Every shipment faces risks—drops, vibration, compression, climate. A Packaging Validation Lab is your strategic solution, transforming these uncertainties into reliable data. By simulating real-world distribution hazards, you can scientifically prove that your packaging materials and designs will protect your product, preserving both your goods and your brand reputation.

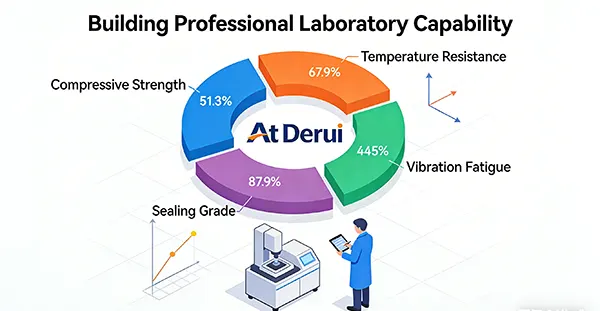

A comprehensive lab requires a suite of targeted instruments. Derui’s portfolio covers the complete spectrum of package performance testing.

At Derui, we provide the complete packaging test equipment and expertise to build your lab’s capability. We deliver the standards-compliant data you need to validate performance with confidence.

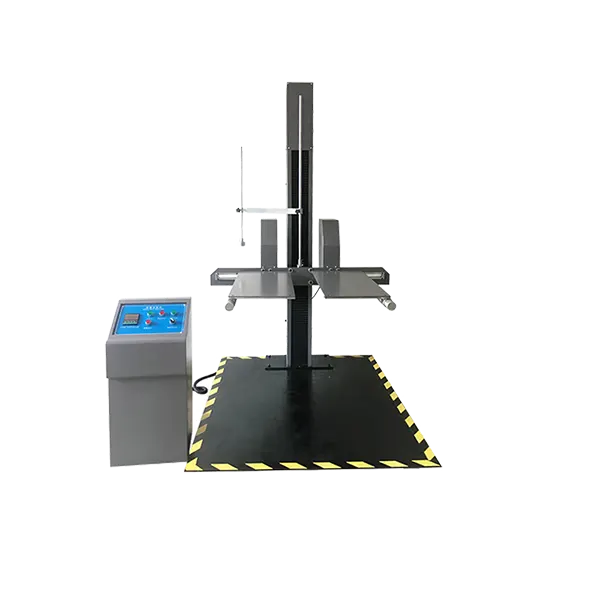

Precisely simulate the impacts encountered during manual handling and logistics transfers. Evaluate the resilience of your packaging materials and the cushioning performance of your design against specified drop heights and angles per ISTA, ASTM D5276.

Replicate the sustained stresses of transport by road, rail, sea, or air. Uncover weaknesses in seals, seams, and material fatigue using random or sinusoidal vibration profiles aligned with ISTA, ASTM D999 standards.

Determine the stacking strength of boxes, crates, and containers to prevent collapse in warehouses or during shipping. This critical packaging material testing ensures your design can withstand the required top-load force.

Subject packages and materials to controlled temperature and humidity extremes. Validate performance under frozen, tropical, or variable conditions, crucial for compliance with standards like ASTM D4332.

-

End-to-End Lab Partner: From defining your test plan to installing calibrated equipment and training your team, we support the full lifecycle of your validation lab.

-

Standards-Compliant by Design: Our systems are pre-configured for key ISTA Series, ASTM, and ISO standards, ensuring your tests are recognized and trusted globally.

-

Modular & Scalable Platform: Start with the essential packaging test equipment and expand your lab’s capabilities as your needs grow, all within a cohesive Derui ecosystem.

-

Data Integrity Focus: Robust frames, precise sensors, and reliable control software deliver repeatable, auditable data for critical pass/fail decisions and continuous improvement.

Industry Applications

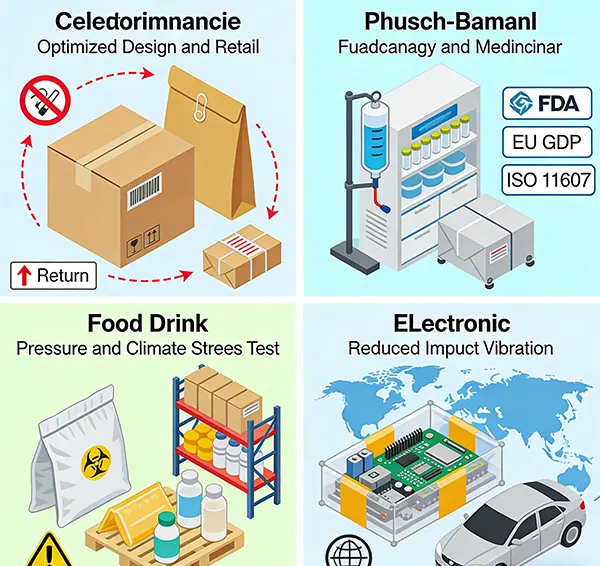

E-commerce & Retail: Minimize damage and returns in last-mile delivery. Optimize corrugated box strength (ECT) and cushioning design through drop and compression testing to reduce shipping costs and enhance customer loyalty.

Pharmaceutical & Medical Devices: Ensure product safety and regulatory compliance. Validate sterile barrier integrity and thermal performance of packaging by simulating transport vibrations and temperature extremes per FDA, EU GDP, and ISO 11607 standards.

