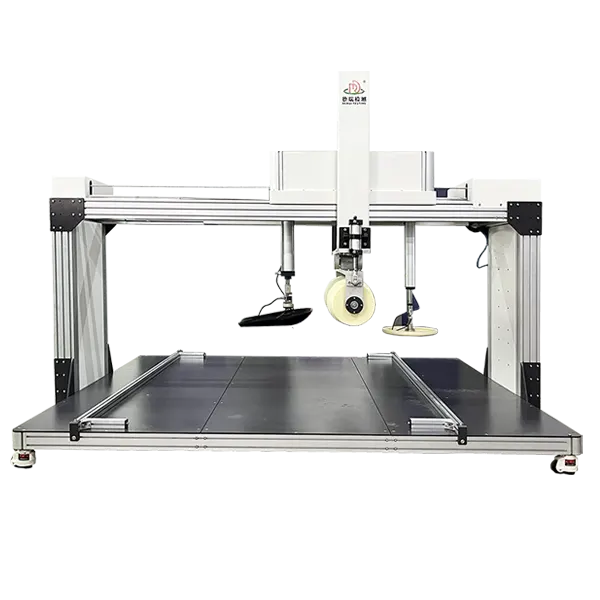

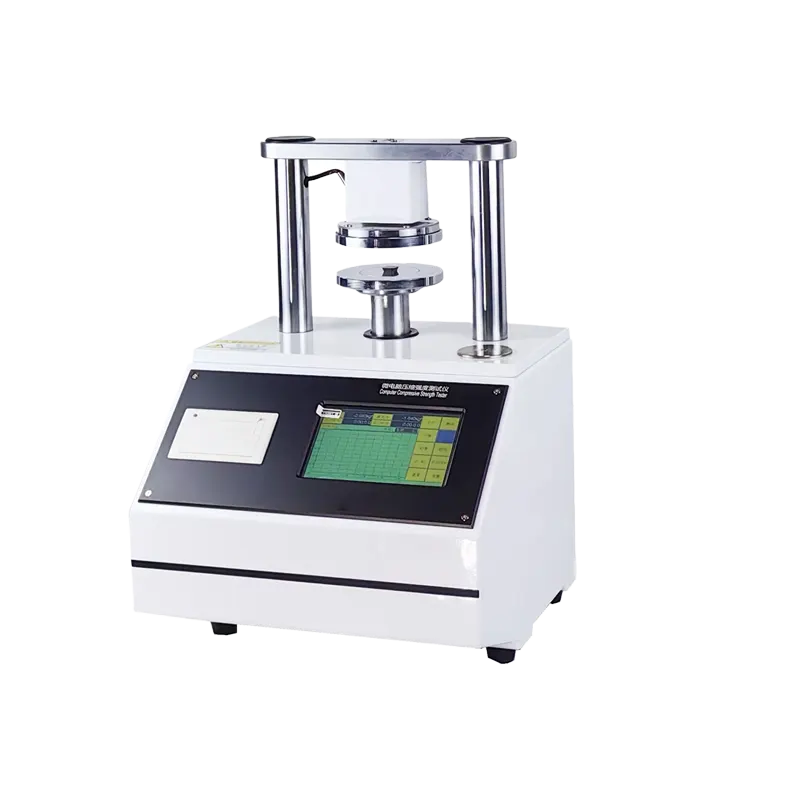

This machine is used for determining the indentation hardness of porous elastic materials. It can perform standardized tests specified by national standards on polyurethane sponge foam samples, accurately measuring the indentation hardness of sponges, foams, and similar materials. Additionally, it is suitable for measuring the specified indentation hardness of manufactured seat foam components (such as backrest foam, seat cushion foam, etc.), precisely determining the indentation hardness of various foam parts in seats.

Principle:The sponge foam compression stress test places the sample between upper and lower compression plates. The upper plate moves downward at a specified speed to compress a sample of defined dimensions to the indentation depth required by national standards for Method A (B or C). The load cell integrated into the upper plate senses the pressure and transmits this feedback to the controller, which processes and displays the reading. This enables the accurate measurement of indentation hardness for sponge, foam, and other similar test materials.

