Material Strength Testing: Your Complete Guide to Universal Testing Machines (UTMs)

Derui designs and manufactures precision Universal Testing Machines (UTMs) that form the core of any material strength testing laboratory. Engineered to deliver uncompromising accuracy in tensile, compression, flexure, and shear testing, our systems comply with ASTM, ISO, and EN standards. Whether you are certifying raw materials, validating components, or conducting advanced R&D, our solutions provide the reliable data you need to make confident decisions.

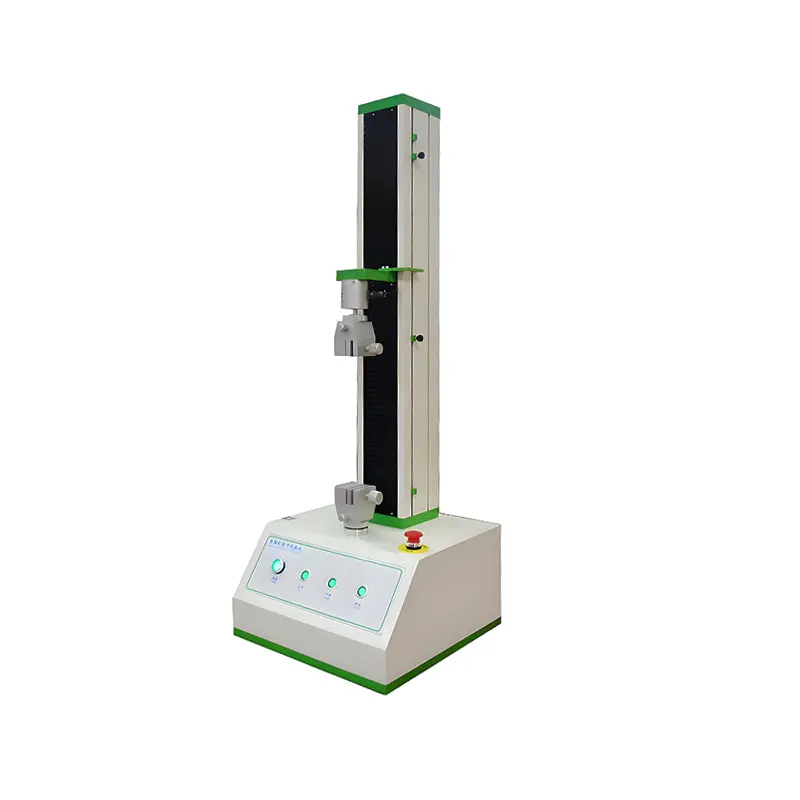

Ideal for quality control labs, educational institutions, and R&D with space constraints. These single-column material strength testers deliver precise results for tensile tests on polymers, compression tests on foams, and three-point bend tests on composites, all on a compact benchtop footprint.

