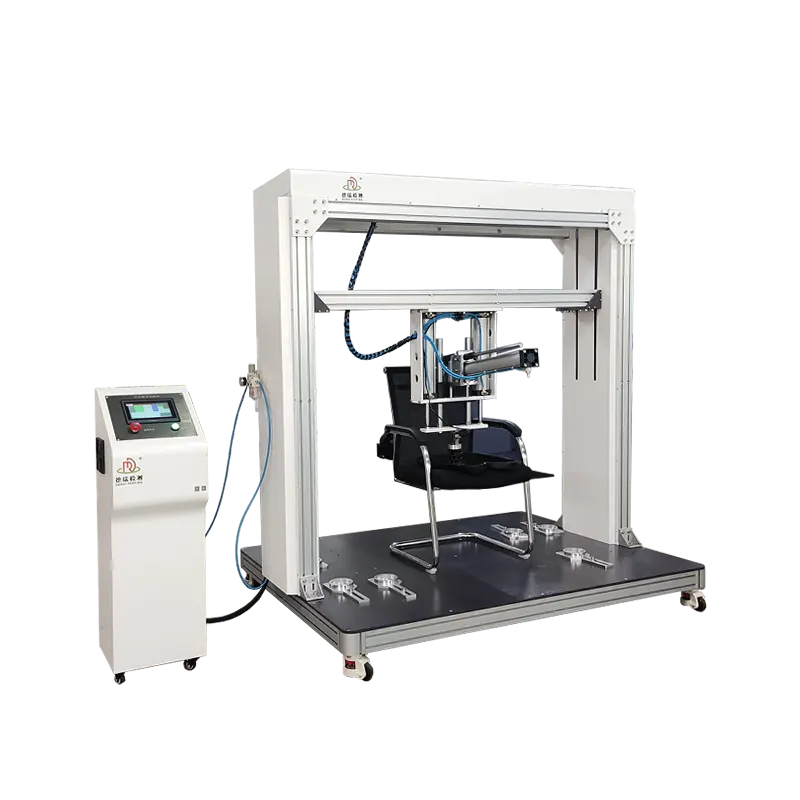

The armrest durability testing machine is used to test the durability of office chair armrests under the action of cyclic side pressure (at a 10-degree angle to the vertical). The chair is fixed on the test table, and the force application fixture is adjusted to the appropriate position. It is suitable for testing armrests, seat surfaces, footrests, etc. This equipment is a multi-functional testing device that can achieve various testing functions by adjusting the direction of the force output by the cylinder.

Our seat armrest durability testing machine is specifically designed to accurately assess and enhance the durability of seats. It features a user-friendly operation interface and high-precision measurement functions, enabling you to conduct tests more quickly and improve work efficiency. The equipment supports multiple testing standards and can be applied to various materials, ensuring that your seat products meet all quality requirements. We recommend that you take advantage of these outstanding features to achieve higher quality standards for your seat products.

Furniture inspection scope:

1、Panel furniture: writing desks, dining tables and chairs, beds, children's beds and folding cots, etc.

2、Soft furniture: spring soft mattresses, elastic mattresses made of palm fiber, sofas, etc.

3、Office furniture: visitor chairs, conference tables, swivel chairs, staff chairs, computer desks, executive desks, executive chairs, screens, etc.

4、Outdoor furniture: beach chairs, folding chairs, lounge chairs, folding beds, garden armchairs, garden tables, bar counters, etc.

Product Features:

The design of the seat armrest durability testing machine needs to meet the requirements of multiple scenarios, high precision, and ease of operation, etc. Its main features include:

- Multi-mode load simulation, covering real usage conditions

It can simulate various force application forms in actual use, such as vertical pressing (simulating arm support or tapping), horizontal friction (simulating hand sliding), twisting (simulating armrest rotation adjustment), etc. It supports single mode or combination mode testing to comprehensively evaluate the comprehensive durability of armrests. Some high-end models can adjust the load type (such as constant load, alternating load, pulse load) to meet the testing requirements of different standards (such as car seats, office chairs, furniture armrests, etc.). - High-precision control and data feedback

It adopts a combination of servo motors/cylinders and precision sensors (force sensors, displacement sensors) to achieve precise control of load application (accuracy up to ±0.5% FS), ensuring stable and consistent parameters such as force value, speed, and displacement in each test. Real-time test data (such as load curves, displacement changes, cycle counts) are collected and reports are generated through the software system (supporting Excel/PDF formats) for easy analysis of the fatigue limit and failure modes of armrests. - Modular design, adaptable to various types of armrests

The fixture system adopts a replaceable modular design. By adjusting the shape (such as arc, plane, grooved, etc.) and size of the fixture, it can adapt to armrests of different shapes and sizes (such as car seat arc armrests, office chair square armrests, sofa wooden/leather armrests), enhancing the versatility of the equipment. Some models support quick clamping mechanisms (such as pneumatic grippers, magnetic fixation) to shorten sample change time and improve testing efficiency. - Automated operation and safety protection

It supports presetting test parameters (such as cycle count, load size, frequency) to achieve one-click fully automatic testing, reducing manual intervention and operational errors. It is equipped with multiple safety protection functions, such as overload protection (automatic shutdown when exceeding preset force value), emergency stop button, armrest displacement limit alarm, etc., to prevent equipment damage or accidental injury from sample ejection. - Durability and ease of maintenance

Key components (such as motors, sensors, transmission mechanisms) are made of high-strength materials (such as stainless steel, aluminum alloy) and coated with wear-resistant coatings to withstand long-term high-frequency testing. Moving parts (such as guide rails, lead screws) are designed for regular lubrication to extend service life. The equipment structure is open, facilitating daily cleaning and maintenance (such as sensor calibration, fixture replacement), reducing long-term usage costs.

