A decisive testing strategy requires instrumentation that delivers uncompromising data integrity and operational certainty. Our dedicated solution portfolios are engineered to transform critical industry challenges—from material validation and package durability to specialized compliance testing—into reliable, standardized, and actionable results. Each portfolio integrates precision hardware, intuitive software, and deep application expertise to provide a cohesive foundation for quality assurance, risk mitigation, and informed decision-making across your product lifecycle.

Determine the fundamental mechanical properties of your materials with accuracy and repeatability. Our Universal Testing Machines (UTMs) form the core of any strength testing laboratory, performing precise tensile, compression, flexure, and shear tests on metals, polymers, composites, and more.

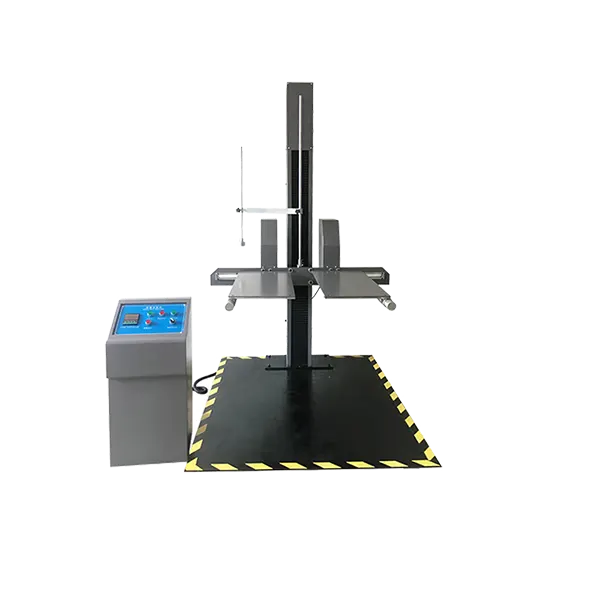

Ensure your packaging survives the distribution environment. Our systems simulate real-world hazards like drops, vibration, and compression to validate package performance and protect your products.

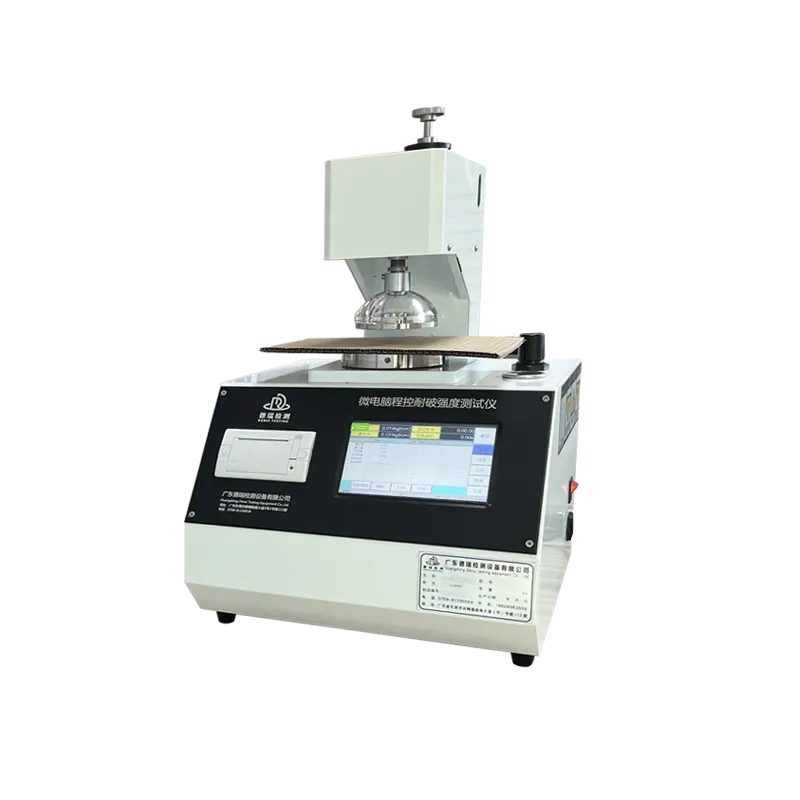

Go beyond universal testing with instruments fine-tuned for specific materials. Our dedicated testers deliver efficient, standardized analysis for paper, corrugated board, foams, elastomers, and plastics.

-

Engineering-Led Precision: As a direct manufacturer, our in-house team of over 20 engineers designs every system for uncompromising accuracy, durability, and modularity—from high-rigidity frames to traceably calibrated sensors. This ensures the data integrity that underpins your critical decisions.

-

Global Standards & Local Support: Our systems are pre-validated for key global standards (ASTM, ISO, ISTA, EN, GB/T), simplifying your compliance. Our global support network ensures you can implement and maintain these standards locally.

-

True Lifecycle Partnership: We provide more than equipment. From initial application consulting and custom configuration to installation, comprehensive training, and lifelong service support, we are your dedicated partner for the entire lifecycle of your lab.

-

Solutions, Not Just Products: Begin with a robust standard platform, then configure it with modular fixtures, software, and accessories to match your exact protocols. This future-proof approach allows your testing capability to evolve with your needs.

In today’s competitive and regulated industries, material failure or package damage is not an option. Testing Systems & Solutions are the critical backbone of risk mitigation, transforming uncertainty into validated performance data. They encompass the advanced equipment and rigorous methodologies used to evaluate everything from the tensile strength of an aerospace alloy to the drop resilience of an e-commerce package.

At Derui, we engineer more than just instruments; we provide integrated data integrity platforms. Our systems deliver the precise, reliable, and standards-compliant evidence you need to certify raw materials, validate components, simulate real-world hazards, and ensure end-product quality—empowering you to innovate with confidence, comply with global standards, and protect your brand reputation.

