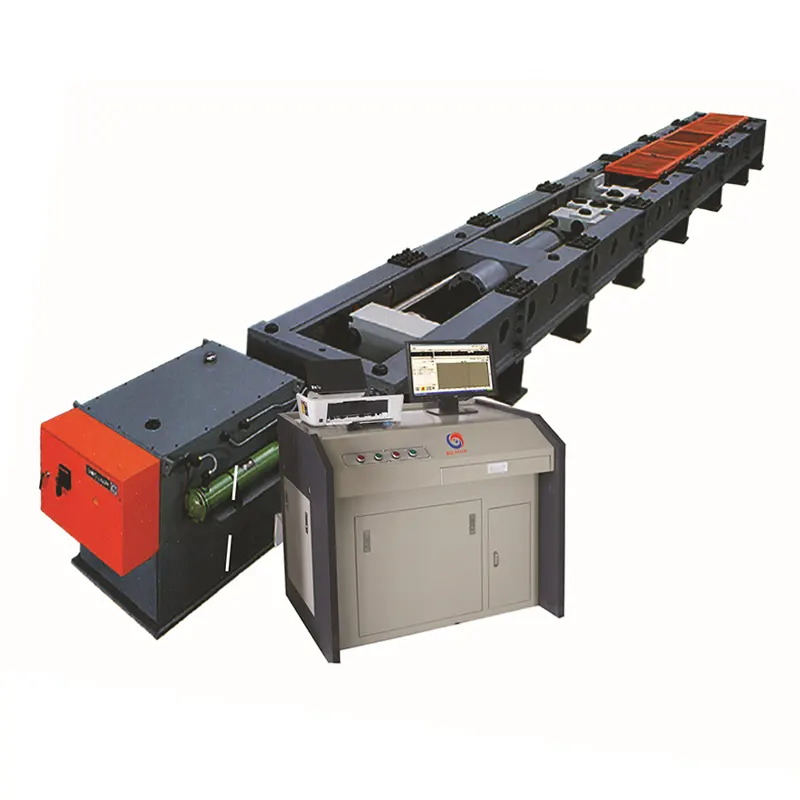

The three-seater sofa durability testing machine is a specialized testing device that simulates real usage scenarios, used to evaluate the structural stability, material durability and functional integrity of three-seater sofas during long-term use. The core objective is to accelerate the simulation of the load, friction, compression and other stresses that the sofa may withstand during daily use through standardized and repeatable mechanical actions, thereby predicting its service life, potential failure modes, and providing data support for product design optimization.

Experience top-notch testing with our Three Seats Sofa Durability Tester, designed for thorough examinations of quality and endurance. With a focus on performance, we ensure that every sofa undergoes rigorous testing to ascertain its durability and comfort. Our innovative approach employs advanced technology that simulates everyday usage stress, ensuring that your three seats sofa remains resilient for years to come. Reduce returns and enhance customer satisfaction with our sophisticated and reliable tester.

