Explore our curated selection of precision drop test equipment. Each model, from space-saving tabletop units to robust floor-standing systems, is engineered for reliability, repeatability, and compliance with global standards—all supported by our worldwide service network.

Simulates: The handling drops and impacts of parcel shipping and handling.

Engineered for Uncompromising Repeatability: Our patented release mechanisms ensure a true "zero-initial-velocity" free fall on every test, eliminating result variation caused by pushing or tipping for reliable, audit-ready data.

Configurable for Your Exact Standard: Go beyond basic height adjustment. Our systems are pre-configured with test profiles for major ISTA, ASTM, and MIL-STD procedures, with fixtures designed for precise edge, corner, and flat-surface impacts.

Built for Durability & Safety: The robust impact base and rigid frame absorb extreme forces test after test, while integrated safety interlocks and protective enclosures ensure complete operator protection.

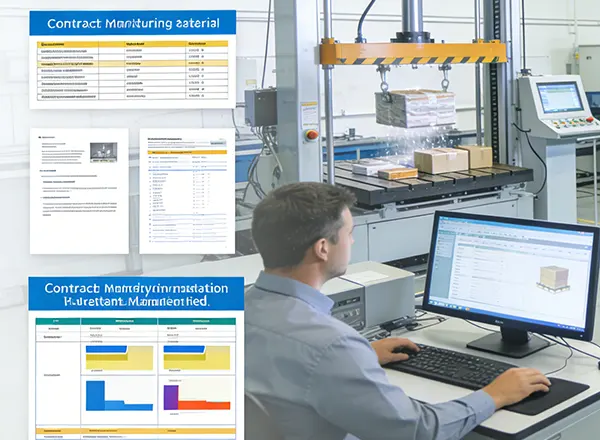

Smarter Data from Every Impact: Optional integrated data acquisition turns impact events into actionable insights. Measure peak G-forces, velocity change, and pulse waveforms to feed your simulation models and failure analysis.

Selecting the ideal drop tester is crucial for obtaining reliable, standard-compliant results and ensuring a strong return on investment. Use this focused guide to evaluate your needs against the key specifications.

Primary Standards: Identify the mandatory test methods (e.g., ISTA Series, ASTM D5276, MIL-STD-810G). This dictates required drop heights, impact surfaces (faces, edges, corners), and release mechanisms.

Sample Weight & Size: Determine the maximum weight and outer dimensions of your test specimens. Choose a tester with a payload capacity and platform size that comfortably accommodates your largest product with room for fixtures.

A drop tester is a calibrated instrument designed to scientifically simulate and quantify the effects of free-fall impacts on a product or its packaging. By repeatedly and precisely dropping a sample from specified heights and orientations onto a standardized surface, it provides objective data on product ruggedness, structural integrity, and packaging system performance.

This controlled testing is fundamental to "design for reliability," allowing engineers to identify failure points, validate protective solutions, and ensure products withstand the hazards of real-world logistics and handling before they reach the customer.

The principle is straightforward; the execution is precise. A drop tester operates through a defined sequence:

-

Parameter Setup: The operator selects the test protocol (e.g., ISTA 3A) via the intuitive controller, defining drop height, impact surface, and sequence of faces, edges, and corners.

-

Sample Positioning: The test specimen is secured to the release platform or in a dedicated fixture, ensuring the required impact face, edge, or corner is perfectly oriented for the drop.

-

Controlled Release: Upon initiation, the system's release mechanism (electromagnetic or pneumatic) disengages instantaneously and cleanly, allowing the sample to fall purely under gravity without induced spin or push-off.

-

Impact & Measurement: The sample strikes the hardened impact plate. In advanced systems, an onboard accelerometer simultaneously captures the shock pulse data.

-

Post-Test Evaluation: The sample is inspected for damage, and functional checks are performed. The machine records the drop parameters, and if equipped, the associated shock data for comprehensive reporting.

While package validation is a core function, modern drop testers are central to broader durability engineering.

Product Ruggedness Validation: Test finished goods like smartphones, tablets, or IoT devices against internal durability specs or standards like Telcordia GR-63.

Component-Level Stress Screening: Evaluate the solder joint strength, housing integrity, or display resilience of sub-assemblies and critical internal components.

Comparative Cushioning Analysis: Objectively compare the performance of different foam, molded pulp, or air-cellular materials by measuring G-forces transmitted to a calibrated payload.

Design Verification & FMEA: Generate quantitative shock data to validate computer simulations (FEA) and support Failure Mode and Effects Analysis during product development.

What is the key difference between a "free-fall" and a "shock" (or "zero-drop") tester?

A free-fall tester drops the sample itself from a height. A shock tester lifts and drops the impact base while the sample is stationary on top, simulating an impact to the underside of a large, non-droppable product. The choice depends on your test standard and product type.

Our products vary widely in size and weight. How do we select the right capacity?

Choose a model where your heaviest, largest sample is within 60-75% of the tester's maximum rated weight and platform size. This ensures longevity of the machine and accurate, consistent results. Our team can help you analyze your product mix.

How critical is the release mechanism to test accuracy?

It is the most critical component. A poor release can impart spin or lateral motion, drastically altering the impact angle and energy. Our electromagnetic and pneumatic releases are engineered for clean, consistent disengagement, which is essential for repeatable, standard-compliant testing.

Can your software help us manage compliance documentation?

Yes. Our optional ProDrop Software Suite not only controls the tester but also stores standard test methods, records all test parameters and results, and generates formatted PDF reports with pass/fail summaries—streamlining audit preparation and quality documentation.

What does routine maintenance involve?

Maintenance is minimal but crucial. It primarily involves regular inspection and cleaning of the release mechanism, verification of drop height calibration, and checking the condition of the impact surface. We provide clear schedules and support for these activities.

Do you offer validation (IQ/OQ) or on-site calibration services?

We offer comprehensive service packages, including Installation/Operational Qualification (IQ/OQ) documentation and on-site calibration performed by certified technicians with traceable measurement standards to ensure your system remains audit-ready.

We are new to standardized drop testing. Can you provide guidance?

Absolutely. Our applications engineers are experts in transit testing standards. We can provide guidance on selecting the appropriate test sequence for your distribution channel, help define a test plan, and even offer sample testing services to get you started.

Can drop testers be used for all types of products?

What are the key features of a drop tester?

Key features of a drop tester may include adjustable drop heights, various impact surfaces, data logging capabilities, and high-speed cameras for detailed analysis. Advanced models may offer automated testing cycles and software integration for easier data analysis and reporting, making them invaluable in product testing for quality assurance.

What industries benefit from using drop testers?

Several industries benefit from the use of drop testers, including consumer electronics, automotive, packaging, and aerospace. These sectors rely on drop testing to ensure their products can withstand impact forces during transport and use. By identifying vulnerabilities through testing, companies can enhance product durability and reduce return rates, leading to improved customer satisfaction.

How can I choose the right drop tester for my needs?

When selecting a drop tester, consider factors such as the types of products you are testing, the required drop heights, and the features you need (like data logging or automation). It's also beneficial to look for testers that comply with industry standards relevant to your products. Consulting with manufacturers and reading user reviews can provide valuable insights to make an informed choice.