What is a Tensile Test

A tensile test is a fundamental materials testing method used to determine how a material behaves under tension. It involves applying a controlled pulling force to a specimen until it breaks. The primary purpose of tensile testing is to evaluate a material’s mechanical properties, ensuring it meets required standards for strength and performance.

Key parameters measured during tensile testing include:

- Tensile Strength: The maximum stress a material can withstand while being stretched before failing.

- Elongation: The extent to which the material stretches or elongates before breaking, indicating ductility.

- Yield Strength: The stress point at which a material begins to deform permanently.

Tensile testing is critical across various industries such as:

- Construction: Ensuring structural materials can handle load demands.

- Automotive: Testing components for durability and safety.

- Aerospace: Verifying materials withstand extreme conditions.

- Manufacturing: Maintaining quality control of raw materials and finished products.

These industries rely on accurate tensile data to design safer, stronger products and comply with regulatory standards.

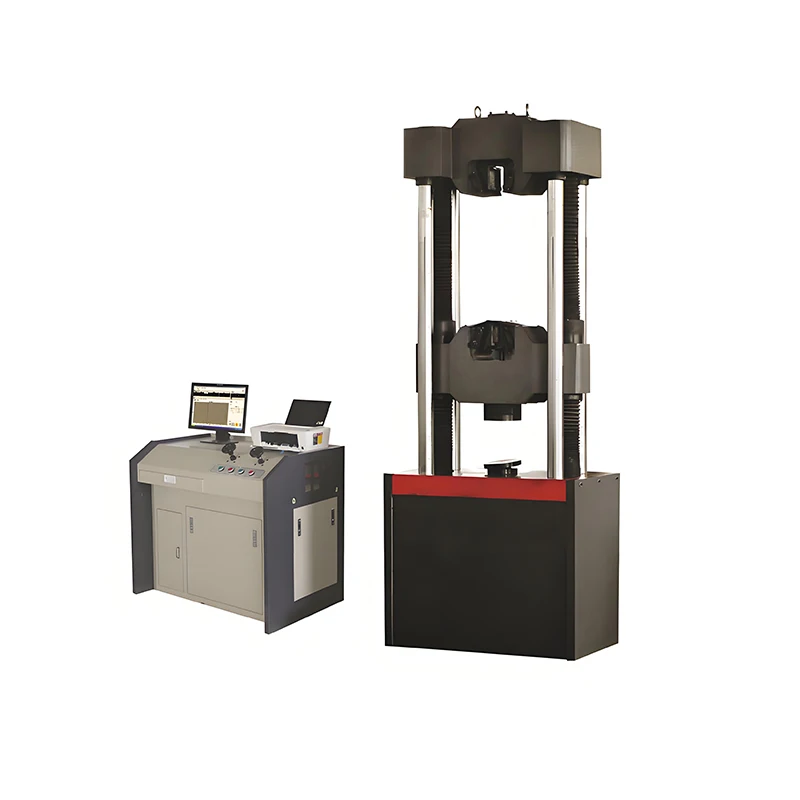

Understanding Universal Testing Machines UTM

A Universal Testing Machine (UTM) is a versatile device used to test the mechanical properties of materials. It’s called “universal” because it can perform a wide variety of tests, not just tensile tests. This flexibility makes it essential in labs and industries where different stress tests are required.

UTMs can perform several types of tests including:

- Tensile tests (measuring how materials stretch under tension)

- Compression tests (checking resistance to crushing forces)

- Bending tests (evaluating flexibility or stiffness)

- Shear tests (assessing material’s response to cutting forces)

The main components of a UTM include:

- Load frame: The sturdy structure that holds everything in place

- Grips: Devices that hold the test sample securely during testing

- Load cell: A sensor that measures the force applied to the sample

- Extensometer: Optional, measures the amount the sample elongates

- Control unit: The computer or interface used to control the machine and record data

Together, these parts allow for precise testing and reliable measurement of material properties to meet various ASTM and ISO standards commonly used in the U.S. market.

How Tensile Test is Conducted Using a Universal Testing Machine

Performing a tensile test using a universal testing machine (UTM) is a straightforward process that follows a few key steps to ensure accurate results.

Step by Step Procedure

- Sample Preparation

- Cut or shape the test material according to standards like ASTM or ISO.

