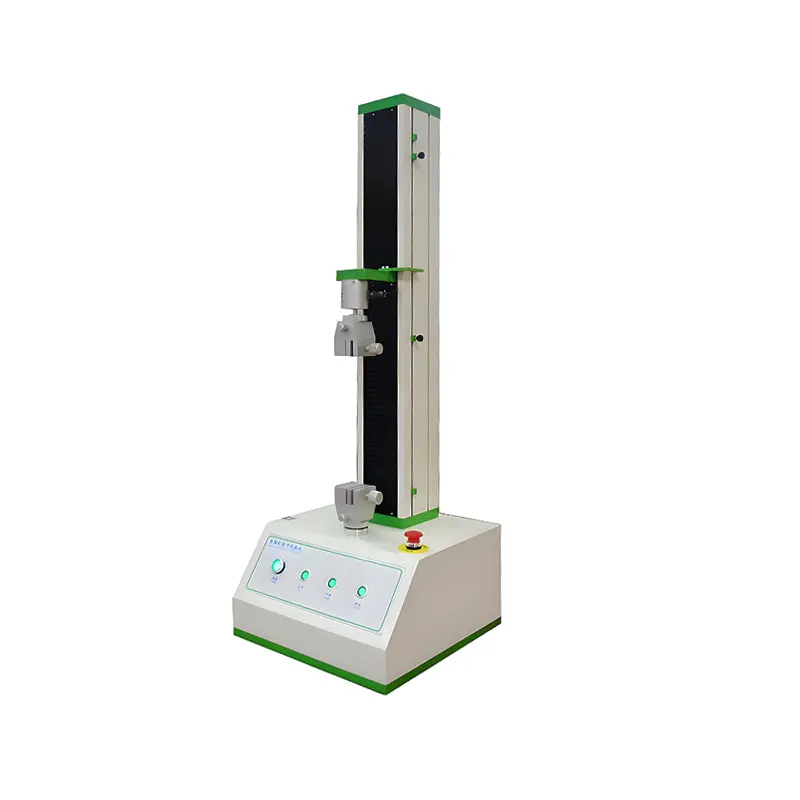

This page details our range of small tensile testers—encompassing mini and benchtop universal testing machines (UTMs)—precisely engineered for the needs outlined in our main product line: delivering uncompromising accuracy for laboratories where space and budget are defining factors.

Whether you call it a mini tensile tester, a compact UTM, or a benchtop system, these instruments are designed to provide full compliance with ASTM, ISO, and other international standards for testing polymers, textiles, thin metals, adhesives, and electronic components. They are the cornerstone of efficient quality control (QC), research & development (R&D), and educational laboratories worldwide.

Explore our curated selection of compact, benchtop universal testing machines. Each model, from mini to standard small tensile testers, is built with Derui’s commitment to precision, durability, and user-centric design, backed by comprehensive global support.

One:Fundamentally Space-Saving: The compact benchtop design of our mini UTMs turns any available work surface into a fully functional test station, eliminating the need for dedicated floor space.

Two:Optimized for Value & ROI: Achieve laboratory-grade precision and global standard compliance at a highly accessible price point, offering exceptional return on investment for routine testing.

Three:Engineered for Ease of Use: Intuitive software and straightforward mechanical design ensure operators can be productive quickly, minimizing training time and reducing the potential for user error.

Four:Surprisingly Versatile & Modular: Don’t let the small size fool you. These systems are built on a modular platform, readily accepting a wide array of grips, fixtures, and extensometers to handle diverse sample types and test methods.

A benchtop tensile tester is a compact, single-column universal testing machine (UTM) specifically engineered to perform precise tension, compression, and flexure tests on materials and components, all within the footprint of a standard laboratory workbench. It is the definitive embodiment of a small or mini tensile tester, delivering the same core functionality and standards compliance as larger floor-standing systems, but optimized for laboratories where space efficiency and cost-effectiveness are paramount.

The essence of a benchtop UTM lies in its integrated design: a robust load frame, a precision drive system, a high-accuracy load cell, and intuitive control software are all contained within a single, space-saving unit. This makes it an indispensable compact lab equipment for QC, R&D, and educational settings focused on polymers, textiles, thin metals, wires, and other low-to-medium force applications.

