If you’re serious about knowing exactly how strong your materials are, understanding their ultimate tensile strength is non-negotiable. That’s where an ultimate tensile strength testing machine comes in—an essential tool that puts the durability and performance of metals, plastics, composites, and more under the microscope. Whether you’re in manufacturing, aerospace, or quality control, having precise, reliable data on tensile strength can make or break your product’s success. In this guide, we’ll dive into what these machines do, why they matter, and how Derui’s cutting-edge testing solutions stand out—helping you get the accuracy and support you need to keep your materials and projects running strong.

Understanding Ultimate Tensile Strength

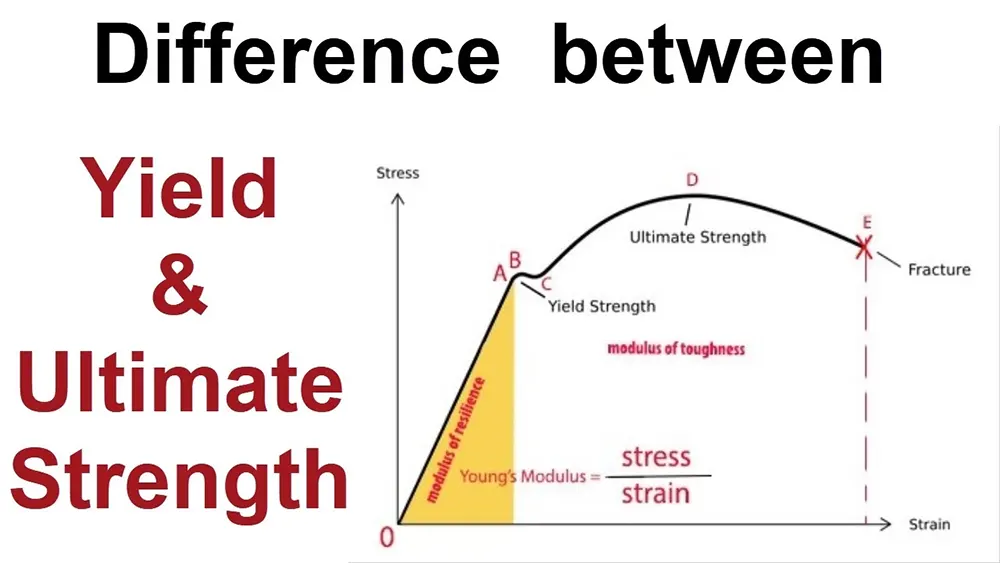

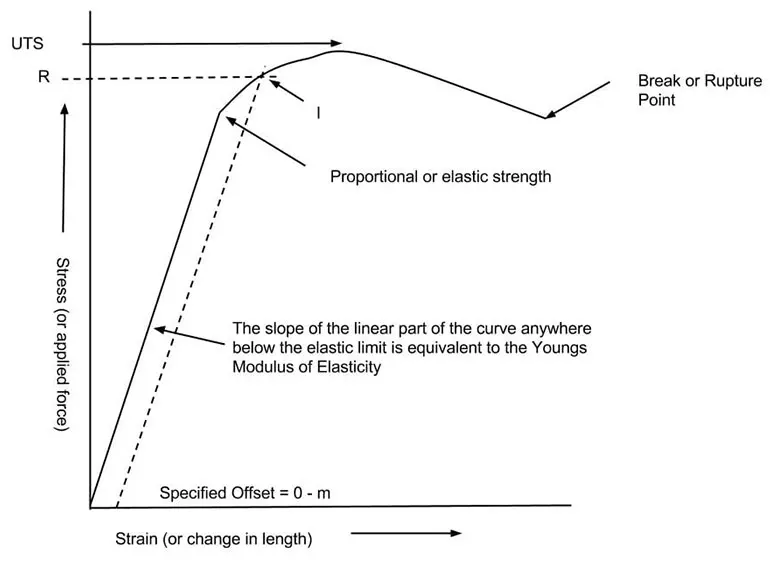

Ultimate Tensile Strength (UTS) is the maximum stress a material can withstand while being stretched or pulled before breaking. It’s one of the most important mechanical properties used to gauge a material’s strength and durability. UTS is measured in units like pounds per square inch (psi) or megapascals (MPa).

Unlike yield strength, which marks the point where a material begins to deform permanently, UTS represents the highest point on the stress-strain curve before failure. Other properties like elongation or modulus of elasticity describe different aspects such as ductility or stiffness, while UTS focuses specifically on maximum load capacity.

