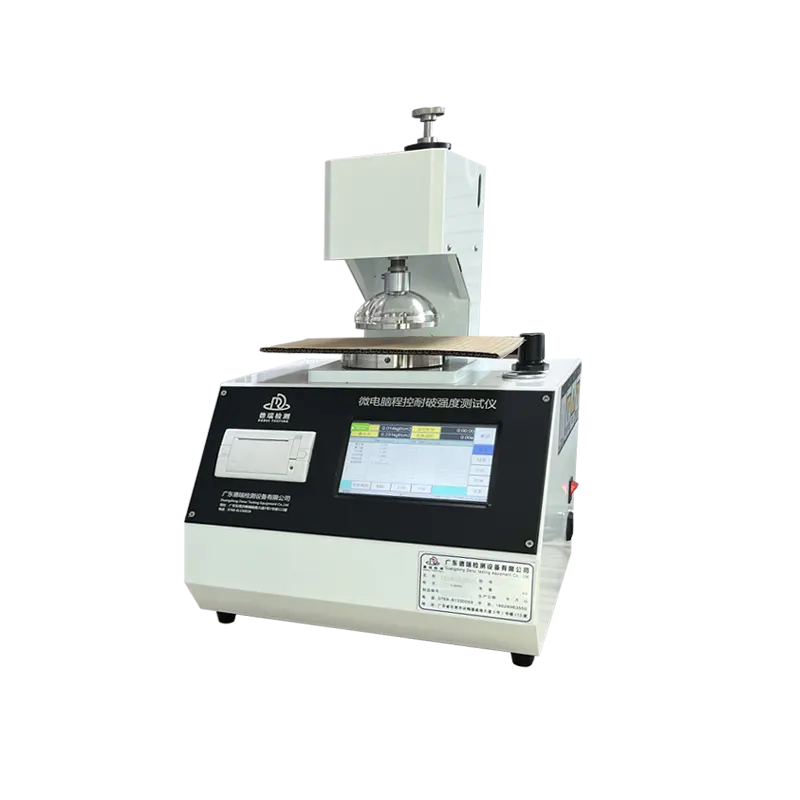

What is an Automatic Bursting Strength Tester

An automatic bursting strength tester is a device designed to measure the bursting strength of various materials quickly and accurately. It works by applying controlled pressure to a sample until it bursts, recording the maximum force the material can withstand. This basic principle helps assess the durability and quality of fabrics, paper, cardboard, and packaging materials.

Unlike manual bursting strength testers, which require operators to control pressure application and measure results by hand, the automatic version uses advanced technology to automate the entire process. This ensures consistent pressure application, precise readings, and faster test cycles.

Key components include:

- Load cell: Measures the force applied during the test with high accuracy.

- Pneumatic or hydraulic system: Applies uniform pressure to the sample until failure.

- Digital display and control panel: Shows test results instantly and allows easy operation.

- Software integration: Enables data logging, analysis, and report generation.

Typical materials tested with these machines include textiles, non-woven fabrics, paper, cardboard, and various packaging materials like cartons and plastic films. This versatility makes the automatic bursting strength tester a valuable tool across industries where material strength and quality control are critical.

Why Use an Automatic Bursting Strength Tester

Using an automatic bursting strength tester brings clear advantages over manual methods, especially for businesses focused on quality and efficiency. Here’s why investing in one makes sense:

- Automation Boosts Precision and Speed: Automatic testers deliver consistent and highly accurate results, cutting down testing time significantly. This means more samples tested in less time without compromising on precision.

- Repeatability for Reliable Quality Control: By removing human variability, these machines ensure every test is done the same way, making your quality control process dependable.

- Enhanced Safety and Easy Operation: Modern automatic testers come with built-in safety features that protect operators during pressure tests. The user-friendly interfaces require minimal training, making them accessible for different skill levels.

- Minimizes Human Error: Automated controls reduce mistakes that can happen from manual handling or reading errors, ensuring reliable data for better decision-making.

- Compliance with International Standards: These testers meet key global benchmarks like ISO, ASTM, and TAPPI, which is crucial for businesses in the U.S. aiming for worldwide market acceptance and regulatory compliance.

In short, an automatic bursting strength tester helps you keep your testing efficient, safe, accurate, and up to industry standards—key factors for staying competitive and ensuring product quality.

