that meets your industry’s specific requirements.

How do I choose the right tear strength test machine?

Consider your material type, testing volume, accuracy needs, and budget. Consult with specialists to find a machine that fits your application perfectly.

If you have more questions or need support, our Derui team is ready to help!