Accurate measurement of UTS is critical because it helps ensure materials meet safety and quality standards. It guides engineers and manufacturers in selecting the right materials for products and applications, preventing failures that could lead to costly damages or safety hazards. Whether you’re testing metals, plastics, or composites, understanding true tensile strength is fundamental to material performance evaluation.

Components and Working Principle of an Ultimate Tensile Strength Testing Machine

An ultimate tensile strength testing machine is built with several key parts working together to measure how much force a material can handle before breaking. Here’s what you’ll find in most machines:

- Load Frame: The main structure that holds the entire setup and supports the material sample during testing.

- Grips: These clamp onto the sample securely, preventing slipping while the machine pulls on it.

- Extensometers: Devices that measure how much the material stretches or elongates while being pulled.

- Control Unit: The brain of the machine, controlling how the test runs and collects data.

- Software: Displays results in real-time and calculates the ultimate tensile strength, along with other key properties.

How the Testing Process Works

- Sample Preparation: A test piece of the material is carefully shaped according to standards.

- Mounting the Sample: The grips clamp the sample firmly inside the load frame.

- Starting the Test: The machine pulls the sample at a controlled speed.

- Measuring Force and Elongation: Load cells track the force applied, while extensometers measure how much the material stretches.

- Calculating UTS: The software uses the highest force recorded before the sample breaks and divides it by the original cross-sectional area to find the ultimate tensile strength.

By monitoring force and elongation together, the machine provides a stress-strain curve that reveals not just UTS but other mechanical properties like yield strength and elongation at break. This step-by-step setup ensures accurate, reliable tensile strength measurement for a wide range of materials.

Types of Ultimate Tensile Strength Testing Machines

When choosing an ultimate tensile strength testing machine, it’s important to understand the main types and their features. Here’s a quick breakdown:

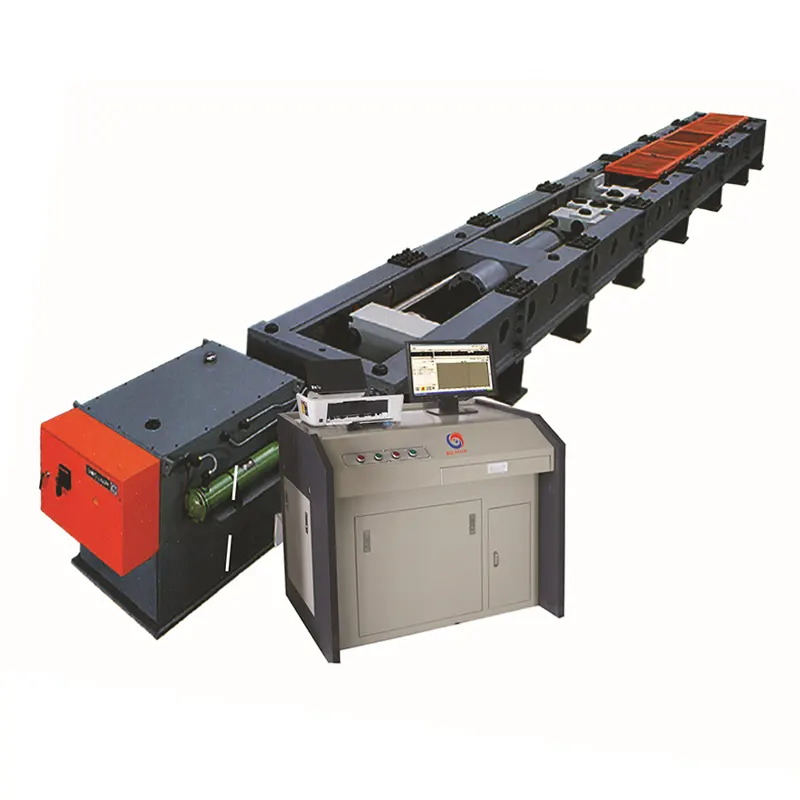

Hydraulic vs Electromechanical Machines

| Feature | Hydraulic Machines | Electromechanical Machines |

|---|---|---|

| Power | Uses fluid pressure | Uses electric motors |

| Load Capacity | Generally higher, good for heavy-duty | Moderate to high, precise control |

| Speed | Slower, steady | Faster, adjustable speed |

| Maintenance | More complex, needs fluid checks | Easier maintenance |

| Typical Use | Heavy metals, large samples | Plastics, composites, metals |

Universal Testing Machines (UTM)

Universal testing machines can handle tension, compression, and bending tests. Most UTMs support tensile testing, making them versatile for labs and production floors.