How Does an Automatic Bursting Strength Tester Work

Using an automatic bursting strength tester is straightforward and efficient. Here’s how the process typically works:

- Sample PlacementYou start by placing a prepared sample, like fabric, paper, or packaging material, on the tester’s clamping area. The sample is held firmly to prevent any movement during testing.

- Initiating the TestOnce the sample is secure, the machine automatically begins applying pressure. Most modern testers use a hydraulic or pneumatic system to gradually increase pressure until the material bursts.

- Bursting MechanismThis pressure is applied evenly through a diaphragm or piston. The hydraulic or pneumatic setup controls the force accurately, measuring the exact pressure needed to cause the material to fail.

- Data CaptureWhen the sample bursts, sensors detect the maximum force applied. This data is instantly sent to the digital display and stored in the machine’s memory.

- Result Display and AnalysisThe pressure value, often shown in units like kPa or psi, appears on the screen. Many testers include software options for logging results, analyzing trends, and exporting data for quality control records.

In short, the automatic bursting strength tester simplifies what was once a manual task, delivering fast, reliable results with minimal human intervention. This efficiency is essential for maintaining consistent product quality in busy labs and manufacturing setups.

Key Features to Look for in a Quality Automatic Bursting Strength Tester

When choosing an automatic bursting strength tester, focus on these essential features to ensure reliable, efficient testing:

Measurement Accuracy and Range

- High precision load cells for consistent results

- Wide testing range to cover thin fabrics to thick cardboard

- Repeatable readings for quality control

Automation Level and User Interface

- Fully automated testing cycles to save time

- Easy-to-use touchscreen with clear menus

- Programmable test sequences for different materials

Sample Size Capacity and Supported Types

- Compatibility with various sample sizes and shapes

- Supports textiles, paper, cardboard, and packaging materials

- Adaptable clamps or holders for non-woven and specialty materials

Durability and Maintenance Needs

- Sturdy construction with corrosion-resistant parts

- Low maintenance design for long-term use

- Easy access for calibration and cleaning

Compliance with Industry Standards

- Meets ISO 2758, ASTM D3786, TAPPI, and other relevant standards

- Ensures your testing results are accepted globally

Calibration and Certification Options

- Built-in calibration routines or external calibration support

- Certification services for compliance verification

- Software logging to track calibration history

| Feature | What to Look For |

|---|---|

| Accuracy | High-precision sensors, reliable repeatability |

| Automation | Touchscreen UI, programmable tests |

| Sample Support | Multiple sizes, fabric, paper, packaging |

| Durability | Solid build, corrosion resistance |

| Industry Compliance | ISO, ASTM, TAPPI certified |

| Calibration | Easy calibration, certification options |

These features help ensure your automatic bursting strength tester meets your business needs with precision and ease.

Applications of Automatic Bursting Strength Testers by Industry

Automatic bursting strength testers play a crucial role across various industries in the U.S., where consistent material quality is a must. Here’s how different sectors make the most of this equipment:

- Textile and Fabric Strength TestingThese testers measure the bursting strength of fabrics like cotton, polyester, and blends. This helps ensure clothing, upholstery, and industrial textiles can handle real-world stresses without tearing or failing.

- Paper and Cardboard Quality ControlPaper mills and packaging producers rely on bursting strength testers to check the durability of paper sheets, cardboard, and corrugated materials. It ensures products meet standards like ISO 2758 or ASTM D3786, guaranteeing strength and reliability.

- Packaging Material TestingFor packaging manufacturers, testing bursting strength is key to confirming that cartons, boxes, and flexible packaging resist pressure and protect contents during shipping and handling.

- Non-Woven Materials and Specialty ApplicationsIndustries working with non-woven fabrics—such as medical supplies, filters, or automotive components—use these testers to verify that their materials meet required strength criteria, making sure products perform safely and effectively.

By covering this range of materials and industries, automatic bursting strength testers help U.S. businesses maintain quality, reduce waste, and improve product safety.

How to Choose the Right Automatic Bursting Strength Tester for Your Business

Picking the right automatic bursting strength tester means matching the machine to your specific needs. Here’s what you should consider:

Assess Sample Types and Production Volume

- Material Types: Know what you’re testing—textiles, paper, cardboard, or packaging materials. Make sure the tester supports those.

- Sample Size and Thickness: The tester must handle your material sizes and thickness ranges reliably.

- Production Scale: High production volume calls for faster machines with more automation.

