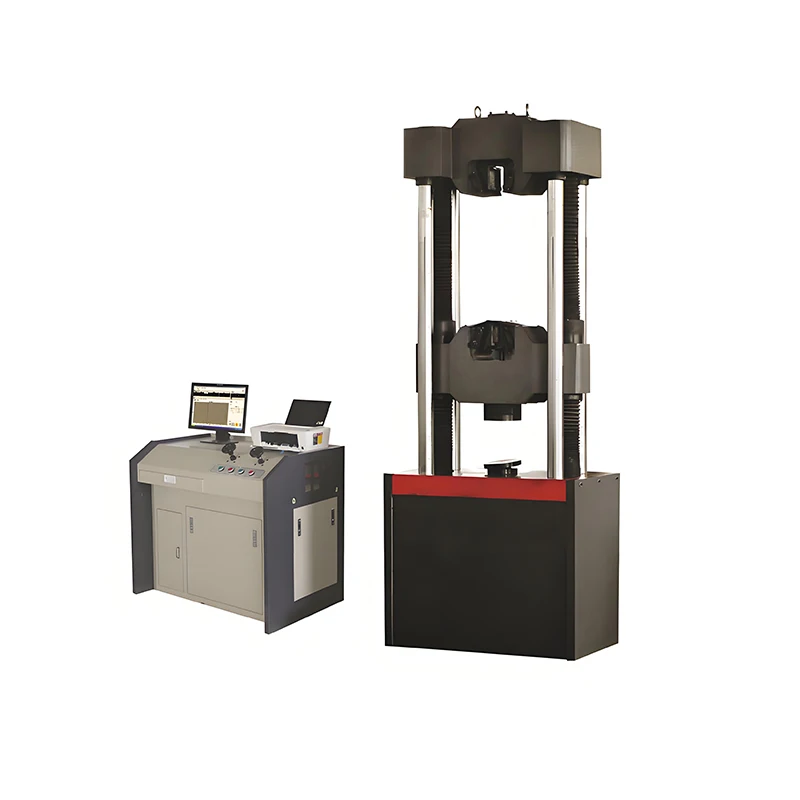

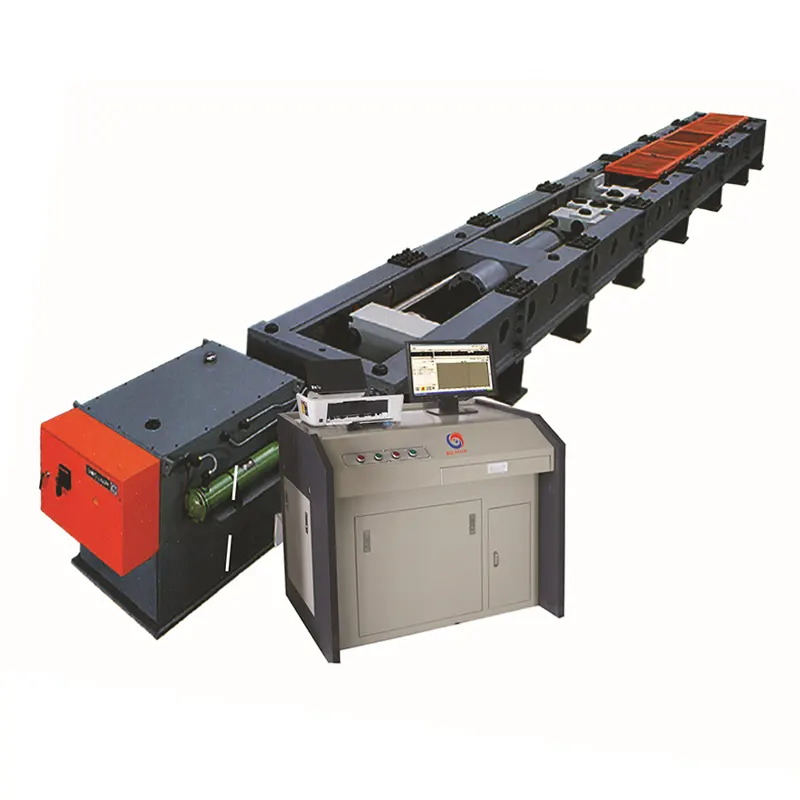

The computerized servo universal material testing machine is a high-precision and intelligent device for testing the mechanical properties of materials. It uses a computer-controlled servo motor (or hydraulic system) to drive the loading mechanism, applying standardized mechanical loads such as tensile, compressive, bending, and shearing to various materials including metals, non-metals, and composite materials. Accurately measure its key performance indicators such as tensile strength, yield strength, elastic modulus and elongation at break.

The computerized servo universal material testing machine adopts a high-speed DSP platform. It features high integration, powerful control and data processing capabilities, high reliability, and an adaptive PID algorithm for a fully digital, closed-loop (force, deformation, displacement) control system. It realizes fully digital closed-loop control of force and displacement, and can automatically switch between each control loop. When switching between different modes, it achieves a smooth and shock-free transition.

Test items: Tensile tests, structural strength tests, compressive tests, shear tests, bending tests, three-point bending tests, etc. for metal materials, fasteners, automotive parts and other products.

Applicable industries: This series of testing machines are widely used in material inspection and analysis in industries such as steel and metallurgy, mechanical manufacturing, fasteners, automotive parts, hardware tools, wires and cables, colleges and universities, scientific research laboratories, commodity inspection and arbitration, and technical supervision departments.

Features of the computerized universal material testing machine

The detachable fixture design ensures good compatibility and wide application

● Long-term update service for application systems and comprehensive data analysis and processing

● Desktop operating system software management and testing are simple and efficient to operate

It comes with a complete database kernel and provides professional standard algorithms

● Test plans can be set up according to different user needs

The aluminum extruded cover plate is equipped with a built-in double-roller screw and guide column design, which enhances the load efficiency and structural rigidity

The control system adopts high-response frequency servo motors, featuring sensitive and stable transmission, high precision and low noise