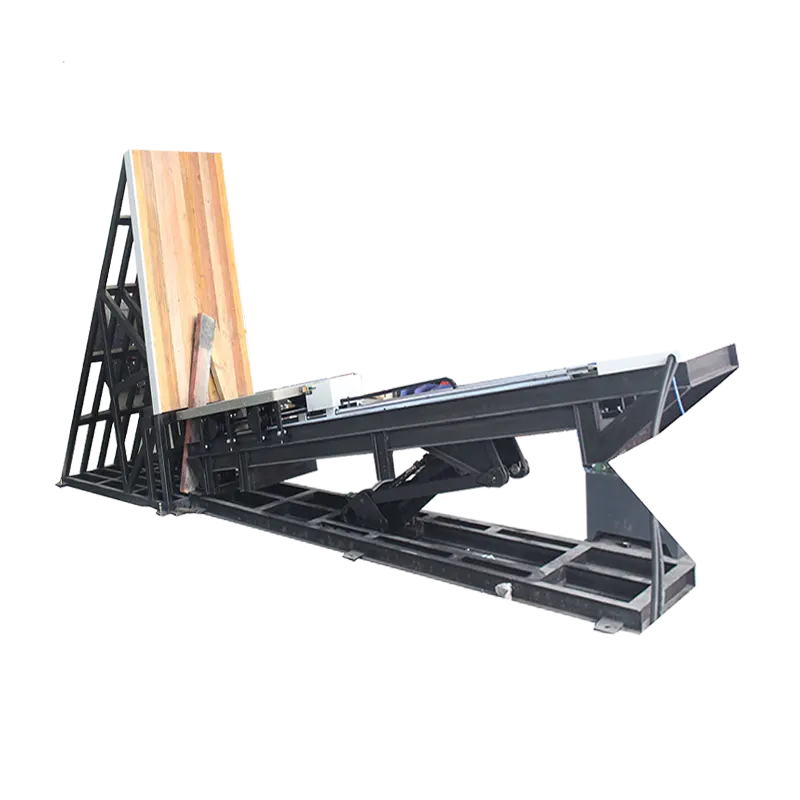

Bench Top vs Floor Standing Models

| Type | Description | Best For |

|---|---|---|

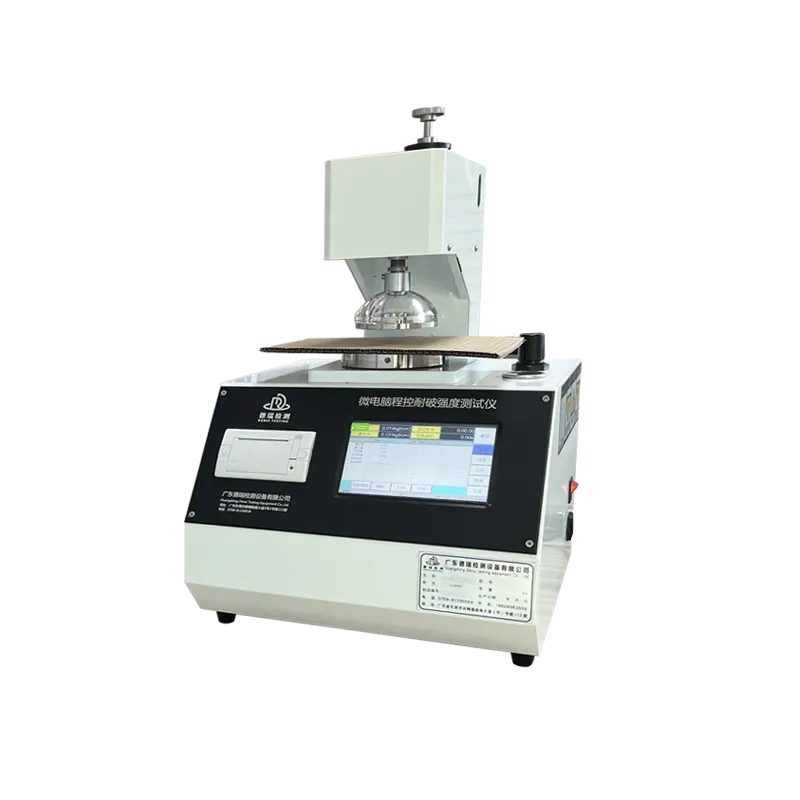

| Bench Top | Compact, smaller footprint | Small labs, low-volume testing |

| Floor Standing | Larger, higher capacity | Industrial use, big samples |

Key Features to Consider

- Load Capacity: Choose based on the maximum force your samples require.