Consider Test Speed and Automation Needs

- Faster testing means better throughput, especially in busy labs or production lines.

- Look for machines with features like programmable tests and quick sample setup to save time.

Integration with Existing Lab or Production Systems

- Check if the tester supports software integration for data logging and analysis.

- Compatibility with your current lab management or production control systems can boost efficiency.

Budget Considerations and Return on Investment (ROI)

- Balance upfront cost with long-term savings from automation, accuracy, and reduced errors.

- Consider maintenance costs and downtime—investing in reliable equipment pays off.

Importance of After-Sales Service and Technical Support

- Choose brands with strong customer support in the U.S., including quick access to parts and service.

- Training availability and user manuals tailored to your needs can reduce operator errors.

| Factor | Why It Matters | What to Look For |

|---|---|---|

| Sample Types & Volume | Ensure compatibility and capacity | Material range, sample size limits |

| Test Speed & Automation | Maximize output and efficiency | Programmable tests, fast cycles |

| System Integration | Streamline data handling | Software compatibility |

| Budget & ROI | Get best value and minimize downtime | Cost vs features balance |

| Support & Service | Keep equipment running and operators trained | Local support, training options |

Choosing the right automatic bursting strength tester means thinking beyond just specs. Focus on your daily needs, growth plans, and support to make a smart, future-proof investment.

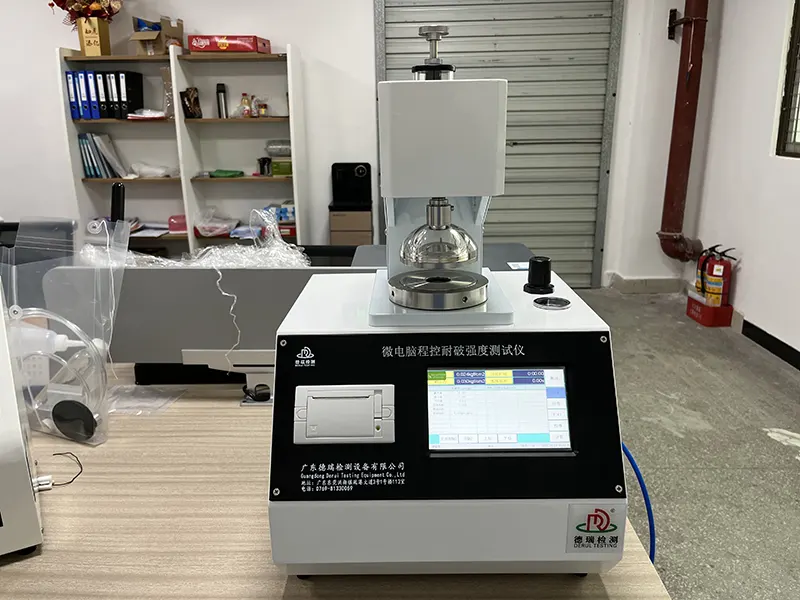

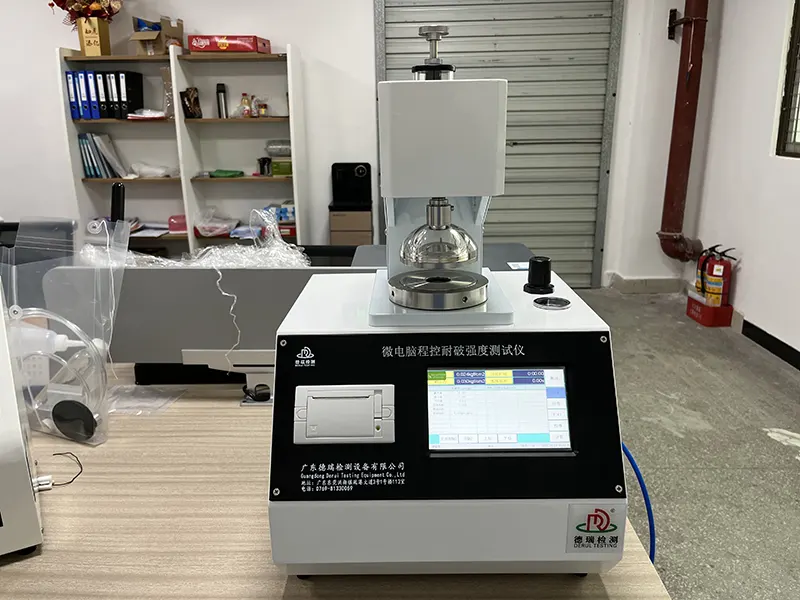

Derui’s Automatic Bursting Strength Tester Features and Benefits

Derui is a trusted name in the US market for automatic bursting strength testers. Known for quality and reliability, Derui delivers advanced equipment suited for textile, paper, packaging, and non-woven material testing.

