Explore our precision-engineered vibration test equipment, designed to validate product durability and reliability under simulated dynamic stress. From compact electrodynamic shakers for PCBs to high-force servo-hydraulic systems for automotive components, our solutions deliver uncompromising accuracy for compliance with global standards like ISO, ASTM, and MIL-STD—all backed by comprehensive technical support.

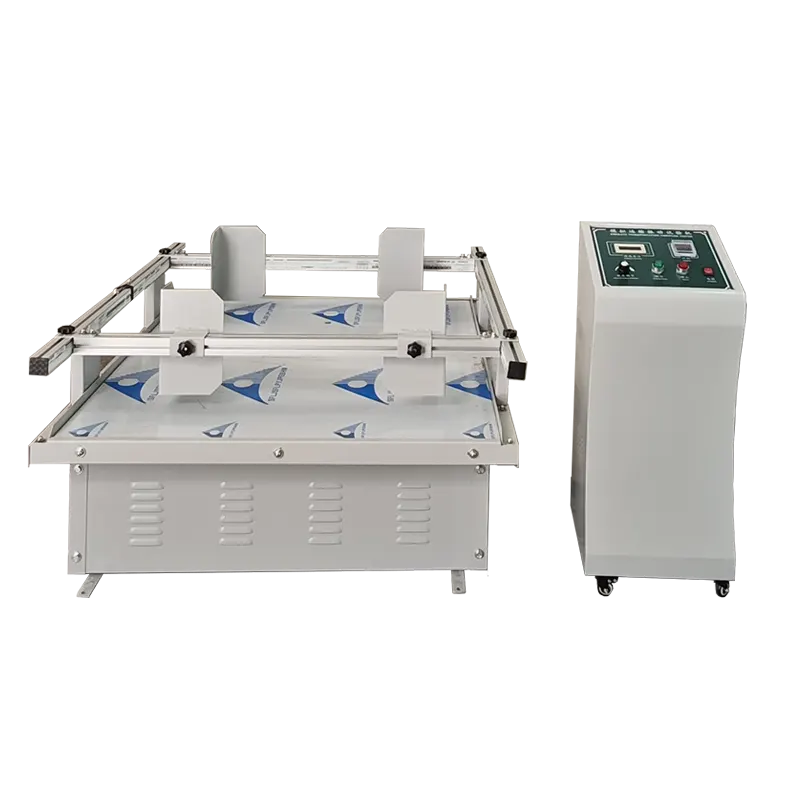

Simulates: Transportation stress, mechanical wear, structural resonance, and operational fatigue in products and components.

Engineered for Precision & Reproducibility: Our systems feature advanced digital controllers and high-fidelity amplifiers to ensure exact replication of sine, random, and shock profiles. This guarantees repeatable, audit-ready test results that meet stringent international standards.

Configurable for Your Exact Test Profile: Go beyond basic vibration. Our platforms support customized test regimes—from sine sweeps for resonance detection to complex random vibration spectra and classical shock pulses—tailored for your specific industry and failure mode analysis.

Built for Demanding Duty Cycles: Constructed with robust armatures, high-quality bearings, and efficient cooling systems, our shakers are engineered for continuous operation in R&D and production QC environments, ensuring longevity and minimal downtime.

Integrated Data Acquisition & Analysis: Transform vibration events into engineering insights. Optional integrated solutions allow real-time monitoring of control and response parameters, enabling precise fatigue analysis, transmissibility studies, and design validation.

Selecting the optimal system is critical for accurate reliability testing. Use this guide to match your requirements with the right technology.

-

Key Standards: Identify required protocols (e.g., IEC 60068, MIL-STD-810G, ISO 16750, ASTM D999). These dictate test types (sine/random/shock), frequency ranges, and acceleration levels.

-

Specimen Dynamics: Determine the maximum weight, size, and center of gravity of your test unit (DUT). This is the primary driver for selecting system force (lbf/kN) and table size.

A Vibration Test System (or shaker system) is an integrated instrument designed to simulate and apply controlled mechanical vibration stimuli to a product or component. Its purpose is to identify structural weaknesses, validate design durability, and ensure operational reliability by exposing the test unit to the dynamic stresses it will encounter throughout its lifecycle—from transportation and handling to actual use.

This proactive validation is fundamental to reliability engineering, allowing developers to discover failure points like solder cracks, resonant frequencies, and material fatigue in a controlled lab environment long before field failures occur.

The system operates on a closed-loop control principle to accurately replicate specified vibration profiles:

Profile Definition: The engineer defines the test profile (e.g., a 1.5 Grms random vibration spectrum from 10-1000 Hz) in the system's digital controller software.

