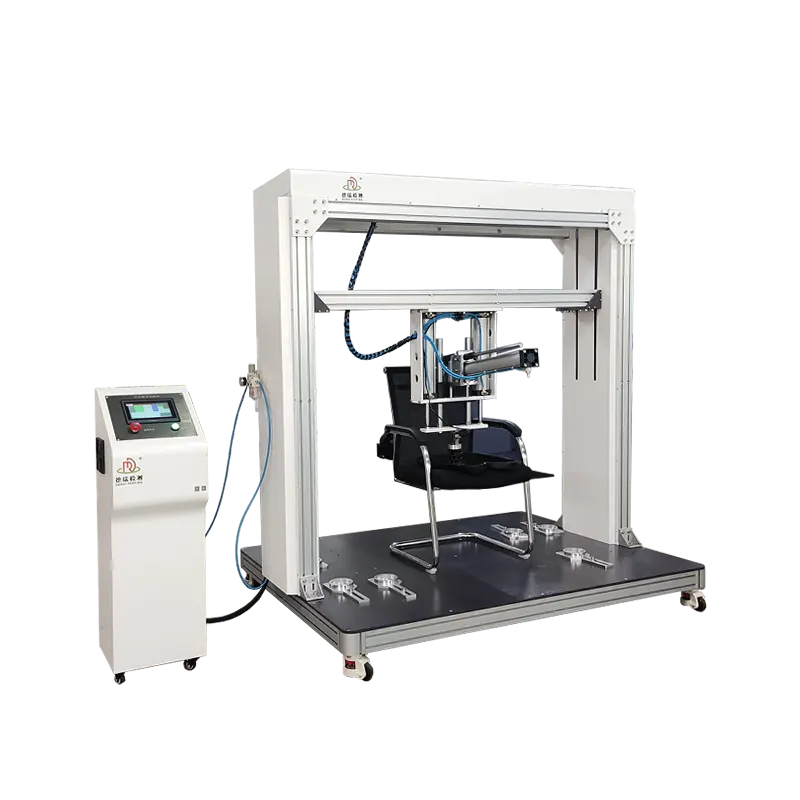

A chair and stool stability tester is a specialized testing device designed to evaluate the anti-tipping performance of chairs and stools (such as office chairs, dining chairs, lounge chairs, and children's chairs) under various usage conditions. Its primary purpose is to assess whether the product meets relevant safety standards (e.g., GB/T 10357 series, EN 12520, BIFMA X5.1), ensuring it does not tip over unexpectedly during normal or extreme use, thereby safeguarding user safety.

I. Core Functions and Testing Principles

This equipment simulates real-world usage scenarios—such as static sitting pressure, dynamic impacts, and lateral/rearward force application—by applying controlled external forces to the chair or stool. It then observes whether tipping occurs and records critical parameters (e.g., maximum tilt angle, applied force) at the threshold of instability.

Basic Testing Logic: A controllable external force (vertical/horizontal) is applied to specific parts of the chair/stool (e.g., seat surface, backrest, armrests, or other targeted areas). The support legs (or wheels) are monitored to determine if any completely lose contact with the ground (or if wheels become suspended and fail to provide support). If so, the chair/stool is deemed "unstable."

II. Key Testing Items

Based on different standards and usage scenarios, common tests include:

- 1.Static Stability Tests (Simulating Static Sitting Pressure)

- •Forward Stability: A vertical downward force is applied to the front edge of the seat (simulating a user leaning forward), checking if the front legs lift off the ground.

- •Rearward Stability: A vertical or diagonal force is applied to the backrest or rear seat area (simulating a user leaning back against the backrest), checking if the rear legs lift off the ground.

- •Lateral Stability: A horizontal or vertical force is applied to one side (left/right) of the seat surface (simulating a user sitting asymmetrically or shifting body weight), checking if the corresponding support leg lifts off the ground.