- Accuracy: Look for machines with precise load cells and extensometers.

- Data Output: Ability to connect to computers or software for easy data collection and analysis.

- Speed Control: Adjustable testing speed helps for different materials.

- Standards Compliance: Machines that meet ASTM and ISO standards ensure reliable results.

Understanding these options helps you pick the right machine tailored to your testing needs and budget.

Applications of Ultimate Tensile Strength Testing Machines

Ultimate tensile strength testing machines are essential in many areas, especially for ensuring materials meet quality and safety standards. Here’s where you’ll find these machines making a real difference:

Quality Control and Assurance

Manufacturers rely on tensile strength testing to check if their products hold up under stress. This helps catch weak batches before they reach customers, maintaining consistent quality.

Research and Development

New materials and composites get tested to understand their strength and flexibility. This data drives innovation by helping engineers develop tougher, lighter, or more durable materials.

Compliance with Standards

UTS testing ensures materials and products meet local and international standards like ASTM and ISO. Meeting these standards is crucial for legal compliance and market approval in the U.S.

Industries and Materials Tested

- Metals such as steel and aluminum

- Plastics and polymers

- Composite materials used in aerospace and automotive sectors

- Textiles and fibers in manufacturing

These machines help engineers, manufacturers, and quality teams in industries from construction and automotive to packaging and electronics confirm the strength and reliability of their materials.

Why Choose Derui’s Ultimate Tensile Strength Testing Machines

When it comes to ultimate tensile strength testing machines, Derui offers a solid lineup designed to meet a variety of testing needs across industries. Whether you’re working with metals, plastics, or composites, Derui has models that fit different sample sizes and load capacities.

Derui Product Range Highlights

- Electromechanical and hydraulic machines for flexible testing setups

- Bench top and floor-standing models to suit your workspace

- Testing machines built for low to high load capacities—ideal for both small labs and large manufacturers

Unique Features and Innovations

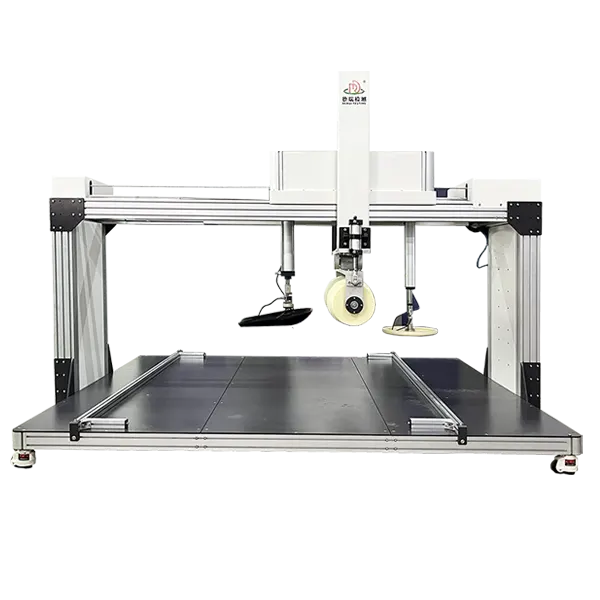

Derui stands out by incorporating smart automation and easy controls:

- Precision automation ensures repeatable, reliable measurements every time

- User-friendly interfaces simplify setup and test execution, perfect for operators of all experience levels

- Advanced data management helps with tracking, reporting, and exporting results effortlessly

Local Support and After Sales Service

Customers in the U.S. benefit from:

- Fast response times with regional service centers

- On-site installation and training to get you up and running quickly

- Ongoing maintenance packages that keep your machine in top shape

What Customers Are Saying

- Businesses praise Derui for accurate test results and durable equipment

- Many highlight the responsive customer service as a reason to stick with Derui

- Case studies show improved quality control and faster R&D cycles thanks to Derui tensile strength testing machines

Choosing Derui means getting dependable equipment backed by solid support, helping your operations stay efficient and compliant with ASTM tensile testing standards.

How to Select the Right Ultimate Tensile Strength Testing Machine for Your Needs

Choosing the right ultimate tensile strength testing machine comes down to a few key factors that match your specific testing requirements. Here’s what to consider:

- Material TypeDifferent materials like metals, plastics, or composites may need specialized grips or sensors. Make sure the machine supports your material of interest for accurate tensile strength measurement.

- Test Range and Load CapacityKnow the maximum force your samples will require during testing. Selecting a machine with the proper load capacity ensures safety, accuracy, and prevents equipment damage.