Functional Features

- Auto Zero: The system automatically resets to zero upon receiving the test start command from the computer.

- Auto Return: Automatically returns to the initial position after the specimen breaks.

- Auto Range Switching: Automatically switches between different force ranges based on the load magnitude to ensure measurement accuracy.

- Speed Adjustment: The test speed can be freely adjusted for different specimens.

- Calibration Verification: The system allows for accurate calibration verification of force values.

- Control Modes: Enables selection of test methods based on requirements: Test Force, Test Speed, Displacement, or Strain.

- Multi-Functional: Equipped with sensors of different specifications, enabling a wide range of applications.

- Curve Traversal: After test completion, users can use the mouse to examine any point on the test curve to view its corresponding force and deformation data for analysis.

- Real-time Display: Dynamically displays test data and curves during the testing process.

- Result Handling: Test results can be saved and retrieved; data curves can be analyzed.

- Limit Protection: Features both programmable (software) and mechanical limit protection.

- Overload Protection: Automatically shuts down when the load exceeds the rated value.

Core Structural Components

The core structural components of the sponge compression fatigue testing machine include the following key modules, each responsible for specific functions in the testing process:

- Loading System

- Compression Mechanism: Driven by a servo motor, pneumatic cylinder, or hydraulic cylinder, this mechanism works in conjunction with precision ball screws or linkage systems to apply vertical compression to the sponge sample. It enables precise control over compression force (e.g., 0.1N~5000N) or compression displacement (e.g., 1mm~100mm).

- Pressure Sensor: Monitors the applied force in real time during compression to ensure loading accuracy (error typically ≤±1%).

- Sample Fixing Device

- Comprises upper and lower pressing plates (typically made of stainless steel or polyurethane with smooth, flat surfaces) to secure the sponge sample and prevent lateral displacement. Some devices support adjustable plate spacing to accommodate samples of varying thicknesses (e.g., 10mm~200mm).

- Control System

- Centered around a PLC (Programmable Logic Controller) or industrial computer, this system automates the testing process by controlling parameters such as loading frequency (e.g., 0.5Hz~5Hz), compression stroke, cycle count (e.g., 1000~100,000 cycles), and other variables via pre-programmed routines.

- Data Acquisition and Analysis Module

- Equipped with displacement sensors, force sensors, and optional temperature/humidity sensors (in high-end models), this module records real-time force-displacement curves, thickness variation rates, and other data during testing. The integrated software generates reports (e.g., fatigue life curves, rebound rate decay trends).

- Auxiliary Systems

- Includes safety features (e.g., emergency stop button, light curtain protection), sample cutting tools (e.g., standard annular cutter), and an optional environmental temperature/humidity control chamber to simulate different usage conditions.

enforce standards

1.GB/T 18941 ISO 3385 "Soft foam polymers - Determination of fatigue by constant load impact Method"

2.QB/T QBT 2819-2006 "Determination of Long-term Fatigue Properties of Soft Foam Materials"

3.QCT56-93 "Test Methods for Performance of Automotive Seat Lining Materials

Functional features

- Automatic zeroing: After receiving the command to start the test, the system automatically zeros.

- Automatic return: After the sample breaks or is damaged, it automatically returns to the initial position.

- Adjust the speed: The test speed can be adjusted arbitrarily according to different samples.

- Indication verification: The system can accurately calibrate the force value.

- Control method: According to the test requirements, test methods such as test force, test speed, and displacement can be selected.

