An office chair leg fatigue and compression resistance tester is a specialized testing device used to simulate the repeated pressure or impact endured by office chair legs (such as star bases, caster bases, etc.) during actual use, primarily assessing the durability, fatigue resistance, and long-term safety of the chair leg structure to ensure compliance with relevant quality standards (e.g., GB/T 10357, BIFMA X5.1). Below is a detailed introduction to this equipment:

I. Core Functions and Testing Objectives

- 1.Primary Functions

- •Simulate the cyclical vertical pressure (e.g., repeated loading from human body weight) experienced by office chair legs during long-term sitting, movement, or load-bearing;

- •Test the structural stability of chair legs (single leg or entire base) under continuous loading, detecting potential failures such as fractures, deformations, loosening, or abnormal noises;

- •Evaluate the reliability of materials (e.g., metal, plastic, nylon) and manufacturing processes (e.g., welding, injection molding) by setting different pressure values, frequencies, and cycle counts.

- 2.Testing Objectives

- •Verify whether the chair legs meet industry standards (e.g., load capacity ≥113kg/person, cycle count ≥100,000 times without failure);

- •Identify design flaws (e.g., stress concentration points, weak joints in connections);

- •Provide data support for product R&D, quality control, and factory inspections.

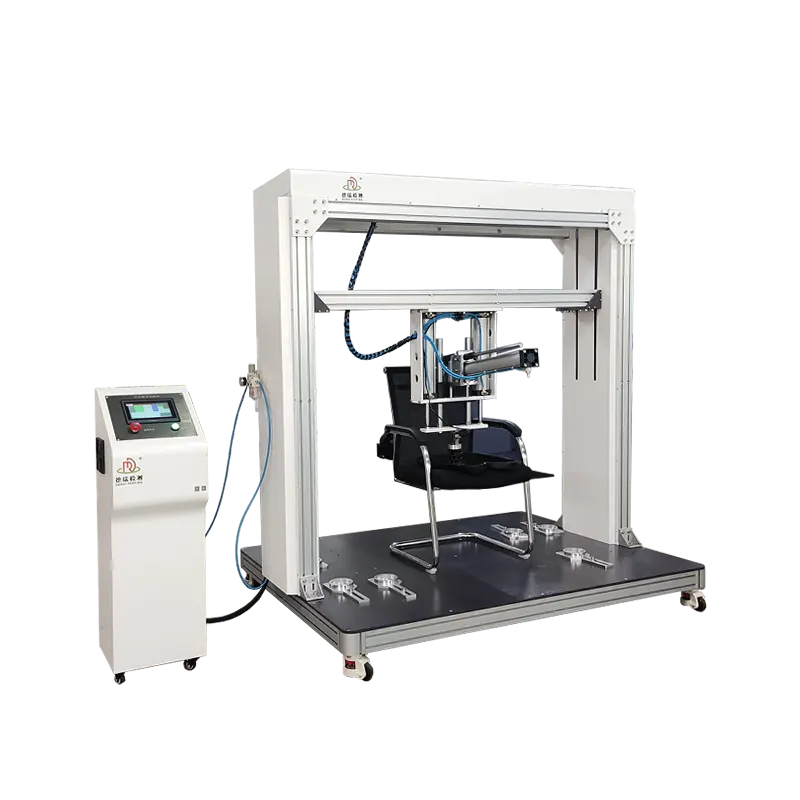

II. Key Components

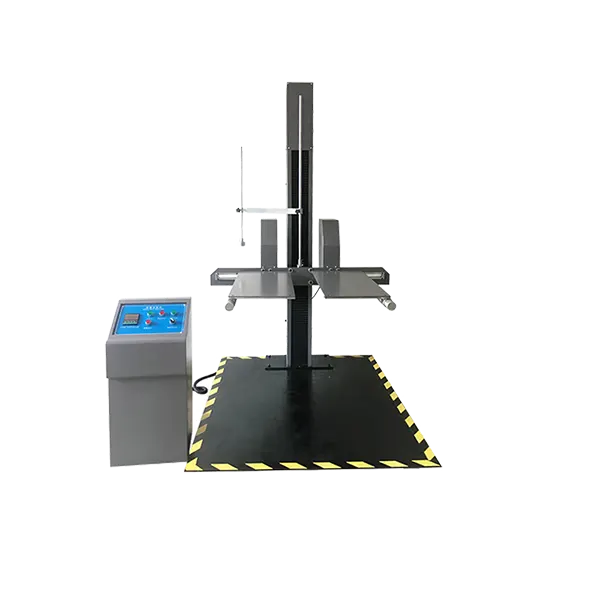

- 1.Loading System

- •Pressure Application Device: Typically driven by an electric cylinder, hydraulic cylinder, or servo motor, the loading head applies precise vertical pressure (common range: 0–500kgf or higher, adjustable based on leg type);

- •Sensors: High-precision force sensors monitor the actual pressure applied in real time during the test, feeding back to the control system to ensure accuracy (error ≤±1%).

- 2.Motion Control Mechanism

- •Lifting/Reciprocating Module: Drives the loading head to perform up-and-down reciprocating motion at a set frequency (e.g., 1–3Hz, i.e., 60–180 cycles per minute), simulating the cyclical pressure of human sitting;

- •Servo Motor/Stepper Motor: Paired with ball screws or linear guides to ensure smooth motion and precise positioning, avoiding off-center loading that could skew test results.

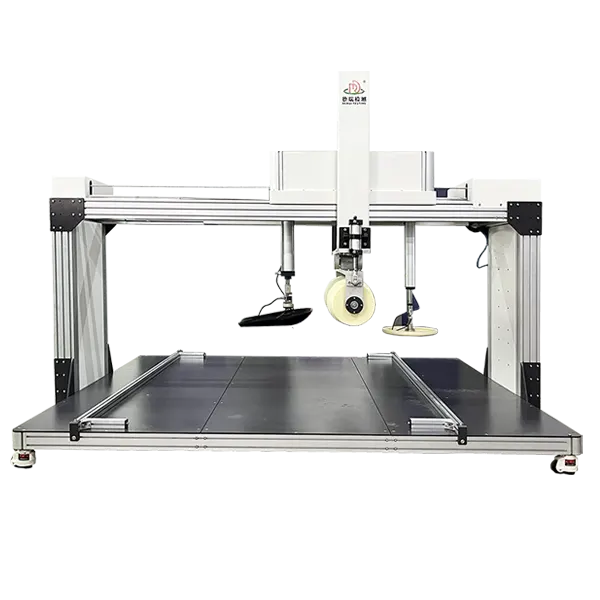

- 3.Fixation and Support Devices

- •Chair Leg Fixation Platform: Adjustable clamps or bases compatible with various office chair leg specifications (e.g., star bases with diameters Φ50–100mm, caster bases), ensuring stable fixation during testing (no wobbling);

- •Simulated Ground/Surface: Some devices include a rigid platform (e.g., steel plate) to mimic real-world ground contact conditions.