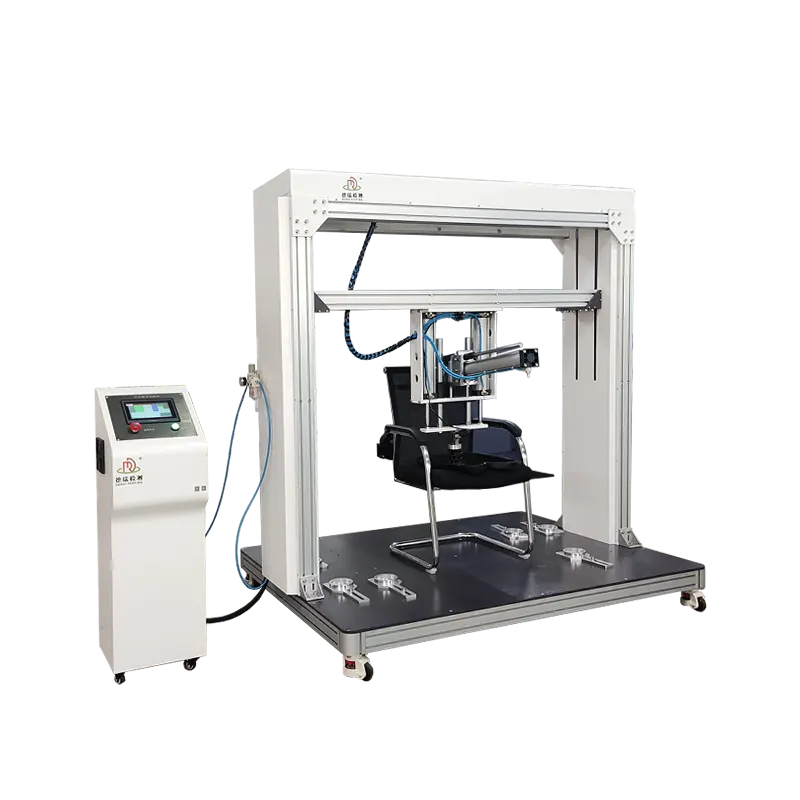

Main functions

1.This test method simulates daily usage conditions to examine the sofa's ability to withstand long-term repetitive loads. Test the durability of the seat, back and armrests of the sofa.

2.During the test, loading modules of a certain shape and mass are repeatedly loaded onto the surfaces of the seat, back and handrail respectively in the prescribed loading form and frequency.

3.The seat loading force is 750 Newtons and the back loading force is 400 Newtons. Test cycle: 25,000 to 200,000 times.

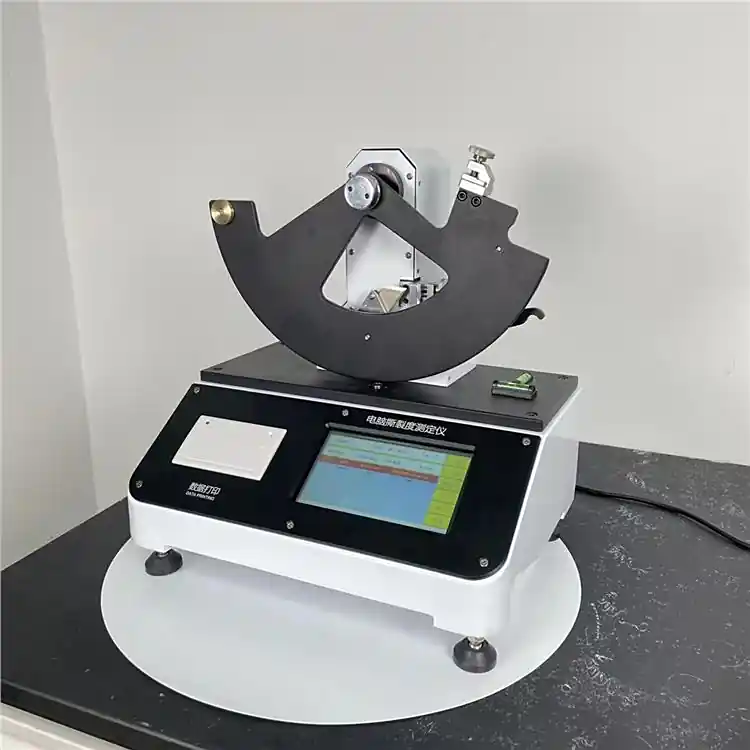

Control system

1.The touch screen is equipped with a PLC and features a power-off memory function.

2.This equipment is a multi-functional testing device that can select the output force or displacement of the cylinder.

3.It has a sample damage alarm and shutdown function. During the testing process, if the sample is damaged and touches the sensor, the machine will stop immediately.

4.The l servo proportional valve ensures stable and reliable output force of the cylinder, with digital display of the output force value of the cylinder.

Test purpose

- Check the internal quality and functional use of the furniture.

- Enable furniture products to establish a quality reputation in the minds of consumers.

- It is conducive to market occupation and the expansion of exports.

- It helps to design rationally, reduce material usage, improve production processes, enhance product quality and lower production costs.

- For producers and operators, it is necessary to understand the basic knowledge related to the mechanical property tests of furniture

- It is very beneficial and necessary for improving the management level of enterprises, ensuring product quality, developing new products and exploring new markets.

Test Procedure and Parameter Settings

Taking the standard GB/T 38467-2019 Soft Furnishings - Sofas as an example, the typical test procedure is as follows:

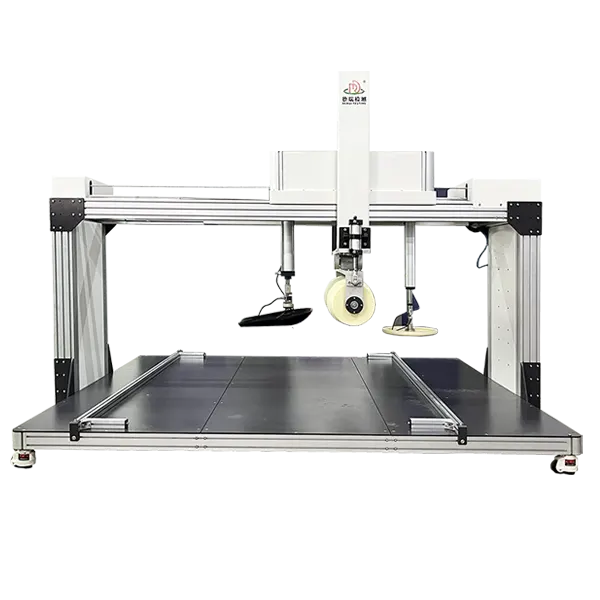

- Sample Preparation: Secure the three-seat sofa horizontally on the test machine platform, ensuring the frame aligns with the loading points.

- Parameter Configuration: Set the load (e.g., seating load = 1.2 times the designed load-bearing capacity), number of cycles (e.g., 10,000 cycles), and frequency (e.g., 2 cycles/minute) based on the product’s specifications.

- Initiate Testing: The loading system applies vertical/horizontal forces according to the preset program, while the friction unit operates synchronously (if required).

- Data Monitoring: Continuously record force-value curves, displacement changes, and abnormal signals (e.g., creaking from frame cracks or fabric tears).

- Termination Criteria: Stop the test upon reaching the preset number of cycles or when failure occurs (e.g., seat sinking exceeds 10 mm, or connection components detach).

esting Requirements and Design Logic

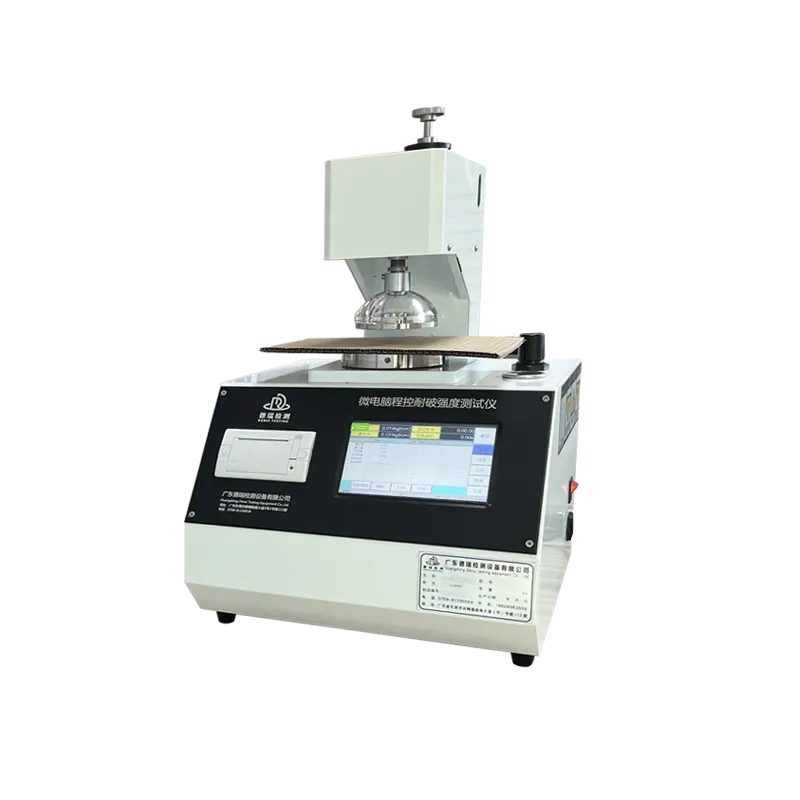

The durability of sofas directly impacts user experience and product reputation. As a commonly used piece of furniture in homes or public spaces, three-seat sofas must withstand complex stresses such as simultaneous multi-person sitting, frequent getting up and sitting down, and body leaning. Potential failure modes include:

- Frame deformation/fracture: Wooden/metal frames may bend or crack due to prolonged compression or impact.

- Filling material collapse: Materials like sponge or down may lose resilience after repeated compression, leading to a degraded seating feel.

- Fabric abrasion/tearing: Surface leather or fabric may develop pilling, fraying, or tears due to friction or pulling.

- Loosening of fasteners: Rivets, screws, or glued joints may fail due to vibration or stress concentration.

Based on these factors, the design of the test machine must replicate the primary stress scenarios experienced during actual use, such as sitting pressure, impact, and friction. It should also enable standardized testing through parametric control (e.g., load magnitude, frequency, and cycle count) to accelerate the simulation of long-term sofa usage.