The test method of this machine is to load the specified weight on the object, and then impact the specimen at a speed of 30 times per minute and a stroke of 4 inches for 2,500 times. The test results can be used as a reference for quality improvement.

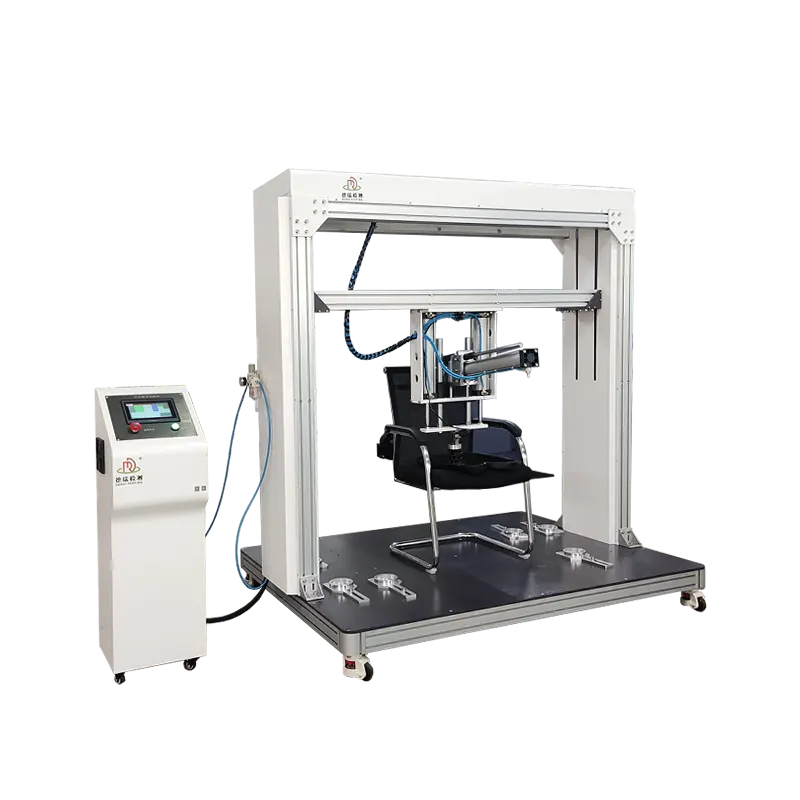

Our Office Chair Swivel Life Test Machine comes equipped with a range of advanced features that guarantee accurate testing for office chairs. Carefully designed to maximize effectiveness and efficiency, this machine ensures that each swivel mechanism is rigorously tested to meet industry standards. Whether it’s for quality assurance or product development, our machine is tailored to fit your needs. Tailored for precision engineering, it enhances productivity while reducing error margins. Discover the benefits of investing in robust testing solutions and ensure the long-lasting performance of your office chairs.

Main functions:

This testing machine is suitable for office chairs with a rotating seat surface, used to assess the chair's resistance to repetitive rotation pressure and wear.

1.The forward and reverse rotation angles can be set (45° to 355°).

2.Unidirectional 360° rotation.

Main technical parameters:

1. This equipment can perform tests in accordance with Bifma 5.1 standards, including single-direction or bi-directional rotation tests, or tests in both forward and reverse directions as per EN1335 standards.

2. It also allows for custom settings of test angles, rotation directions, and dwell times.

3. The rotating table diameter of this machine is 800 mm, and it can accommodate large seats up to 1000 mm in width.

4. The rotation speed is adjustable from 5 to 20 revolutions per minute.

5. Control mode: Programmable Logic Controller (PLC) with a large LCD display.

6. Cycle setting: 0 to 999,999 cycles.

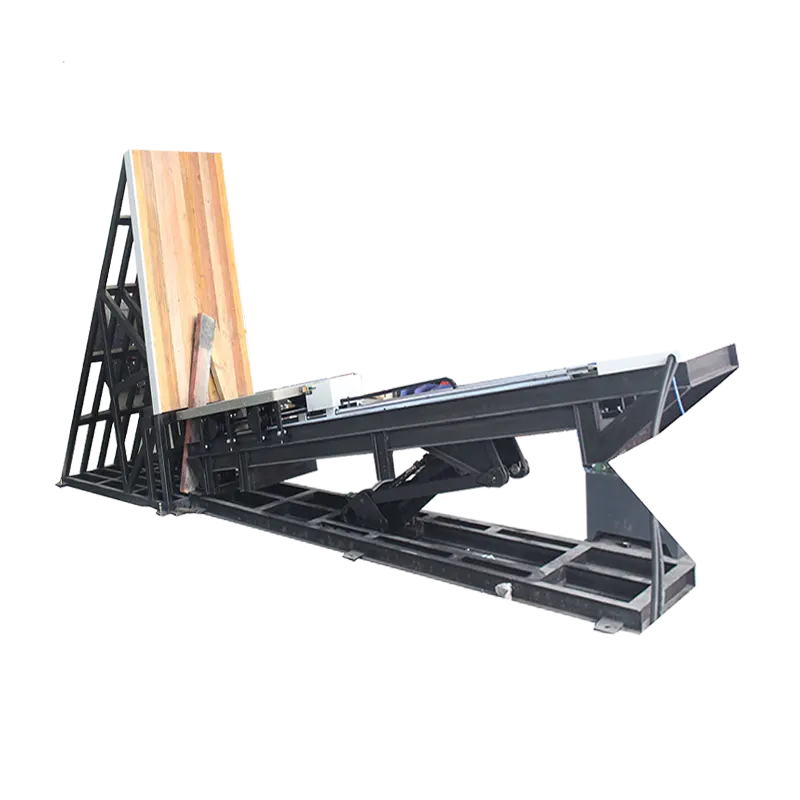

7. Accessories: A 113 kg weight and an electric lifting device for conveniently lifting heavy objects.

8. Voltage: Single-phase, AC220V; Power: 1KW.

Core advantages of the equipment:

Intelligent control

PLC programming enables fully automatic testing, with abnormal shutdown protection (such as force value exceeding limits, power failure data preservation).

High compatibility design

Adjustable fixtures adapt to different chair back shapes (curved surface / flat plate).

The lifting mechanism supports specimens with a seat height ranging from 300 to 700 mm.

Low-noise operation

Equipped with servo motor + planetary reducer, noise is reduced by 70%.

Safety protection

Multiple mechanisms such as cylinder stroke limit, emergency stop button, overload protection, etc. 17.

Maintenance Procedure:

1. Cleaning: Keep the machine clean at all times. Wipe the machine with a cotton cloth before and after each use to maintain its cleanliness.

2. Rust prevention: Spray anti-rust oil on the metal parts of the office chair testing machine once a week (wipe clean after 2 hours).

3. Lubricating oil: Regularly apply lubricating oil to the transmission parts of the machine (such as the screw) every month (ordinary lubricating oil is sufficient).

4. Maintenance: Regularly check whether the buttons on the control panel are functioning properly.