The operation of a small tensile tester mirrors the fundamental principles of materials testing but within a streamlined, user-friendly package. Here’s a step-by-step overview:

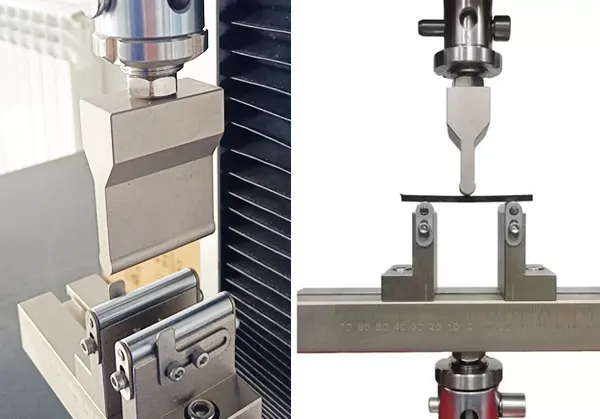

Sample Preparation & Mounting: A standardized specimen is securely clamped using grips appropriate for the material (e.g., wedge grips for metals, pneumatic grips for composites). The benchtop design allows for easy front access to the test area.

-

Test Configuration: The operator uses the intuitive software to select the test standard (e.g., ASTM D638) or define custom parameters like test speed and target displacement. This software is the “brain” of the mini UTM.

-

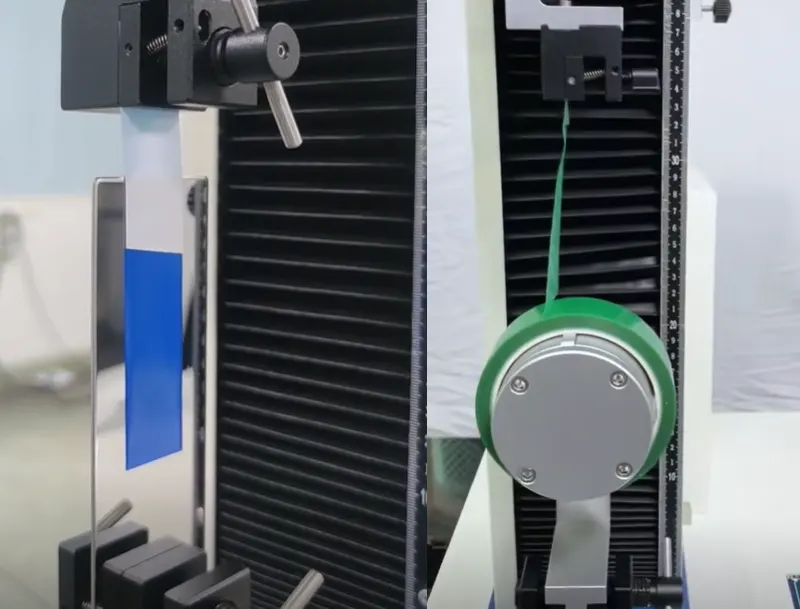

Controlled Force Application: Upon starting, the precision electromechanical drive system moves the crosshead at a constant rate, applying a controlled tensile (pulling) force to the specimen. The compact frame ensures exceptional alignment and stability during this process.

-

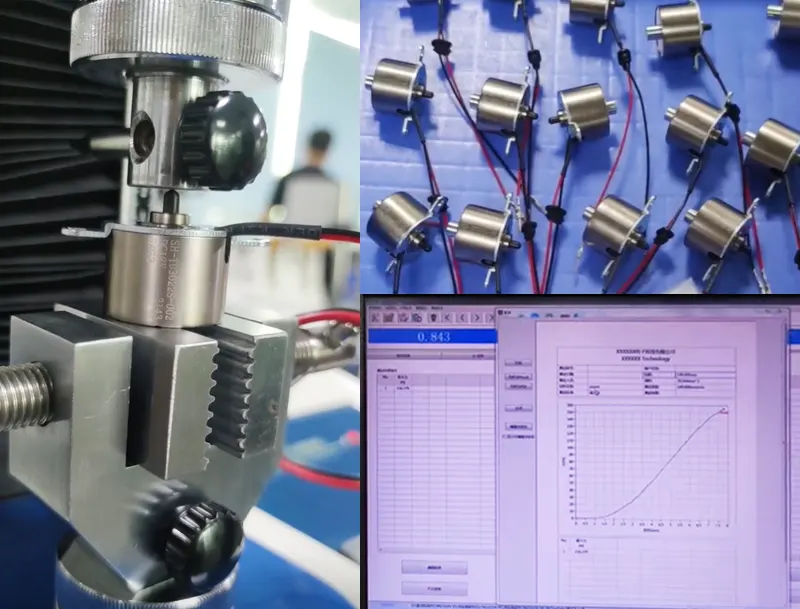

High-Accuracy Data Acquisition: As the specimen stretches, a calibrated load cell measures the force with high resolution, while an optional extensometer precisely records elongation. In a benchtop tester, this sensor technology is miniaturized without compromising accuracy.

-

Automatic Analysis & Reporting: The software records the force vs. elongation data in real-time, automatically generating a stress-strain curve and calculating key results such as tensile strength, yield point, and modulus of elasticity. This seamless process makes the compact UTM both powerful and easy to use.