Fixture & Specimen Mounting: The Device Under Test (DUT) is securely fastened to the shaker's table (armature) using a dedicated fixture. A control accelerometer is attached to the fixture or DUT.

Closed-Loop Execution: The controller sends a drive signal to the high-power amplifier. The amplifier powers the shaker (electrodynamic or hydraulic), causing the table to move. The control accelerometer feeds back the actual motion to the controller, which continuously adjusts the drive signal in real-time to match the desired profile precisely.

Monitoring & Data Acquisition: Response accelerometers on the DUT measure its reaction to the vibration. The system monitors for deviations, aborts if safety limits are exceeded, and records all data.

Post-Test Analysis: The recorded response data is analyzed to identify resonant frequencies, evaluate transmissibility, and assess any performance degradation or physical damage to the DUT.

More Than a Shaker: Your Complete Dynamic Validation Hub

Resonance Search & Fatigue Testing: Identify natural frequencies and perform sine dwell tests to accelerate fatigue failures, critical for aerospace components and automotive electronics.

Transport Simulation: Replicate the random vibration environment of land, sea, and air transport to validate packaging and product robustness for logistics (ISTA, ASTM D4169).

Product Lifecycle Validation: Simulate years of operational wear and tear in hours through accelerated random vibration tests, essential for consumer electronics and automotive modules.

Combined Environmental Stress Testing (CEST): Integrate the shaker with thermal chambers for simultaneous vibration and temperature cycling, uncovering failures only seen under combined stresses.

Still unsure which system is right for your validation challenges? Our engineering team specializes in translating product requirements into precise test specifications.

How do I calculate the required force (thrust) for my application?

The fundamental formula is Force (N) = [Mass of DUT + Mass of Fixture] x Acceleration (m/s²). Always include fixture mass and account for peak acceleration in your profile. Our application

Can one system perform sine, random, and shock testing?

Yes, a modern digital vibration controller allows a single electrodynamic shaker system to generate precise sine, random, and classical shock waveforms. The system must have sufficient displacement and frequency range to cover all your target profiles.

Why is fixture design so important?

A poorly designed fixture can dampen vibration, create unintended resonances, or even fail catastrophically. It must rigidly couple the DUT to the shaker table while being as lightweight as possible to maximize usable force. We offer expert fixture design consultation.

What kind of maintenance do these systems require?

Regular maintenance includes checking armature air gaps, cleaning/replacing cooling filters, verifying torque on mounting hardware, and annual calibration of the shaker, amplifier, and control sensors to ensure ongoing accuracy.

Do you provide installation, training, and IQ/OQ services?

Yes. We offer turnkey solutions including professional installation, comprehensive operator training, and full documentation packages (Installation/Operational Qualification) to support your quality system and regulatory audits.

We need to upgrade from single-axis to multi-axis testing. Is this possible?

Many of our systems are designed with scalability in mind. It is often possible to upgrade a single-axis vertical shaker to a multi-degree-of-freedom (MDOF) system by adding horizontal slip tables and additional controllers. Consult with us about your future roadmap.

What are the benefits of using Vibration Test Systems?

Using Vibration Test Systems has numerous benefits, including identifying potential product failures before they occur, ensuring compliance with industry standards, enhancing product reliability, and minimizing costly recalls. They can also help in refining product designs and improving customer satisfaction by delivering robust, quality products that withstand expected operational conditions.

What industries utilize Vibration Test Systems?

Vibration Test Systems are utilized across a variety of industries, including aerospace, automotive, electronics, telecommunications, and medical devices. Each industry has specific testing requirements related to the types of vibrations encountered during use, making vibration testing crucial for product development and quality assurance.

How often should Vibration Testing be performed?

The frequency of Vibration Testing depends on various factors, including the specific industry standards, the critical nature of the product, and any design changes. Generally, it is advisable to perform vibration tests during the development phase, after significant modifications, and periodically for maintenance to ensure ongoing product reliability.

How do I accurately calculate the required force (thrust) rating for my shaker system?

The basic formula is Force (lbf or N) = Total Moving Mass x Peak Acceleration. The “Total Moving Mass” must include your heaviest Device Under Test (DUT), its fixture, and the shaker armature/head expander. For random vibration, you must calculate using the peak acceleration in the profile, not just the GRMS value. We strongly recommend a safety margin of 30-50% over your calculated peak force to ensure headroom and system longevity. Our engineering team provides free thrust calculations as part of the consultation.

Do your systems support Combined Environmental Stress Testing (CEST)?

Absolutely. Our shakers are engineered for seamless integration with thermal chambers (both mechanical convection and liquid-to-liquid) to perform simultaneous vibration and temperature cycling. This CEST capability is crucial for uncovering failures that only occur under combined stresses, which is a requirement in many advanced automotive, aerospace, and defense validation programs.