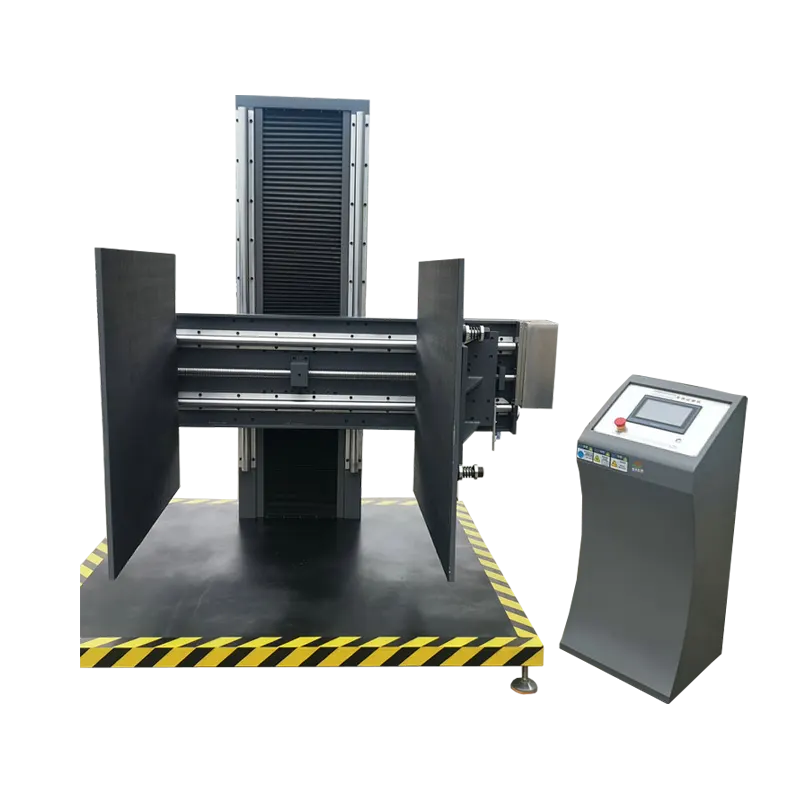

Our Three-Axis Electromagnetic Vibrating Table provides a comprehensive solution for your vibration testing needs. Incorporating cutting-edge technology and robust construction, we ensure exceptional performance for a variety of applications. Each feature is tailored to deliver optimal results, whether in laboratory settings or industrial applications.

Electromagnetic vibration test bench

Widely used in national defense, aviation, aerospace, communications, electronics, automobiles, home appliances, and other industries. This type of equipment is used to find early faults, simulate actual working conditions assessment and structural strength test. The product has a wide range of applications, a wide range of applications, and the test effect is remarkable and reliable. Sine wave, frequency sweep, frequency sweep, programmable, frequency multiplication, logarithm, maximum acceleration, amplitude modulation time control, full-featured computer control is simple, constant acceleration/constant amplitude r equipment has passed 3 months of continuous trouble-free operation, Stable performance and reliable quality.

Features of the equipment

Made of dense shell, small size, overtime sound work; the base of the machine is made of high-quality materials, easy to install, stable operation, no need to install anchor screws; digital control and display frequency of the control circuit, PLC adjustment function, make the equipment work more For stability and reliability; frequency sweep and fixed frequency operation mode, adapt to the test requirements of different industries; increase anti-interference circuit, solve the interference of control circuit due to strong electromagnetic field; increase working time setter, so that the test product can be connected to the accurate test time.

Instrument Features:

Different running direction of the vibration mode can work at the same time.

Intuitive control, easy to operate; fixed frequency, sweep frequency, program at any time convenient to switch;

With time timing, countdown display function.

Touch control controller, easy and convenient operation, to solve the shortcomings of the digital display operation inconvenience.

Control parameters real-time synchronous display, without human intervention.

Adopt vibration avoidance device, easy to install, smooth operation, without the need to install the ground fixing screws 6. Embedded amplitude prediction program and amplitude adjustment easily

Four-point synchronized excitation, table vibration uniformity.

Stepless adjustment of amplitude, fixed frequency and sweep frequency operation function to adapt to a variety of tests in different industries.

Increase anti-jamming circuitry to solve the strong electromagnetic fields due to the control circuit in the interference; 10 curve display function, at any time you can view the frequency waveform changes.

Curve support direct export function is strong.

Work running direction automatically switch.

Application scope

1、Product research and development and testing

Electronic products: In the research and development and production processes of electronic products such as mobile phones, tablet computers, and notebook computers, electromagnetic vibration tables can be used to simulate the vibration environments that the products may encounter during transportation and use. Through vibration testing, the firmness of the soldering of internal components of the product, the anti-vibration performance of the circuit board, and the stability of the shell structure can be detected, ensuring that the product can operate normally under various vibration conditions.

Automobile parts: Components such as the engine, transmission, suspension system, and seats of a car will be subject to varying degrees of vibration during driving. The electromagnetic vibration table can be used to simulate the vibration environment of these components under actual working conditions, conduct fatigue life tests, performance evaluations and quality control on them, and improve the overall 2、reliability and safety of the vehicle.

Aerospace equipment: Aircraft, satellites, rockets and other aerospace equipment will experience complex vibration environments during flight, such as ground vibrations during takeoff and landing, and aerodynamic vibrations during flight. The electromagnetic vibration table can be used to conduct vibration tests on the components and the entire machine of these devices, verifying their structural strength, reliability and anti-vibration performance, and ensuring that the equipment can operate safely in harsh vibration environments.

Standard

ISO 2247 packaging Full shipping packages and unit goods Fixed low frequency vibration test

ISO 13355 packaging - full, filled transport packaging and unit load - Vertical random vibration test

IEC 60068 basic environmental test procedures

ASTM d999 test method for vibration testing of shipping containers

ASTM d4728 random vibration test method for shipping containers

ASTM d3580 standard for product vibration test (vertical linear motion)

Software functions:

The independently developed CIMS + FCS is adopted for the shaking table software system, which can be expanded and configured with acceleration sensor and PC monitoring. The latest international vibration test standards are quoted to realize the selection of fixed frequency, sweep frequency, frequency doubling, program, logarithm and random vibration modes.