This efficient workflow demonstrates how a Derui benchtop tensile tester transforms physical samples into reliable, actionable data, all from your laboratory bench.

Flexure (Bend) Testing for Small Components

Evaluate a material’s stiffness and strength when subjected to bending forces, a critical property for many structural applications.

Typical Applications: Determining the flexural modulus and strength of plastic bars, insulating materials, small-diameter rods, prototype composite beams, and brittle materials.

How It Works: Using a three-point or four-point bend fixture, the specimen is supported at two points while the machine applies a downward force at the center(s). The software calculates key bending properties from the force-deflection curve.

Standards & Value: Perform standardized tests such as ASTM D790 to guide material selection for components like brackets, levers, or housings that must resist sagging or breaking under load, providing essential data for R&D and quality validation.

Shear & Peel Testing for Bonds and Layers

Quantify the strength of adhesives, bonds, and layered materials—a common requirement in assembly and packaging industries.

Typical Applications: Measuring the peel strength of tapes, labels, and flexible laminates, or the shear strength of adhesives bonding metals, plastics, or composites.

How It Works: Specialized peel fixtures (90°, 180°) or shear fixtures hold the sample. The test machine then pulls or slides the materials apart at a controlled speed and angle, precisely measuring the force required.

Standards & Value: Adhere to ASTM D903 (peel) or ASTM D1002 (shear) to ensure product reliability, optimize adhesive formulations, and guarantee that labels or seals perform as intended throughout their lifecycle.

Explore precision-engineered grips and fixtures designed specifically for your benchtop tensile tester. This modular system transforms your compact UTM into a versatile testing station, enabling accurate tensile, compression, peel, and bend tests on diverse materials—from polymers and thin metals to textiles and adhesives—all while ensuring full compliance with ASTM and ISO standards.

What is the typical price range for a benchtop tensile tester

The investment for a benchtop tensile tester varies based on force capacity, precision grade, software features, and included accessories. Generally, prices range from a few thousand to tens of thousands of USD. Standard models for basic QC offer excellent value, while high-precision or automated systems command a higher price. We provide transparent quotes tailored to your specific testing standards and requirements.

What is the maximum force a benchtop tester can handle, and what materials can it test?

Benchtop testers are designed for low to medium force applications, typically from 50N up to 20kN or 50kN for heavy-duty models. This makes them ideal for accurately testing polymers, plastics, textiles, elastomers, adhesives, thin metal foils, wires, and small components. For high-strength steels or large composites, a floor-standing UTM is recommended.

How accurate are benchtop tensile testers compared to larger machines?

High-quality benchtop tensile testers, like those from Derui, are engineered for laboratory-grade accuracy. They utilize precision load cells and robust frames to ensure data integrity and repeatability that meet or exceed international standards (ASTM, ISO). The key difference is not accuracy, but maximum force capacity and frame rigidity for larger samples.

Is it difficult to install and operate a benchtop tester? Do we need special training?

A major advantage of benchtop testers is their plug-and-play simplicity. They require minimal installation—just a standard power outlet and a level bench. Operation is streamlined through intuitive software. We include comprehensive initial training with every system, enabling most operators to perform standard tests proficiently after a short familiarization period.

Can a benchtop tensile tester also do compression, bend, and peel tests?

Absolutely. This is a core benefit. A benchtop universal testing machine (UTM) is a modular platform. By using dedicated fixtures (compression platens, bend fixtures, peel grips), the same machine can perform a wide range of tests—tensile, compression, flexure, shear, and peel—making it an incredibly versatile and cost-effective lab centerpiece.

How much bench space is required, and do we need any special lab preparation?

Benchtop testers are designed for space efficiency. A typical unit requires less than 1 square meter of bench space. No special lab preparation (like reinforced floors) is needed. Simply ensure the bench is sturdy, level, and can support the machine's weight (usually under 100kg).

What kind of after-sales support and calibration service is available?

We provide full lifecycle support: installation guidance, operator training, a comprehensive warranty, and access to technical support. We also offer certified calibration services to ensure your machine maintains traceable accuracy. Long-term spare parts availability is guaranteed to minimize future downtime.

Can the system be upgraded later with new grips or an extensometer?

Yes, modularity is a key feature. You can start with a core system and easily expand its capabilities later by adding specialized grips for different materials, high-precision extensometers for strain measurement, or even environmental chambers for temperature testing.

How do I choose between a single-column and a dual-column benchtop tester?

For most low-to-medium force applications on standard materials, a single-column benchtop tester is perfectly sufficient and more cost-effective. Choose a dual-column benchtop model if you require superior frame rigidity for slightly higher forces, slightly larger samples, or the utmost alignment precision for advanced research applications. Our engineers can help you decide.