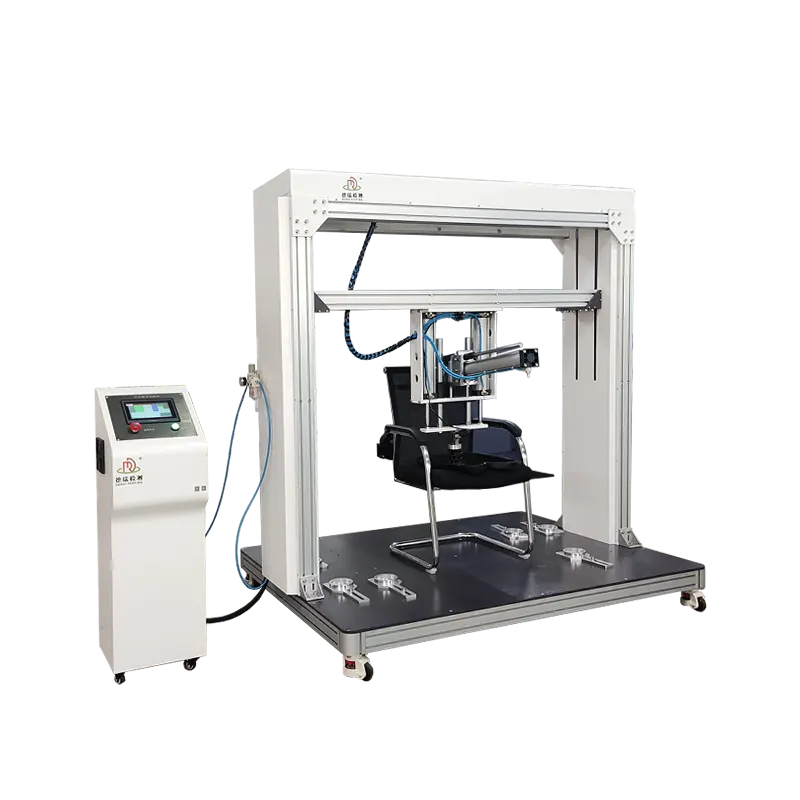

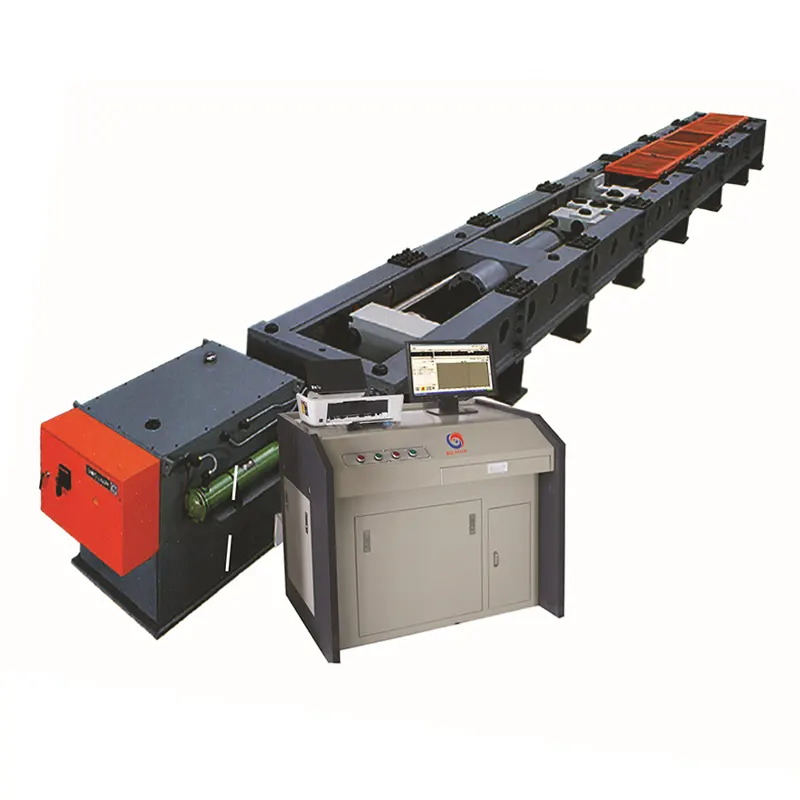

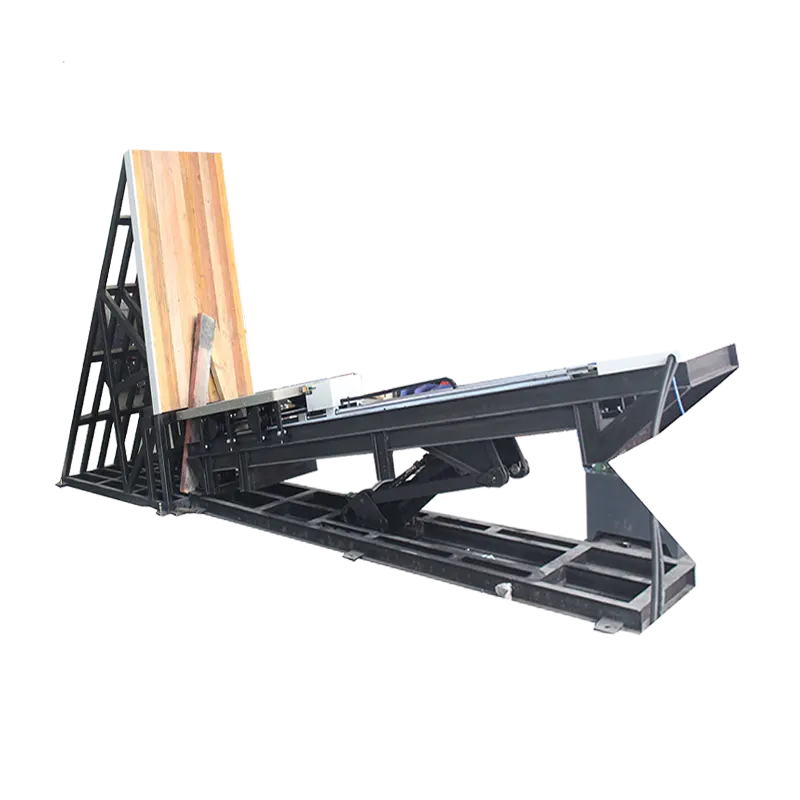

The fully automatic mattress testing equipment (rolling + edge pressing + softness and hardness + height measurement) is a mattress testing device designed to simulate the constant rolling during human sleep. The rolling durability test uses a rolling loading module placed on the loading area of the horizontally placed mattress, which rolls at a certain frequency to apply reciprocating loads to the mattress, to test the mattress's ability to withstand long-term repetitive rolling loads. The edge pressing test is to apply pressure to the edge of the mattress to test its durability. The surface softness and hardness test measures the softness and hardness of the mattress to meet the requirements of various mattress manufacturers and standards. It is used to determine the quality and service life of the mattress and strictly complies with the requirements of national standards for mechanical testing. It is suitable for strong spring mattresses, ordinary spring mattresses, foam mattresses, and brown fiber elastic mattresses, etc.

Meet the standards

Complies with the requirements for mechanical testing as stipulated in GB/T 26706-2011 "Soft Furniture - Mattresses with Coir Fiber Elasticity", QB/T 1952.2-2011 "Soft Furniture - Spring Mattresses", and BS EN 1957:2012 standards.

Working principle

This machine is a mattress durability testing machine. The testing method is as follows: Secure the mattress to be tested, turn on the testing equipment, select the type of mattress to be tested, automatic/manual and other parameters through the computer, and the equipment will automatically run according to the set parameters. The test results will be printed by the printer.

Product Features

- This equipment meets four testing methods: pavement rolling endurance test, softness and hardness test, and cushion height test.