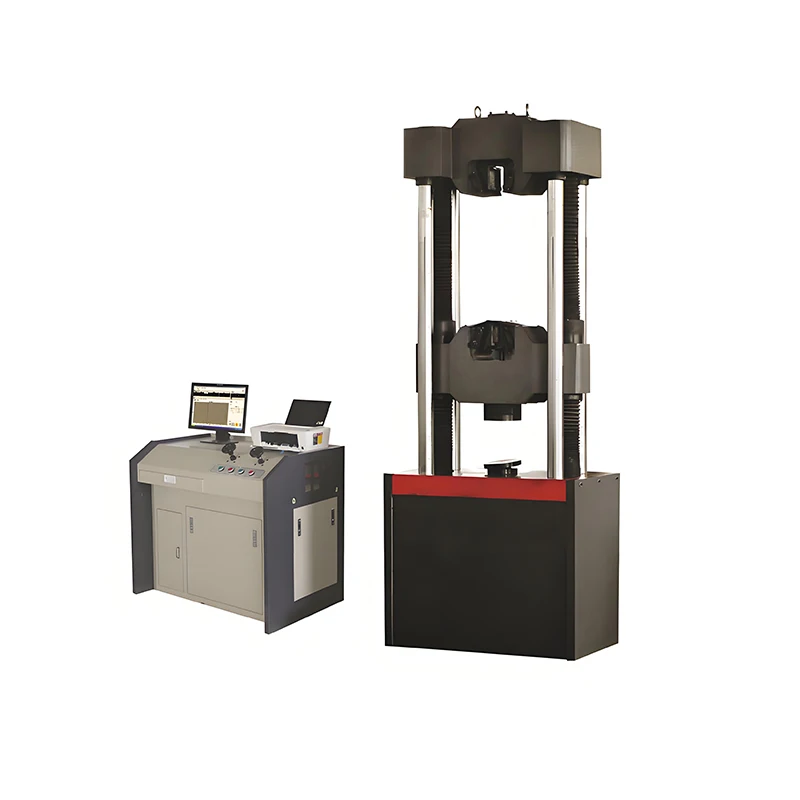

Our dual-column UTMs provide the frame stiffness and alignment accuracy essential for testing metals, high-strength composites, and critical components. They are the workhorse for high-volume QC and advanced research, performing everything from high-force tensile tests to precise modulus measurement in compression and flexure.

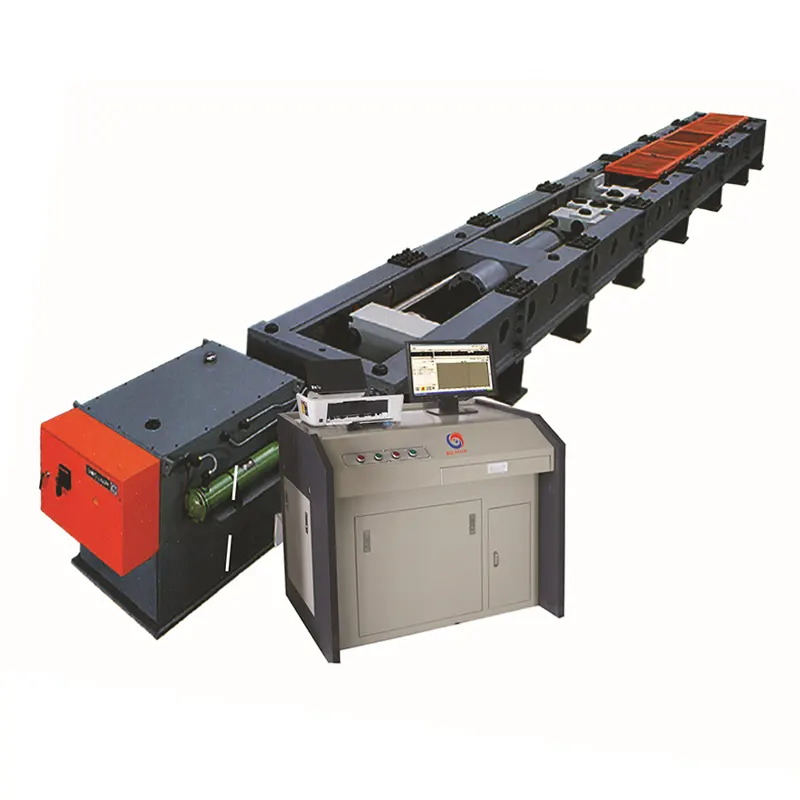

When your material strength testing requires forces up to 5,000 kN for construction materials, large industrial parts, or heavy-duty fasteners, our servo-hydraulic systems deliver precise, controlled loading. These are true universal testing machines capable of the most demanding tensile, compression, and large-scale flexure tests.

-

A True Universal Testing Platform: One Derui UTM can perform tensile (ASTM E8), compression (ASTM E9), flexure (ASTM D790), and shear tests with a simple change of fixtures, maximizing your return on investment.