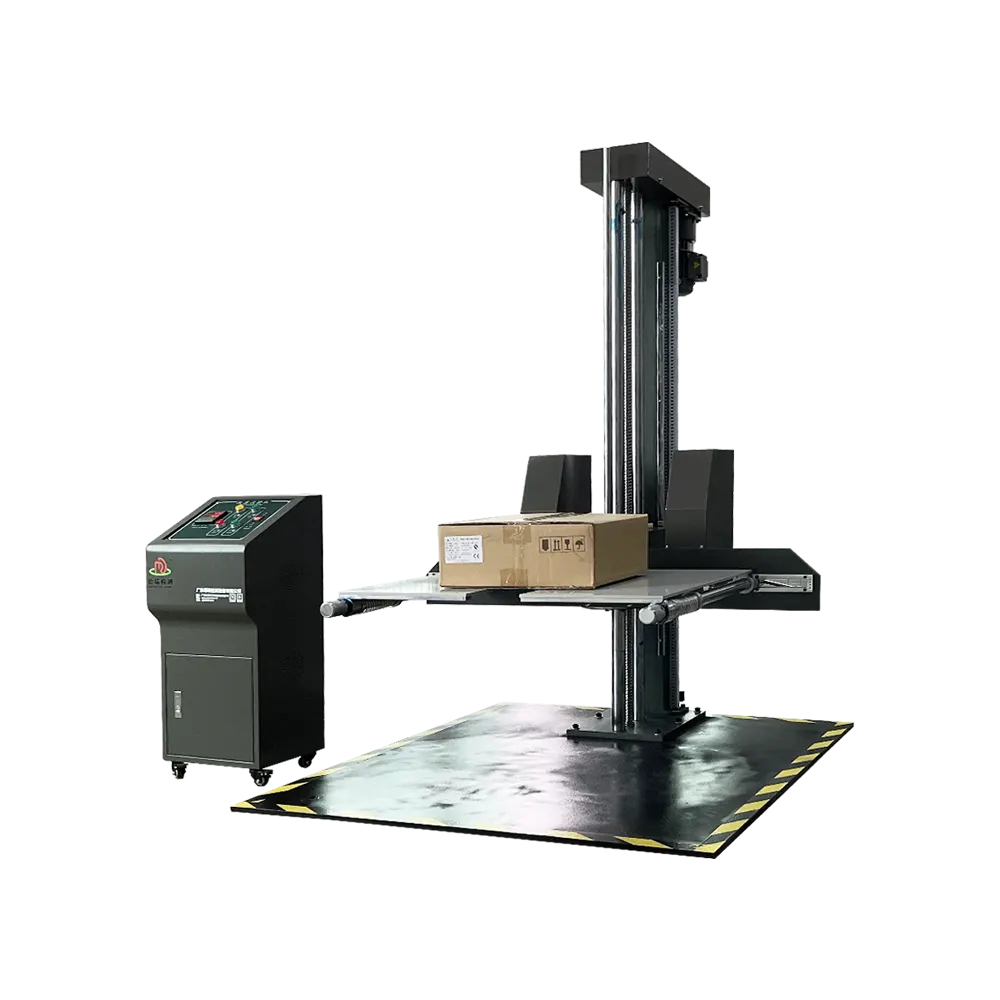

5. Application Scenarios

The sponge compression fatigue testing machine is widely used across industries to assess the durability and fatigue resistance of sponge materials, ensuring product quality and performance under repeated stress conditions. Key application areas include:

- Furniture Industry:

- Testing the durability of sofa and mattress sponges to ensure they resist compression deformation (e.g., sagging) and maintain resilience after prolonged use, meeting comfort and structural integrity standards.

- Automotive Manufacturing:

- Evaluating the fatigue life of seat and headrest sponges in vehicles to ensure they withstand repeated compression from occupants, meeting safety, comfort, and longevity requirements.

- Packaging Materials:

- Assessing the compressive resistance and recovery performance of cushioning sponges used in logistics and shipping, ensuring protection for packaged goods against repeated impacts or squeezing during transit.

- Footwear Industry:

- Testing the resilience and durability of sponge materials used in shoe insoles and midsoles, ensuring long-term comfort and performance under repeated stress from foot movement.

- Other Applications:

- Sports Equipment: Evaluating sponge components in mats, pads, or protective gear for durability under repeated use.

- Medical Devices: Testing sponge materials in cushions or supports for long-term resilience in healthcare applications.