- Ensure the sample dimensions and surface are clean and free of defects.

- Mark gauge length if necessary for elongation measurement.

- Setup in the UTM

- Securely place the sample between the grips of the UTM. Use the proper grips to prevent slipping or damage.

- Attach an extensometer if precise strain measurement is required.

- Calibrate the load cell and check that the machine is ready for testing.

- Running the Test

- Start the machine’s crosshead movement to apply a tensile load gradually.

- Monitor the test through the control unit and software as the machine records load and elongation data.

- The test continues until the sample breaks or reaches a predefined condition.

- Data Acquisition and Interpretation

- The UTM records key parameters like tensile strength, yield strength, and elongation.

- Generate a stress-strain curve to visualize material behavior during the test.

- Analyze results to assess if the material meets quality or design requirements.

Safety Considerations

- Always wear safety glasses and protective gear around the machine.

- Keep hands clear of moving parts and grips during testing.

- Regularly inspect grips and fixtures for damage to prevent accidents.

- Follow manufacturer guidelines and standard protocols to avoid sample ejection or machine overload.

This process holds true for universal testing machines across industries, delivering reliable tensile strength testing for materials used in construction, automotive, aerospace, and more.

Key Features to Consider When Choosing a Tensile Test Universal Testing Machine

Selecting the right tensile test universal testing machine (UTM) is crucial for accurate results and smooth operation. Here are the key features to keep in mind:

Load Capacity and Accuracy

- Choose a UTM with a load capacity that matches your testing needs, whether small samples or heavy-duty materials.

- Look for high accuracy in load measurement, typically with a precise load cell, ensuring reliable tensile strength data.

Software and Data Analysis Capabilities

- Opt for UTMs with user-friendly software that offers real-time data display, automated calculations, and easy export options.

- Advanced data analysis tools help interpret tensile strength, yield strength, elongation, and generate stress-strain curves effortlessly.

Types of Grips and Fixtures Compatible

- Compatibility with various grips and fixtures is essential for testing different materials like metals, plastics, or composites.

- Check if the machine supports custom or standardized grips that fit your sample types and sizes.

Compliance With International Standards ISO and ASTM

- Ensure the UTM meets global tensile test standards such as ISO and ASTM for trustworthy, repeatable testing results.

- Compliance is especially important if your testing supports certification, quality control, or regulatory requirements.

Durability and After Sales Service

- Look for machines built with robust materials for long-lasting performance in busy laboratories or production environments.

- A strong after sales service network is key—choose a supplier like Derui, known for fast support, calibration services, and maintenance programs tailored to the U.S. market.

| Feature | What to Look For | Why It Matters |

|---|---|---|

| Load Capacity | Match range to your samples | Accurate and safe testing |

| Accuracy | High precision load cell | Reliable tensile strength data |

| Software | Easy interface, data export, analysis tools | Simplifies reporting and decisions |

| Grips & Fixtures | Variety to fit materials | Versatility and proper sample holding |

| Compliance (ISO/ASTM) | Certified testing standards | Validates results and regulatory needs |

| Durability & Service | Sturdy build, local support, maintenance options | Minimizes downtime, extends machine life |

Choosing the right tensile testing machine balancing these features ensures your lab or facility runs smoothly while producing consistent, trusted results.

Applications of Tensile Test UTMs Across Industries

Tensile test universal testing machines (UTMs) play a crucial role across many industries in the United States. They help ensure materials and products meet strict quality and safety standards.

Material Quality Control

UTMs are widely used for routine quality checks on raw materials and finished products. They make sure materials like metals, plastics, and composites maintain consistent tensile strength and elongation—key for safety and durability in construction, automotive, and manufacturing sectors.

Research and Development

In R&D, tensile tests provide valuable data to develop new materials and improve existing ones. Engineers rely on tensile strength testing equipment to study mechanical properties and fine-tune formulations. This helps in creating stronger, lighter, and more reliable products.

Failure Analysis and Product Design

When products fail in real life, tensile testing helps identify the root cause by measuring mechanical limits. It guides design changes to prevent future breakdowns, improving overall product performance. Designers use data from tensile tests to predict material behavior and ensure products meet expected loads.