-

The Foundation of Accuracy & Repeatability: A high-rigidity load frame, precision-ground ball screws, and traceably calibrated high-accuracy load cells work in concert to ensure data integrity for every test.

-

Future-Proof Modular Design: Start with a core system and seamlessly integrate advanced accessories later—such as video extensometers, environmental chambers, or hundreds of specialized fixtures—to adapt to new testing standards.

-

Direct Manufacturer Support & Lifecycle Partnership: We provide end-to-end partnership—from application consulting and custom configuration to installation, training, and periodic calibration—ensuring your lab operates at peak performance long-term.

As a direct manufacturer, we engineer solutions tailored to your specific materials, standards, and throughput needs. Complete the form below to describe your requirements. Our engineering team will review your needs and contact you to discuss a customized system proposal.

Material strength testing is the process of determining a material's mechanical properties by applying controlled forces until deformation or failure. The Universal Testing Machine (UTM) is the core device for these tests, encompassing:

-

Tensile Testing: Measures resistance to pulling forces (ASTM E8, ISO 6892).

-

Compression Testing: Measures resistance to crushing forces (ASTM E9, ISO 604).

-

Flexure (Bend) Testing: Measures resistance to bending forces (ASTM D790, ISO 178).

-

Shear & Peel Testing: Measures interlayer or adhesive bond strength (ASTM D1002, D903).

How a Modern UTM Works: The process is a streamlined digital workflow:

1) Fixturing: A specimen is secured in the correct grips or platens.

2) Configuration: The test method (e.g., ASTM standard) is selected in the software.

3) Controlled Loading: The drive system applies precise force while the load cell and extensometer capture data in real-time.

4) Automatic Analysis: Software generates a stress-strain curve and calculates key properties (like tensile strength, yield strength, modulus of elasticity), delivering a complete report.

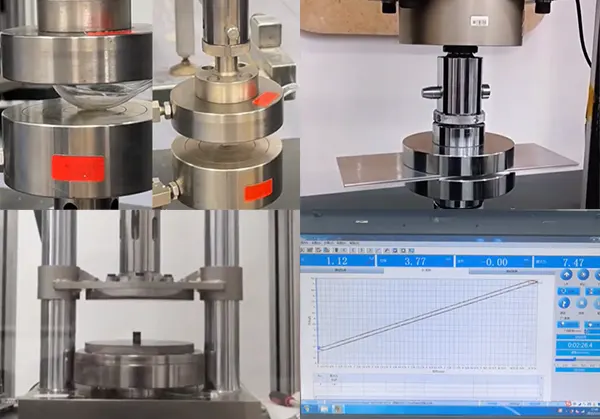

Compression Testing: Evaluating Crushing Strength & Stability

A complete understanding of material performance requires testing under forces that mimic real-world conditions, including compression. Accurate compression testing is a fundamental capability of any true Universal Testing Machine (UTM), essential for characterizing materials like concrete, metals, foams, and composites under crushing or buckling loads.

Executing a Standardized Compression Test

Conducting a compression test on a Derui UTM is a straightforward process that leverages the system's core precision. The machine is configured with flat or specialized compression platens suited to the specimen, such as concrete cylinders or polymer blocks. Utilizing the same high-rigidity load frame and calibrated measurement system, the UTM then applies a controlled, axial compressive force. Relevant standards, such as ASTM E9 for metals or ISO 604 for plastics, are integrated into the control software, ensuring the test is performed with compliant methodology and delivering reliable, certifiable data.

The Integrated Derui Solution

This inherent flexibility underscores the value of a unified testing platform. With a Derui UTM, your laboratory gains the ready capability to perform precise compression tests alongside tensile, flexure, and shear tests. This eliminates the need for separate, dedicated compression testers, maximizing both your equipment investment and your lab’s comprehensive material evaluation capacity.

Why Material Strength Data Drives Confident Decisions

Comprehensive material strength testing is more than a laboratory procedure; it is the foundation of risk mitigation, product validation, and innovation. The data generated—from tensile strength and modulus to compressive resistance and flexural performance—provides the objective evidence needed for critical decisions across the product lifecycle.

