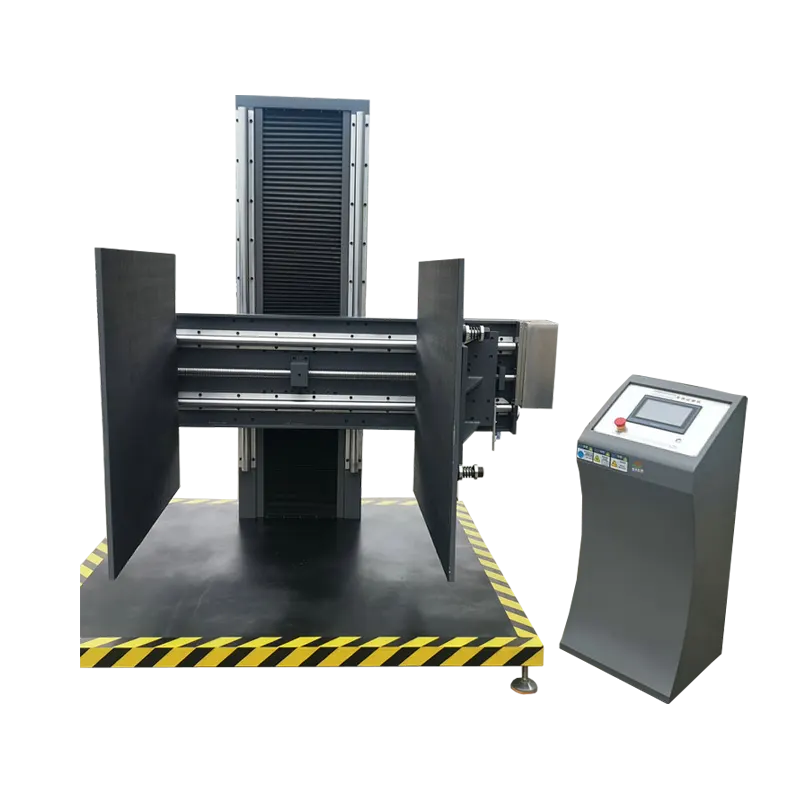

The packaging simulation transportation vibration table mainly simulates the situations when items encounter different road conditions during car transportation, such as bumps, uphill, downhill, and turns, etc. It simulates the collisions between items, the collisions between items and the car box, and the squeezing between items inside the car box, which may cause damage to the products. This helps to further improve the quality of the items and their packaging. It enables the acquisition of the actual working conditions' impact on the items in the laboratory, providing a basis for the evaluation or confirmation of the items and their packaging.

Equipment Principle

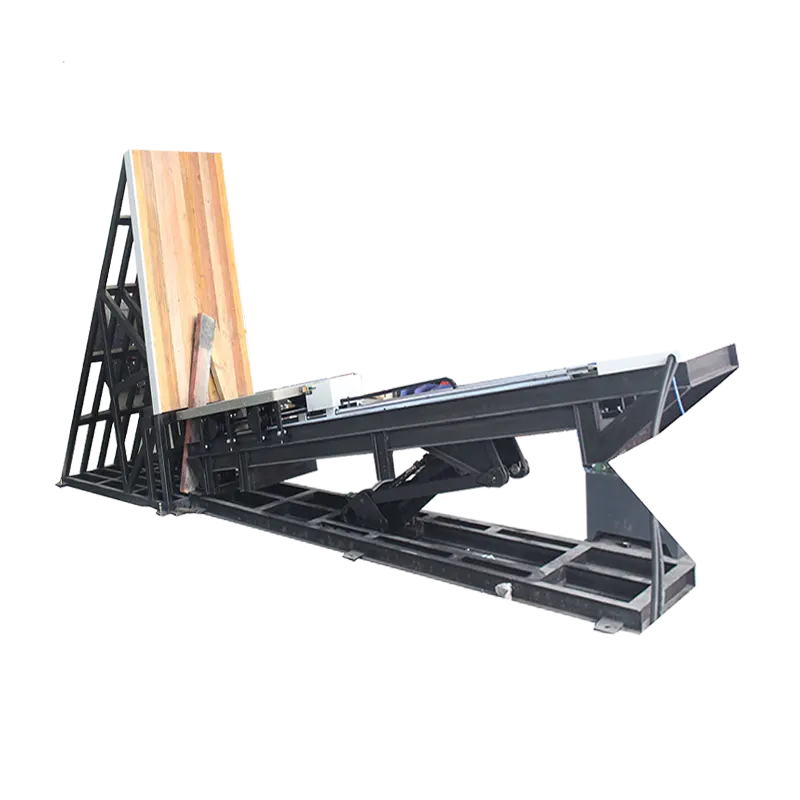

The horse-racing type vibration table is manufactured based on the transportation standards of the United States and Europe, and improved by referring to similar equipment from the United States. It simulates the vibration and collision of goods during transportation by automobiles or ships through the elliptical motion trajectory generated by the eccentric bearing during rotation. The test platform is fixed on the eccentric bearing. When the eccentric bearing rotates, the entire plane of the test platform will move up and down and back and forth in an elliptical motion. Adjusting the rotation speed of the eccentric shaft is equivalent to adjusting the traveling speed of the automobile or ship.

Equipment Features:

- The entire machine body of the carousel type box is treated with electrostatic baking paint. The worktable surface is made of SUS#304 stainless steel wear-resistant plate, with a reasonable design, a tight structure, and safe, stable, and accurate operation.

- The vibration frequency is displayed by a digital instrument and adjustable by a knob, with high precision.

- It adopts a silent belt drive, with low noise. The durable test fixture uses a guide rail type, making it convenient, stable, and safe to hold products.

- The machine is equipped with a heavy-duty channel steel base and anti-slip rubber pads at the four corners, making installation easy, operation smooth, and no need for installation of anchor bolts. The variable frequency motor speed regulation ensures smooth operation, strong load capacity, and long service life.

- It is equipped with aluminum profile guardrails and vibration frequency speed limit protection, making the test operation safer.

- Modified based on similar equipment in Europe and America, it features rotary vibration and complies with transportation standards in Europe and America. It is suitable for testing the packaging of products in the toy, electronics, furniture, gift, ceramic, and packaging transportation industries.

Equipment structure

- The load-bearing tabletop is made of SUS304 panel and steel plate.

- The test machine box is coated with DuPont powder paint from the United States, which is wear-resistant and elegant.

- The internal vibration of the machine adopts a stepless speed regulation control rail, which is solid and durable.

- The guardrail is made of aluminum profiles and channel steel with paint coating.

- The bottom is fixed with a 10mm channel steel frame.

- Fixed brackets are installed on both sides to prevent the vibration table from moving during long-term use.

Precautions:

- When loading the samples to be tested, make sure they are firmly fixed and the screw locks are tightened.

- If it is found during the test that the samples are not clamped tightly, stop the machine and re-clamp them firmly. Do not operate when the machine is still running.

- Place the test samples as close to the center as possible.

- The test samples must not exceed the worktable surface and must not be overloaded.