Structural Composition:

The structure of a seat armrest durability testing machine is typically composed of five major modules: "loading system", "clamping system", "control system", "support frame", and "auxiliary devices". These modules work together to achieve precise testing.

- Loading System: Core Force Application Unit

Power Source: Servo motors (for high-precision control) or cylinders (for large load and rapid response) are used as power sources to drive the loading mechanism to output force values. Servo motors are suitable for scenarios requiring precise control of force and speed (such as micro-load fatigue tests), while cylinders are ideal for large-load, short-cycle rapid tests (such as impact load simulation).

Transmission Mechanism: Power is transmitted to the loading end through ball screws, synchronous belts, or gear sets to ensure stable and linear force transmission; some models use double guide rails to reduce lateral deviation and improve loading accuracy.

Load Application Components: The end is connected to a force sensor and a loading head (such as a flat plate, roller, or simulated finger), which directly acts on the surface of the handrail; the material of the loading head should match the actual usage scenario (for example, a soft silicone head is used for leather handrails to avoid scratches). - Fixture System: Sample Fixation Unit

Adjustable Fixtures: Composed of a base, clamping arms, and adjusting bolts, etc., the clamping arm spacing and angle can be adjusted to fit handrails of different sizes and shapes; some fixtures are equipped with pressure sensors to monitor the clamping force and prevent sample deformation due to excessive tightness.

Quick Clamping Mechanism: Such as pneumatic clamps or magnetic fixation devices, which can be opened and closed through buttons or pneumatic control, reducing sample change time (especially suitable for batch testing scenarios). - Control System: Test Logic Unit

Hardware: With PLC (Programmable Logic Controller) or industrial computer as the core, it receives sensor signals (force, displacement), controls the operation of motors/cylinders, and drives the Human-Machine Interface (HMI) to display data.

Software: The accompanying test software supports parameter setting (such as cycle times, load magnitude, frequency), real-time curve monitoring, data storage and export; some software supports custom test programs (such as simulating "pressing - friction - twisting" combined actions) to meet complex working conditions. - Support Frame: Equipment Support Unit

The main support is made of high-strength steel structure (such as welded square tube frames) to ensure the overall stability of the equipment; the surface of the frame is usually covered with anti-corrosion coatings (such as powder coating or galvanizing) to adapt to laboratory or workshop environments.

Linear guide rails are set on the top or side of the frame for installing the loading mechanism, ensuring the linear movement accuracy of the loading head. - Auxiliary Devices: Test Optimization Unit

Safety Devices: Such as transparent acrylic safety shields or mechanical guardrails to prevent sample fragments from flying or operators from accidentally touching moving parts; some models are equipped with sound and light alarms to alert operators in case of abnormal conditions.

Environmental Simulation Components (Optional): For special test requirements (such as durability under high temperature and high humidity), temperature and humidity control boxes can be integrated to simulate actual usage environments.

Displacement Measurement Devices: Such as grating rulers or laser displacement sensors, which monitor the deformation of the handrail under load in real time for analyzing structural stability.

Test standards:

1、ISO 28809: Road Vehicles - Interior Components - Test Methods for Durability of Armrests and Support Structures

2、SAE J1727: "Test Procedure for Durability of Automotive Seat Assembly"

3、GB/T 29607-2013: "Requirements and Test Methods for Strength of Automotive Seats and Seat Head Restraints"

4、EN 1335-3: Office furniture - Seating - Part 3: Safety requirements and test methods

5、BIFMA X5.1: Performance Standard for Office Seating (Business and Institutional Furniture Manufacturers Association)

6、EN 581-2: Outdoor furniture - Chairs and tables - Part 2: Safety requirements and test methods for leisure chairs

7、GB/T 3326-2016: "Furniture - Main Dimensions of Tables and Chairs"

Installation Environment Requirements Spatial layout

Sufficient operating space should be reserved around the equipment (it is recommended that there be at least 1 meter on each side), to facilitate sample loading and unloading, fixture adjustment and daily maintenance. If a protective cover or safety door is equipped, it is necessary to ensure that the opening and closing space is not restricted.

A gap of at least 10 cm should be left between the bottom of the equipment and the ground to facilitate the arrangement of cables and air lines (if any) and heat dissipation.

Ground conditions

The ground should be flat and solid (with a level error of no more than 2 mm/m²) to avoid vibration or displacement of the equipment during operation due to ground inclination. If the ground is uneven, shims or a level should be used to calibrate the base. If the equipment is heavy (such as over 500 kg), it is recommended to install it on a load-bearing wall or a hardened ground surface. If necessary, use expansion bolts to fix the base to prevent displacement during testing due to vibration.

Environmental temperature and humidity

The recommended operating environment temperature for the equipment is 10°C to 35°C (for some high-precision models, it is 20°C ± 5°C), and the relative humidity is 40% to 70% RH. Avoid high-temperature, high-humidity or strongly corrosive environments (such as acid/alkali vapor) that may affect the lifespan of electrical and mechanical components.

If the test standard requires extreme environments (such as the -40°C to 85°C durability test for car armrests), the installation location and connection pipelines of the environmental test chamber should be planned in advance.

Ventilation and dust prevention

The equipment may generate heat during operation (especially from components such as servo motors and cylinders), so it is necessary to ensure good ventilation around it to avoid heat accumulation. If it is installed in a closed space, it is recommended to install exhaust fans or air conditioners. Dust, metal shavings and other contaminants should be prevented from entering the equipment (such as transmission mechanisms and sensors). If necessary, install a dust cover above the equipment or set up an independent operation room.