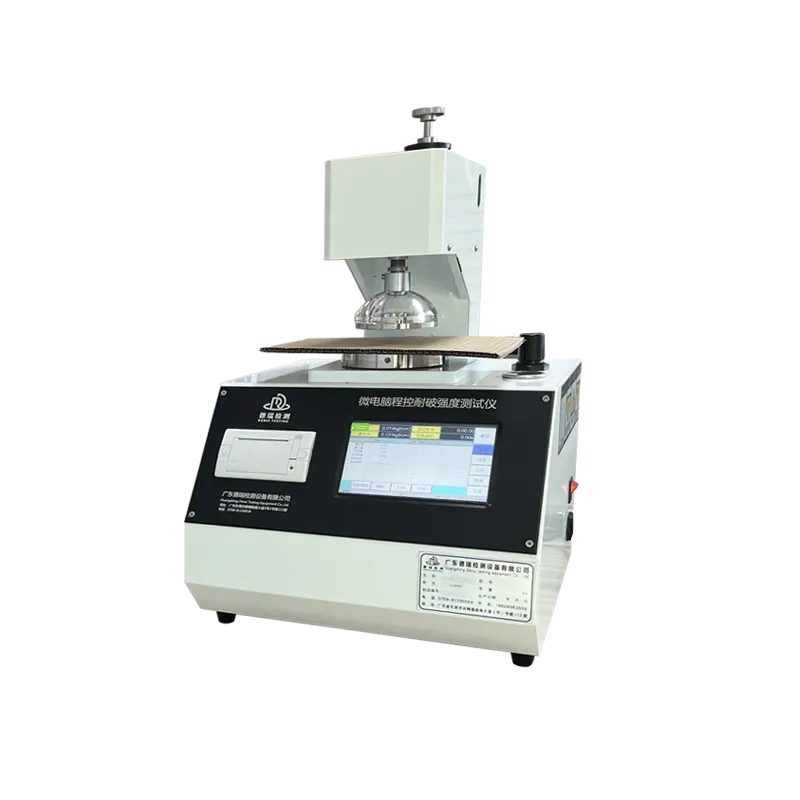

- 4.Control System and Data Acquisition

- •Control Panel: Supports manual/automatic modes, allowing users to set parameters such as pressure value, loading frequency, and cycle count (e.g., 10,000, 50,000, or 100,000 cycles);

- •Display Screen: Shows real-time data including current pressure, cycle count, and running time;

- •Data Storage and Export: Records pressure curves, peak/valley values, and failure points (e.g., cracks appearing after a specific cycle) during testing, with support for USB or computer-based analysis.

III. Testing Procedure Example

- 1.Sample Preparation: Secure the office chair leg (or the detached base of a disassembled chair) on the test stand, ensuring the loading direction aligns with actual use (typically vertical downward).

- 2.Parameter Setup: Configure the loading force (e.g., 150kg to simulate adult sitting pressure), frequency (e.g., 2Hz), and target cycle count (e.g., 100,000 times) based on standards or client requirements.

- 3.Start Testing: The device automatically applies cyclical pressure according to the programmed settings, with the loading head repeatedly pressing down → rebounding to simulate continuous sitting.

- 4.Real-Time Monitoring: Observe whether the chair leg exhibits deformations (e.g., bending, dents), abnormal noises (e.g., metal friction), or structural damage (e.g., weld cracks, plastic part fractures).

- 5.Result Evaluation: After testing, inspect the leg’s integrity—if it fails (e.g., fractures) before reaching the target cycle count, it is deemed non-compliant; if it completes all cycles without significant damage, it meets durability requirements.

IV. Applicable Standards and Use Cases

- •Common Standards:

- •Domestic: GB/T 10357.3-2013 Furniture Mechanical Performance Tests – Part 3: Stability of Chairs and Stools, GB/T 28008-2020 Furniture – Strength and Durability Test Methods for Seats;

- •International: BIFMA X5.1 (American Furniture Manufacturers Association standard), EN 1335 (European office furniture standard).

- •Application Scenarios:

- •Manufacturers: Validate leg design feasibility during R&D and conduct pre-production sampling to ensure consistent quality;

- •Quality Inspection Agencies: Third-party labs certify office chairs against compliance standards;

- •Purchasers: Evaluate sample durability to reduce procurement risks.

V. Equipment Features and Selection Considerations

- •Features: High automation (reduces manual intervention), precise loading control (avoids overloading/underloading), and scalability (some models support multi-station simultaneous testing).

- •Key Selection Parameters:

- •Maximum loading capacity (must cover the target leg’s weight limit, e.g., 150–500kgf);

- •Loading frequency range (typically 1–5Hz);

- •Maximum cycle count (recommended ≥100,000 times);

- •Compatibility with leg types (e.g., star bases, caster bases, single-column legs).