- Sample Size and ShapeThe testing machine should accommodate the size and shape of your specimens. Whether you work with small test coupons or larger samples, pay attention to grip options and test space.

- BudgetBalance cost with needed features. Sometimes bench top models fit small labs or light testing budgets, while floor standing machines offer more capacity and versatility but cost more.

- Accuracy and Standards ComplianceLook for machines that comply with ASTM tensile testing standards like ASTM E8 / A370 to ensure your results are reliable and accepted in industry.

- Data Output and SoftwareEasy-to-use software and clear data reporting help you analyze test results quickly and meet quality assurance requirements.

Derui’s Expert Consultation and Customization

At Derui, we understand that every lab or manufacturing setup is different. Our experts work directly with you to pick or customize a tensile strength testing machine that fits your materials, volume, and workflow. This includes:

- Tailored configurations based on your test range and sample types

- Software options to meet your data reporting and quality control needs

- Recommendations for machines balancing precision and budget

Working with Derui means you get a testing machine designed to deliver precise, repeatable results with the support you need for ongoing success.

Setting Up and Maintaining Your Ultimate Tensile Strength Testing Machine

Proper setup and maintenance of your ultimate tensile strength testing machine are key to getting accurate results and extending the life of your equipment. Here’s a straightforward guide to help you get started and keep your machine running smoothly.

Installation Tips and Initial Setup

- Choose the Right Location: Place your machine on a stable, vibration-free floor with enough space around it for easy operation and maintenance.

- Level the Machine: Use a spirit level to ensure the machine is perfectly level. This helps in accurate force and elongation measurements.

- Electrical Requirements: Verify that your power supply matches the machine’s requirements. Grounding the machine properly avoids electrical issues.

- Connect Accessories: Attach grips, extensometers, and other parts securely. Make sure software and control units are installed and updated.

- Calibration: Always perform calibration before first use to confirm load cells and extensometers give correct readings per ASTM tensile testing standards.

Routine Maintenance Practices

- Keep It Clean: Wipe down the machine after each test to remove dust and debris that could affect moving parts.

- Lubricate Moving Parts: Regularly oil the guide rods and screws to prevent wear and keep the machine operating smoothly.

- Check Load Cells and Grips: Inspect for wear or damage before every test. Replace any parts that show signs of fatigue.

- Software Updates: Keep your testing software current to benefit from improved features and security fixes.

- Periodic Professional Service: Schedule yearly service with Derui’s support team to ensure everything stays in top condition.

Troubleshooting Common Issues

- Machine Won’t Power On

- Check power connection and fuse.

- Confirm emergency stop is disengaged.

- Inaccurate or Fluctuating Readings

- Recalibrate load cells and extensometers.

- Ensure grips are firmly holding the sample with no slipping.

- Software Crashes or Freezes

- Restart the computer and software.

- Check for updates or reinstall the control software.

- Unusual Noises or Resistance

- Inspect for debris or worn mechanical parts.

- Lubricate moving components or call for maintenance support.

By following these setup and care tips, your ultimate tensile strength testing machine will deliver reliable results and last longer—making it a smart investment for your testing needs.

Latest Trends and Technological Advancements in Tensile Strength Testing

The world of ultimate tensile strength testing machines is evolving fast, driven by digitalization and smart technology. Today’s machines don’t just pull and record data—they integrate with software and networks to deliver deeper insights and more convenience.

Digitalization and Smart Machine Integration

Modern tensile strength testing machines now come with built-in smart features that automate test procedures and improve accuracy. These smart systems reduce human error and speed up testing by automatically adjusting settings based on the material being tested. Integration with digital platforms means results can be stored and shared effortlessly, helping labs stay organized and compliant with ASTM tensile testing standards.

Enhanced Data Analytics and Reporting

Advanced tensile test machines offer detailed data analysis beyond just ultimate tensile strength. They provide stress-strain curves, yield strength, elongation, and other mechanical properties all in one place. These tools generate customizable reports quickly—great for quality assurance teams who need to track trends or pinpoint issues across batches.

Remote Monitoring and IoT Capabilities

One of the biggest tech advances is the ability to monitor tests remotely. Thanks to IoT connectivity, operators can watch machine performance and test progress in real-time from anywhere. This capability also supports predictive maintenance—identifying potential faults before they cause downtime—saving money and improving productivity.

For U.S.-based customers, these technological leaps mean Derui’s ultimate tensile strength testing machines don’t just meet current testing needs but are future-ready. Embracing these innovations helps manufacturers, labs, and R&D centers stay competitive and compliant in a fast-changing market.