From Material Selection to Finished Product

This data guides engineers in selecting the right material for an application, validates that components can withstand real-world forces, and certifies that final products meet stringent industry standards. Inconsistent or unreliable test results can lead to under-engineering, product failure, recalls, or compliance failures.

The Non-Negotiable Requirement: Accuracy & Repeatability

Therefore, the precision and repeatability built into your testing equipment are non-negotiable. Every variable—from the rigidity of the load frame and calibration of the sensors to the compliance of the test method with ASTM, ISO, or EN standards—must be controlled to ensure data integrity.

Derui systems are engineered to be the reliable source of this critical data. Our Universal Testing Machines deliver the accurate, standards-compliant results that engineers and scientists rely on to ensure product safety, optimize designs, and build unwavering trust in their supply chain.

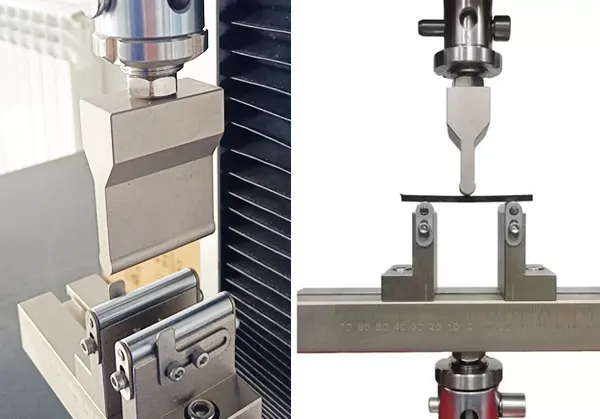

Flexure Test: Measuring Bending Strength & Stiffness

While tensile strength is fundamental, many real-world components—from structural beams and automotive parts to plastic housings and medical blades—are designed to resist bending stress. A comprehensive material strength testing program must therefore include precise flexure (bend) testing.

Conducting a Compliant Bend Test

The test is performed on your Universal Testing Machine (UTM) by using a dedicated flexure fixture. The specimen is placed on two support rollers, and a loading nose applies force at the midpoint (3-point bend) or two points (4-point bend). Standards like ASTM D790 and ISO 178 define the precise methodology for materials like plastics and composites. The UTM’s software is critical here, allowing exact configuration of support span, test speed, and data collection to ensure full compliance.

The Derui Advantage: Integrated Testing Capability

With a Derui UTM, converting your system for bend testing is a seamless process. This inherent modularity exemplifies the true “universal” nature of our equipment. By simply installing the appropriate fixtures, you expand your laboratory’s capability to perform standardized bend tests, achieving comprehensive material characterization without the cost and complexity of dedicated, single-function machines.