The desktop system software manages parameter setting, status control, data collection and processing analysis

It can be expanded with functions such as tension, compression, bending, folding and shearing, and can also perform various tests such as holding tension and compression and fatigue

● Interfaces for metal extensometers, displacement encoders and large deformation two-point extensometers are reserved to facilitate users' selection

The transmission mechanism is precisely designed with high-precision, gapless ball screws and synchronous belts, featuring excellent accuracy

Standard accessories

- Load sensor: High-precision load cell, one 10kN;

- Displacement sensing system: One set of high-precision photoelectric encoder for full-range displacement sensing;

- Data acquisition card: One TH2000 measurement control mainboard;

- Test software: One set of TM2101 English/Simplified Chinese/Traditional Chinese three-in-one measurement control system;

- Power system: One set of AC servo motor and control drive system;

- Transmission system: One set of domestic reducer and Taiwan precision lead screw transmission;

- Test fixtures: One set of tensile test fixtures;

Installation Requirements for the Equipment

- Installation Location:

- Install the equipment on a stable workbench or a flat, solid floor.

- Keep it away from doors, windows, or other areas with high air circulation.

- Environmental Conditions:

- Ensure there is no significant electromagnetic interference in the surrounding area.

- Protect the equipment from direct sunlight or proximity to air conditioning units.

- Temperature: Maintain an ambient temperature of 20±5℃, with hourly fluctuations of less than 2℃.

- Humidity: Relative humidity should not exceed 80%.

- Power Supply Requirements:

- Power Frequency: 50/60Hz.

- Voltage: AC 220±10V, 50Hz, with a power consumption of 3.0KW.

- Grounding: The power supply must have a grounding wire. Users should pay special attention to this requirement. The equipment is equipped with grounding protection; failure to use a grounded power supply may result in electric shock in case of leakage.

- Leveling Adjustment:

- Place a spirit level on the testing platform of the machine and adjust the four adjustable feet underneath to ensure the platform is perfectly level.

- Once the leveling is complete, the installation of the main unit is finished.