Choosing the right Universal Testing Machine (UTM) is a strategic investment that forms the cornerstone of your laboratory’s data credibility. Beyond basic specifications, a holistic evaluation ensures long-term integrity, operational excellence, and a strong return on investment for your entire material strength testing program.

Your UTM must be a universal platform, not a limited, single-function device. Core versatility is the ability to perform tensile (ASTM E8), compression (ASTM E9), flexure (ASTM D790), and shear tests with simple, quick-change fixtures. Look beyond today’s needs: a future-proof system offers a comprehensive ecosystem of accessories, allowing seamless future integration of video extensometers for non-contact strain, environmental chambers for temperature-dependent properties, or specialized fixtures for new materials and standards.

What are testing systems and solutions?

Testing Systems & Solutions refer to the integrated suite of precision equipment, software, and methodologies used to evaluate the properties and performance of materials, components, and finished products. This encompasses everything from universal testing machines for material strength to specialized systems for package durability and industry-specific compliance testing, ensuring quality, safety, and reliability from R&D to final production.

How do I choose between material strength testing, packaging testing, and specific material testers?

The choice depends on your primary goal. Choose Material Strength Testing (UTMs) if you need to understand fundamental mechanical properties (tensile, compression, etc.) of diverse materials. Opt for Packaging Validation to simulate transport hazards and ensure your packaging protects the product. Select Material-Specific Testers for high-throughput, routine quality control on a single material type like paper, foam, or plastic, where standardized, efficient testing is key.

Can one supplier provide all different types of testing equipment?

Yes, and there is a significant advantage in doing so. A single, experienced supplier like Derui can provide an integrated portfolio—from UTMs to drop testers and specialized analyzers. This ensures consistency in data quality, simplifies procurement and service, and offers a cohesive understanding of your broader testing challenges across the product lifecycle.

What industries commonly use these testing systems?

Virtually every manufacturing and R&D-driven industry utilizes them. Key sectors include: Aerospace & Automotive (for material and component validation), Packaging & Logistics (for distribution simulation), Medical Devices (for material biocompatibility and sterile packaging), Construction (for concrete and steel compliance), and Plastics & Consumer Goods (for quality control and innovation).

How important is software in modern testing systems?

Software is the central nervous system. It controls test parameters, ensures compliance with standards (ASTM, ISO, etc.), captures high-fidelity data, performs automatic analysis, and generates traceable reports. Advanced software transforms raw machine output into actionable, audit-ready insights, making it as critical as the hardware itself for data integrity and lab efficiency.

Can testing systems be automated or integrated into a production line?

Absolutely. Many systems, especially in packaging validation and material-specific testing, are designed for automation. Options include robotic arm integration for sample handling, conveyor belt systems, and programmable logic controller (PLC) interfaces. This enables 100% inline inspection, dramatically increases throughput, and eliminates operator variance for critical quality control points.

Frequently Asked Questions About Testing Systems & Solutions

The choice depends entirely on your primary testing focus. Universal Testing Machines (UTMs) are versatile core instruments for measuring fundamental mechanical properties (tensile, compression, flexure, shear) of materials like metals, plastics, and composites. Packaging Testers are specialized systems designed to simulate distribution hazards (drop, vibration, compression) to validate container performance and product protection. Material-Specific Testers (e.g., burst testers, impact testers) offer efficient, standardized analysis optimized for particular industries or materials, such as paper, corrugated board, or elastomers.

Can one supplier reliably provide all different types of testing equipment I need?

Yes, partnering with a single supplier like Derui that offers a comprehensive portfolio provides significant advantages. It ensures data comparability across different tests, simplifies procurement and vendor management, provides a unified software interface, and enables consolidated technical support. This holistic approach facilitates building a cohesive, future-ready laboratory, avoiding the compatibility and service challenges that can arise from managing multiple vendors.

What industries most commonly use these testing systems?

Our testing solutions serve a vast range of industries, including but not limited to: Aerospace & Defense (high-performance alloys), Automotive (component validation), Packaging (transport safety), Medical Devices (material biocompatibility), Electronics (connector durability, brittle component testing), Textiles & Nonwovens, Plastics & Composites, and Academic & Research Institutions.

What key global standards do your systems comply with?

Our systems are engineered and pre-validated to meet a comprehensive array of international and regional standards. This includes ASTM (American Society for Testing and Materials), ISO (International Organization for Standardization), EN (European Norms), ISTA (International Safe Transit Association for packaging), and GB/T (Chinese National Standards), among others. This ensures the test data you generate is recognized and respected in global markets.

How do you ensure the accuracy and longevity of your testing equipment?

Accuracy is rooted in our direct manufacturing approach: we design and control key components like the high-rigidity load frames, precision load cells, and control electronics in-house. Longevity is engineered through premium industrial-grade components and rigorous design based on deep application knowledge. We further support this with traceable calibration certificates and proactive service plans, ensuring your system delivers reliable performance throughout its entire service life.

What level of training and ongoing support can we expect after purchase?

We view training and support as fundamental to your success. Our standard offering includes comprehensive on-site installation and operational training for your team. Beyond this, we provide detailed user manuals, video tutorials, and a dedicated technical support portal. Our global network of engineers offers responsive remote assistance and prioritized on-site service, ensuring minimal downtime and continuous operational confidence throughout your system’s lifecycle.

What payment methods do you accept for testing solutions orders?

We accept major credit cards (Visa, MasterCard, American Express), bank/wire transfers, and payments via secure platforms like PayPal. Enterprise clients may also request invoice-based payments.