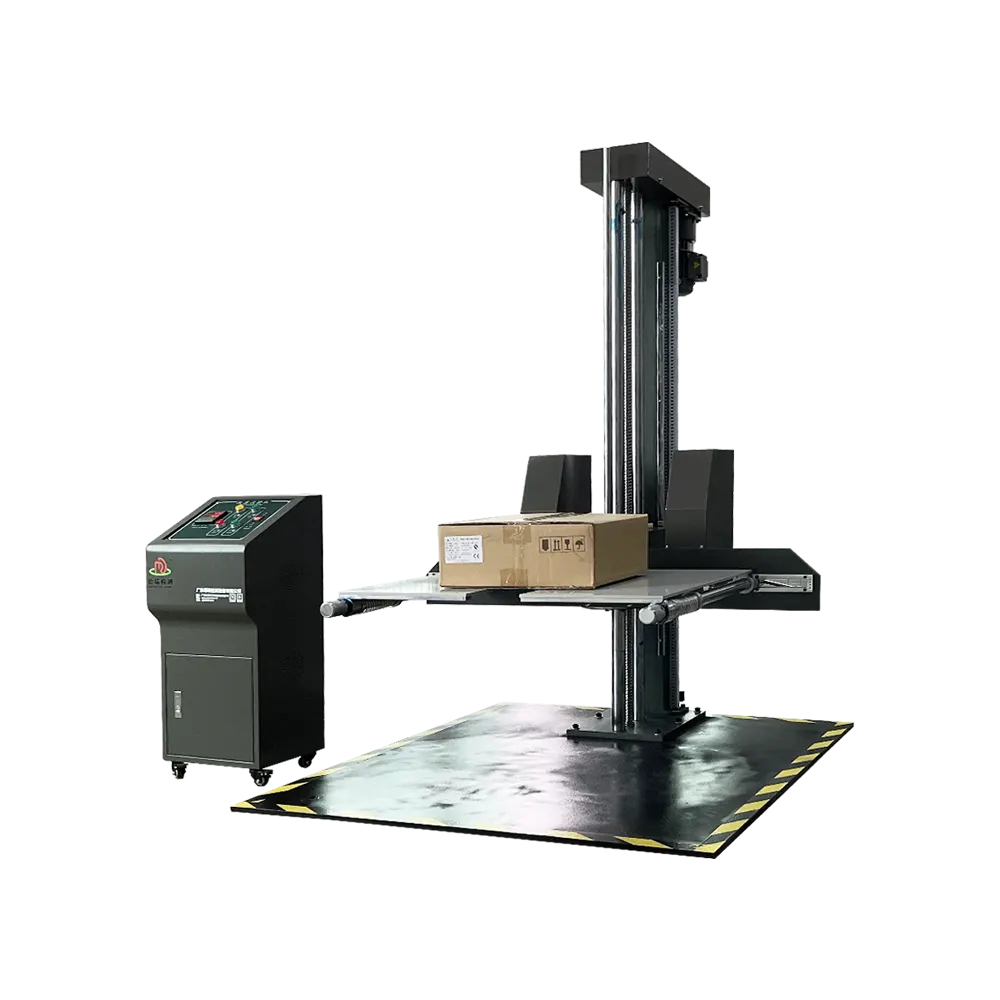

The single-wing drop tester is developed to replicate the scenario where packaged products fall from various heights, landing on the ground with different edges, corners, or surfaces. This enables a thorough evaluation of product damage and allows for an assessment of the packaging components' ability to withstand impact during drops, ultimately contributing to packaging enhancement.

Our packaging single wing drop test equipment features multiple unique advantages, ensuring the safety of products during transportation and storage. Firstly, the equipment is made of high-strength materials, capable of withstanding significant impact forces to guarantee the integrity of the packaging. Secondly, the design is simple and user-friendly, reducing operation time and enhancing overall work efficiency. We also offer customization services to meet the specific needs of customers in various industries.

The key features of the Single Wing Drop Test equipment are as follows:

1、The main column is made of specially selected high-quality steel, precisely ground on the outer diameter and chrome-plated on the surface, demonstrating outstanding strength, durability and rust resistance.

2、It uses ST special custom chains to ensure the stability and reliability of the equipment operation.

3、It supports comprehensive drop tests on the surface, edges and corners of products, meeting diverse testing requirements.

4、It is equipped with electric reset, electric drop control and electric lifting functions, making operation simple and efficient.

5、It can achieve smooth separation of the goods tray and the packaging sample, ensuring the packaging sample falls freely with low impact vibration and stable operation.

6、It is equipped with a digital height indicator and a decoder to track the height in real time, precisely controlling and displaying the drop height of the product, enhancing testing accuracy.

Packaging Single Wing Drop Test equipment Precautions and Maintenance

1、The testing machine's casing must be reliably grounded to avoid the risk of electric shock.

2、At the power supply input, install an air switch or contactor with the same or higher capacity, featuring leakage protection, to promptly disconnect power in emergencies.

3、While the machine is in operation, avoid touching any components except for the control panel to prevent injuries such as scratches or pinches.

4、If moving the machine, ensure the power is disconnected and allow a cooling period of at least 5 minutes before proceeding.

5、Upon installation of a new machine in the factory, apply an appropriate amount of low-concentration machine oil to the sliding round rods. Avoid using anti-rust oil, high-concentration machine oil, or any other oils that may cause corrosion.

6、After prolonged use, if excessive dust accumulates on the oiled areas, lower the machine to its base, clean off the existing machine oil, and reapply it. Regular maintenance includes adding lubricating oil to the machine's transmission components.

7、The Single Wing Drop Test equipment impact device. After using the new machine more than 500 times, check and tighten all screws to prevent potential malfunctions.