Food & Beverage: Protect shelf-life and ensure safety. Test the seal strength of pouches and trays, and the stacking strength of containers under compression and climate stress to prevent leaks and preserve freshness throughout the cold chain.

Electronics & Automotive: Guard sensitive components against in-transit damage. Employ customized vibration and shock testing to validate protective packaging, ensuring components arrive functional and reducing production line failures.

A Packaging Validation Lab is a quality assurance facility equipped to scientifically simulate the hazards of the distribution environment—such as drops, vibration, compression, and climate extremes—on packaging materials and complete packages. The goal is to generate reliable, standards-compliant data that predicts real-world performance, mitigating the risk of product damage, ensuring regulatory compliance, and protecting brand reputation before shipment.

Test Standards & Regulatory Landscape: First, identify the mandatory and industry-standard protocols you must follow. This may include specific ISTA Series (e.g., 1A for basic integrity, 3E for e-commerce parcels, 6-FEDEX for Amazon) or ASTM methods (e.g., D4169 for general freight, D7386 for warehouse handling). Consider if you need to test for international regulations like ISO 2247 (vibration) or retailer-specific requirements. Your equipment must be capable of executing these standards with compliant methodology and reporting.

What payment methods do you accept for testing solutions orders?

We accept major credit cards (Visa, MasterCard, American Express), bank/wire transfers, and payments via secure platforms like PayPal. Enterprise clients may also request invoice-based payments.

What Should I Look for When Choosing a Packaging Validation Lab?

When selecting a Packaging Validation Lab, consider their accreditation, expertise, and the range of tests they offer. Evaluate their experience with your specific product type and industry norms. Additionally, look for labs equipped with modern technological resources and those that provide clear timelines and communication throughout the validation process.

How Long Does the Packaging Validation Process Take?

The duration of the packaging validation process varies depending on the complexity of the tests and the type of packaging being assessed. It can range from several days to weeks. Factors influencing this timeline include the number of tests required, the materials being used, and any specific industry standards that must be met.

Who Should Use Packaging Validation Services?

Businesses involved in manufacturing and distributing products—from food and pharmaceuticals to electronics—can benefit from packaging validation services. Companies looking to enhance product safety, reduce returns due to packaging failures, and ensure compliance with regulations should consider working with a Packaging Validation Lab.

What Types of Tests Are Conducted in Packaging Validation Labs?

In Packaging Validation Labs, various tests are performed, such as mechanical tests (burst, compression, and drop tests), environmental tests (humidity, temperature, and light exposure), and transportation tests to simulate real-world shipping conditions. Additionally, labs may conduct microbiological tests for food packaging or compatibility tests for pharmaceuticals to ensure safety and efficacy.

Why is Packaging Validation Important?

Packaging validation is crucial to ensure that products are safeguarded throughout their lifecycle. It helps identify potential weaknesses in packaging that could lead to product spoilage or damage. Validation ensures that packaging materials can withstand physical, environmental, and chemical stresses, thereby maintaining product quality and safety, while also complying with industry regulations.

How do I validate a new packaging material?

Start with material-level tests (like compression or puncture resistance), then progress to prototype testing in a simulated distribution environment (drop, vibration) using the relevant ISTA or ASTM standard to validate the full system.

Can one machine perform both drop and vibration tests?

Typically, no. Drop testers and vibration testers are specialized pieces of packaging test equipment designed for fundamentally different mechanics. A complete packaging validation lab will include both.

What's the difference between ISTA 3A and ASTM D4169?

While both are core to packaging validation, they serve different purposes. ISTA 3A is a prescribed performance test procedure that simulates a specific parcel delivery environment. It provides a fixed sequence of tests (e.g., vibration, shock, compression) with defined parameters that your package must pass. ASTM D4169, on the other hand, is a practice for performance testing that offers a “toolbox” of test methods and allows you to assemble a custom test plan based on your unique distribution cycle (DC) hazards. Think of it this way: ISTA 3A is a fixed menu, while ASTM D4169 is a build-your-own menu guided by your DC profile. Many labs use both—ISTA for standard compliance and ASTM for tailored, risk-based validation.

How often should packaging test equipment be calibrated?

For reliable, audit-ready data, a rigorous calibration schedule is essential. We recommend:

-

Annual Calibration: A full, traceable calibration by an accredited lab for all critical sensors (load cells, accelerometers, displacement transducers) to ensure absolute accuracy against national standards.

-

Regular Verification: Frequent “in-house” checks (e.g., monthly or quarterly) using certified reference weights or calibration fixtures to confirm system stability and repeatability between annual calibrations.

-

Event-Based Recalibration: Immediate recalibration after any event that could affect measurement integrity, such as equipment relocation, physical shock, or a major repair.

Derui offers comprehensive calibration services and support plans to help you maintain this schedule, ensuring your lab’s data is always defensible.

Can you help us design a test plan for a specific retail compliance standard?

Absolutely. This is a core part of our partnership. Our application engineers routinely assist clients in developing test plans for standards like Amazon’s FRUSTA-Free, Target’s T3000, or Walmart’s packaging requirements. The process involves: 1) Analyzing your specific supply chain and the retailer’s protocol, 2) Mapping the required tests to our equipment capabilities (e.g., defining correct drop sequences, vibration profiles, compression forces), and 3) Configuring the software and fixtures to execute the plan accurately. We ensure your lab is not just equipped, but optimally set up to achieve and document compliance efficiently.