Product Range Overview

Derui offers a range of bursting strength testing machines designed for different needs:

| Model | Material Support | Automation Level | Key Feature |

|---|---|---|---|

| Derui DBS-100 | Fabric, Paper | Fully automatic | High precision load cell |

| Derui DBS-200 | Packaging materials | Semi-automatic | Pneumatic bursting system |

| Derui DBS-300 | Non-woven, specialty apps | Fully automatic | Digital touchscreen interface |

Unique Derui Advantages

- Precision and Accuracy: Uses advanced load cells and hydraulic/pneumatic systems for consistent results.

- User-Friendly Interface: Touchscreen displays with programmable settings simplify tests.

- Fast Testing Speed: Cuts down test time without sacrificing accuracy, boosting lab productivity.

- Robust Build: Designed to handle regular use in busy labs and production environments.

- Software Integration: Easy data logging and report generation for quality control and compliance needs.

Customer Feedback

US customers appreciate Derui testers for:

- Reliable and repeatable results that meet ISO 2758 and ASTM D3786 standards.

- Excellent after-sales support and responsive technical service.

- Easy installation and minimal training required.

- Enhanced safety built into automatic operations, reducing risk during testing.

Derui’s automatic bursting strength testers offer a solid combination of technology, usability, and support tailored to fit the US manufacturing and quality assurance landscape.

Maintenance Tips for Prolonging the Life of Your Automatic Bursting Strength Tester

Keeping your automatic bursting strength tester in top shape helps ensure accurate results and extends its lifespan. Here are some straightforward maintenance tips:

Routine Calibration and Checks

- Schedule regular calibration according to the manufacturer’s guidelines to maintain accurate readings.

- Perform routine system checks on load cells, pneumatic systems, and digital displays.

- Keep a log of calibration dates and any adjustments made.

Cleaning and Handling Best Practices

- Clean the machine’s surfaces and testing area after each use to prevent dust and debris buildup.

- Use a soft, dry cloth or recommended cleaning agents—avoid harsh chemicals.

- Handle samples carefully; rough handling can damage sensitive components like the hydraulic diaphragm or load cells.

Troubleshooting Common Issues

- If the results seem off, re-check calibration and ensure the sample is correctly placed.

- Watch for unusual noises during testing—it could signal a pneumatic or hydraulic issue.

- Reset the device or reinstall software if data capture or display lags.

- Refer to the user manual for quick fixes before calling support.

When to Seek Professional Service

- If calibration fails repeatedly or you notice persistent mechanical or electronic malfunction.

- When any major part, like the pressure system or digital control unit, shows wear or damage.

- Regular professional servicing is recommended annually or per usage intensity to keep the tester reliable.

By following these simple maintenance steps, you’ll keep your bursting strength testing equipment working accurately and efficiently for years—saving time and avoiding costly repairs.

Frequently Asked Questions about Automatic Bursting Strength Testers

How accurate are automatic bursting strength testers?

Automatic bursting strength testers are highly accurate, often delivering repeatable results within a tight margin of error. They use precise load cells and digital sensors, which makes them more reliable than manual testers.

Can these testers handle different material thicknesses?

Yes, most automatic bursting strength testers are designed to test a wide range of material thicknesses. Whether it’s thin fabric, thick cardboard, or non-woven materials, the machine adjusts pressure accordingly for consistent results.

How long does a typical test take?

A single bursting strength test usually takes just a few seconds to complete. Automation speeds up the process by quickly applying pressure and capturing data, making it ideal for high-volume quality control.

Are there international standards for bursting strength testing?

Absolutely. Common standards like ISO 2758, ASTM D3786, and TAPPI protocols guide bursting strength testing. Using an automatic bursting strength tester helps ensure your tests comply with these recognized industry benchmarks.

What training is required to operate the machine?

Operating an automatic bursting strength tester is straightforward. Most users need basic training on sample preparation, machine setup, and software use. Many manufacturers provide quick start guides and support to get you running smoothly with minimal downtime.