- It is computer-controlled and can achieve fully automatic test results. It features one-button control for both fully automatic operation and manual operation modes.

- Materials used meet the following requirements: the mechanical main body adopts a standard industrial high-strength aluminum profile frame structure, Taiwan TBI self-lubricating linear guide rails, Japanese servo motors, and well-known brand force value sensors, etc.

- The cushion height test is driven by a servo motor, and the test is conducted at the speed specified by the standard. It displays the curve graph of the force value applied by the loading pad on the test piece and the corresponding indentation value, and automatically measures the height.

- The roller is made of nylon material that meets the requirements of dynamic/static friction coefficient (0.2-0.5), with hollow stepped embedded processing. It is equipped with a counterweight that does not rotate with the roller, which meets the requirements of moment of inertia (0.5±0.05) kgm2 and the requirement of vertical applied force (1400±7) N.

- The pavement rolling endurance test part adopts a gantry mechanical structure, with a high-thrust servo motor and high-precision heavy-duty linear guide rails as transmission components. A well-known brand computer is used as the input control to make the operation control more user-friendly and straightforward.

- The loading of the rolling test in the pavement endurance test uses a linear sliding bearing for free loading. The endurance test uses a loading block and a linear sliding bearing for free loading. Since there is only linear bearing rolling friction, the accuracy of the loading force can be guaranteed. Therefore, the loading force is more in line with the standard requirements.

- The midpoint positioning in the rolling test is automatic, finding the midpoint of the mattress without the need for manual repositioning. The PLC is used for starting point positioning.