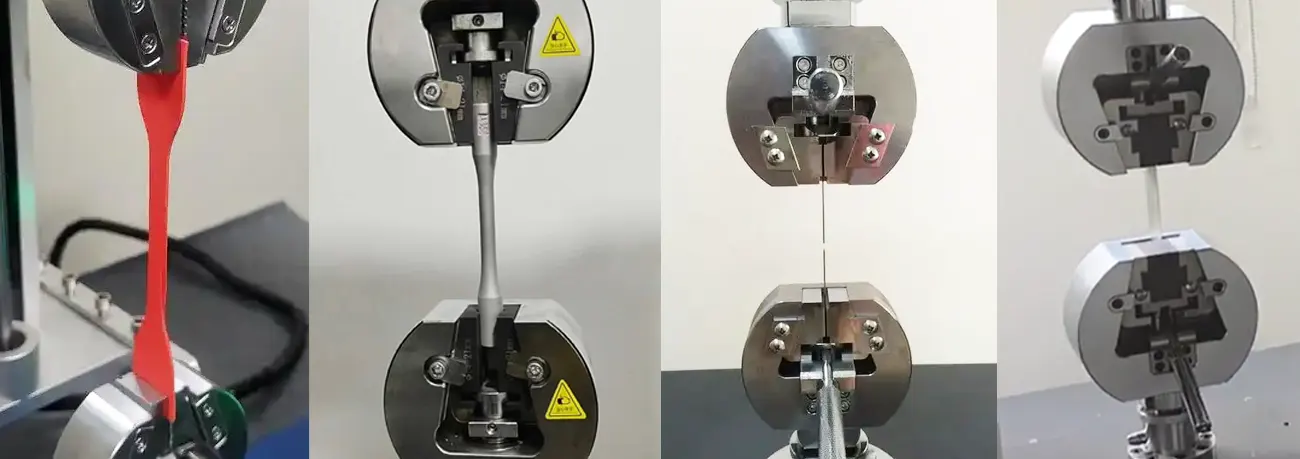

Wedge Grip

The ultimate grip for high-strength metals

Pneumatic Grip

Fast, automated gripping for high-volume testing.

Threaded Grip

Uniform pressure for delicate or composite materials.

Shear Fixture

Specialized tool for measuring shear strength.

DR-L201 Desktop tensile testing machine

The DR-L201 desktop tensile testing machine is a compact, cost-effective benchtop solution for precise tensile, compression, and flexure tests. Fully compliant with ASTM and ISO standards, it delivers reliable performance for quality control, educational labs, and R&D on low to medium-force materials like polymers, textiles, and thin metals.

Can one machine test metals, plastics, and composites?

Yes. By changing fixtures and parameters, a single UTM can accurately test tensile, compression, and flexural properties of almost any solid material.

How to choose the right material strength testing machine for my lab?

Focus on your maximum force requirement, material types (metals, plastics, composites), and required tests (tensile, compression, flexure). Consider future needs and choose a modular Universal Testing Machine (UTM) that can expand. Our guide on “7 Key Factors When Choosing Material Strength Testing Equipment” provides a detailed checklist.

What is the best universal testing machine for metals testing?

For accurate metals testing (yield strength, tensile strength), you need a high-rigidity, floor-standing UTM with precise alignment and high-capacity load cells. Machines compliant with ASTM E8/ISO 6892 are essential. Explore our [Floor-Standing UTMs] for models designed specifically for metals and high-strength materials.

Can I test plastics and polymers on the same machine as metals?

Absolutely. A true Universal Testing Machine (UTM) is designed for this. By switching to appropriate grips (e.g., roller grips for plastics) and using the correct standards (e.g., ISO 527 for plastics), one Derui UTM can accurately test everything from soft polymers to hard metals.

What is the difference between a tensile test and a compression test?

A tensile test pulls a specimen apart to measure its resistance to stretching. A compression test crushes or pushes a specimen to measure its resistance to crushing or buckling. Both are fundamental tests performed on the same UTM by changing the fixtures.

What affects the price of a universal testing machine?

Key factors are: force capacity (kN), frame rigidity, measurement accuracy (load cell grade), sophistication of the control software, and included accessories. A basic benchtop tester is a cost-effective entry point, while a high-capacity, fully automated servo-hydraulic system with advanced analysis software represents a premium investment.

How important is software in a material testing system?

The software is the “brain” of the system. It controls the test, collects data, ensures standard compliance, and generates reports. Look for intuitive software that preloads test methods, allows custom analysis, and exports data easily for traceability and quality documentation.

Do you provide fixtures for non-standard or custom sample shapes?

Yes. As a direct manufacturer, we specialize in custom fixture design for unique components, fasteners, textiles, or biomaterials. Our modular ecosystem allows us to engineer solutions for your specific gripping and fixturing challenges.

What after-sales support can we expect?

We provide comprehensive support: installation & on-site training, detailed operational manuals, annual calibration services, a readily available spare parts inventory, and ongoing technical support via email, phone, or remote session to ensure your lab’s continuous operation.