Certifications and Regulatory Compliance

Meeting ASTM and ISO tensile test standards is mandatory in many industries. Universal testing machines help companies comply with these regulations by providing accurate, traceable results. This boosts customer confidence and helps companies pass audits and certifications required in aerospace, automotive, and construction industries.

Why Choose Derui for Your Tensile Test Universal Testing Machine Needs

When it comes to tensile test universal testing machines, Derui stands out for its strong product range and technical know-how. Whether you need a basic model or advanced equipment for complex materials testing, Derui offers solutions that combine accuracy with durability.

Derui’s Product Line and Expertise

- Wide range of machines from desktop models to high-capacity load frames.

- Supports multiple test types including tensile, compression, bending, and shear.

- Precision engineering ensures consistent, reliable test results every time.

- Compliance with ASTM and ISO standards for laboratory and industrial use.

Innovative Technology and Precision

- Electro-servo control systems for smooth, precise load application.

- Integrated extensometer compatibility for accurate strain measurements.

- Advanced software that simplifies data analysis and generates detailed reports.

Local Service and Support Options

- Prompt technical assistance available across the U.S.

- Quick access to spare parts and upgrades.

- Training and installation support tailored to your team.

| Feature | Benefit |

|---|---|

| Electro-servo system | Accurate load control |

| Extensometer-ready | Detailed strain data |

| U.S.-based service | Fast, reliable customer support |

| Custom software | Easy data collection and reporting |

Derui’s focus on quality, innovation, and customer care makes it a smart choice for anyone investing in tensile strength testing equipment.

Maintenance Tips for Your Tensile Test Universal Testing Machine

Keeping your tensile test universal testing machine in top shape ensures consistent, accurate results and extends its lifespan. Here are some essential maintenance tips:

Regular Calibration and Inspection

- Calibrate routinely to maintain accuracy, ideally once a year or as recommended by ASTM or ISO standards.

- Inspect load cells and extensometers for any signs of wear or damage. Faulty sensors can skew your tensile strength testing results.

- Check software updates to keep data analysis tools running smoothly and compliant with the latest standards.

Proper Handling and Storage of Grips and Fixtures

- Always clean grips and fixtures after each test to avoid material buildup that can affect grip performance.

- Store components in a dry, dust-free environment to prevent rust or corrosion.

- Handle carefully to avoid bending or damaging grips, which could cause uneven stress during tests.

Troubleshooting Common Issues

- If your UTM shows inconsistent results, verify calibration and inspect for loose connections.

- Address unusual noises or movements by checking the load frame and motor systems.

- For software glitches, restart the control unit and ensure the latest driver or software versions are installed.

Regular maintenance maximizes your machine’s reliability and helps your tensile testing run smoothly every time.

Frequently Asked Questions about Tensile Test and UTMs

Here are answers to some common questions about tensile testing and universal testing machines (UTMs), whether you’re just getting started or have some experience.

What is a tensile test used for?

It measures how a material reacts when stretched, helping you find its tensile strength, yield strength, and elongation at break.

How do I prepare a sample for a tensile test?

Samples need to have specific shapes and sizes following ASTM or ISO standards. Make sure the edges are smooth and the sample fits properly in the grips.

What is a universal testing machine?

A UTM is a versatile device that can perform tensile, compression, bending, and shear tests on materials. It’s called “universal” because of its ability to handle different test types.

How do I operate a tensile test machine?

Place the prepared sample in the grips, configure test settings on the control unit, run the test, and then analyze the data provided, such as the stress-strain curve.

What safety precautions should I take when using a UTM?

Always wear safety glasses, keep clear of moving parts, and ensure the sample is securely gripped to prevent unexpected breakage or flying fragments.

How often should I calibrate my UTM?

Calibration should be done regularly, typically every 6 to 12 months, to maintain accuracy and comply with testing standards.

What grip types work best for tensile testing?

Choose grips compatible with your sample material and shape, such as wedge grips for metals or pneumatic grips for plastics, to prevent slipping or damage.

Can a UTM test both metals and plastics?

Yes, universal testing machines are designed for both metallic and non-metallic materials when equipped with the right grips and fixtures.

What software features should I look for in a tensile testing machine?

Look for software that offers real-time data display, automatic calculations for key properties, and easy reporting options compliant with ASTM or ISO standards.