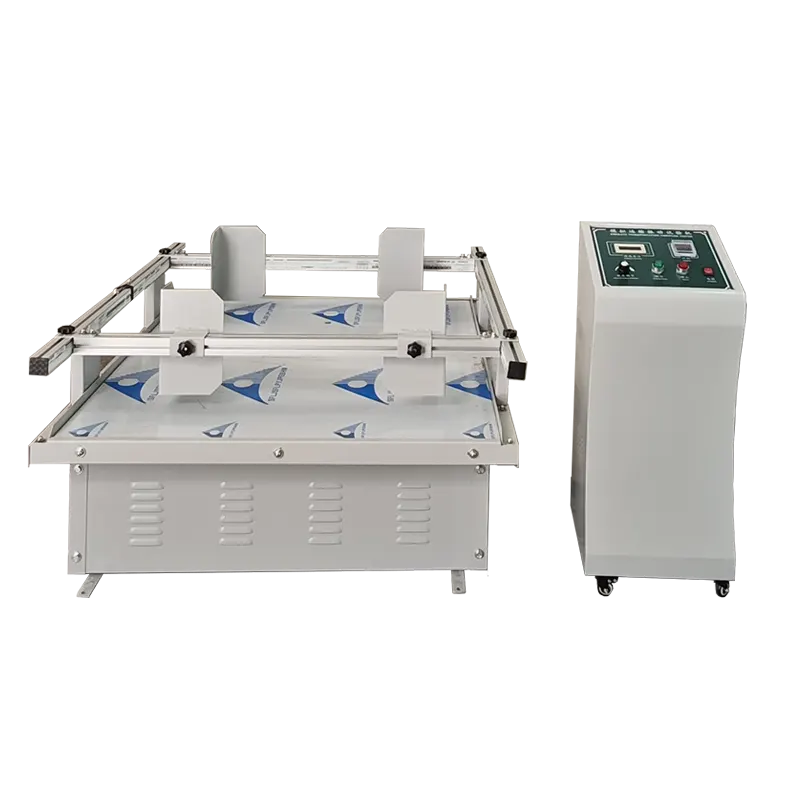

- 2.Dynamic Stability Tests (Simulating Dynamic Usage)

- •Impact Loading: A rapid instantaneous force is applied (e.g., simulating sudden standing, jumping, or a child bouncing), evaluating the chair/stool’s immediate resistance to tipping.

- •Cyclic Loading: Repeated application of a standardized force for a set number of cycles (simulating long-term use and potential stability degradation over time).

- 3.Special Scenario Tests (For Specific Types of Chairs/Stools)

- •Armrest-Equipped Chairs: Tests the impact of armrest force application on stability (e.g., when a user grips the armrests forcefully).

- •Adjustable Chairs (e.g., height-adjustable, swivel chairs): Tests stability under various adjustment states (e.g., highest/lowest height, swivel locked/unlocked).

- •Children’s Chairs: Applies stricter tipping thresholds due to lighter body weight and larger movement amplitudes (specific to child safety requirements).

III. Key Components

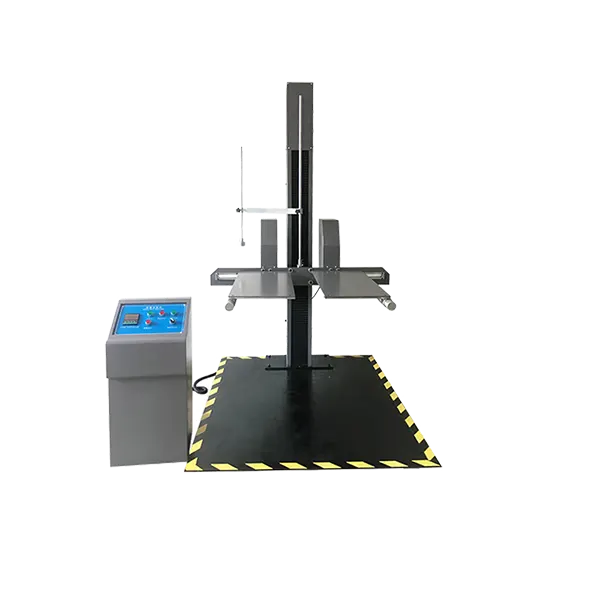

- 1.Loading System

- •Force Application Device: Typically uses electric push rods, hydraulic cylinders, or pneumatic cylinders to precisely control the magnitude (accuracy ±1%) and direction (vertical/horizontal/diagonal) of the applied force. Some devices support multi-directional simultaneous loading.

- •Human Body Simulation Modules: Includes weights (e.g., 50kg/75kg/100kg, simulating human body weight per standard requirements) or pressure sensors (to monitor real-time applied force data).

- 2.Fixation and Support Structure

- •Test Platform: A rigid base (e.g., cast iron or steel structure) ensures no displacement or deformation during testing.

- •Chair/Stool Fixation Device: Adjustable clamps or positioning brackets secure the test specimen (accommodating various sizes, e.g., seat width 300–600mm, height 300–500mm). Some devices include slide rails to simulate wheel movement (testing mobility stability).

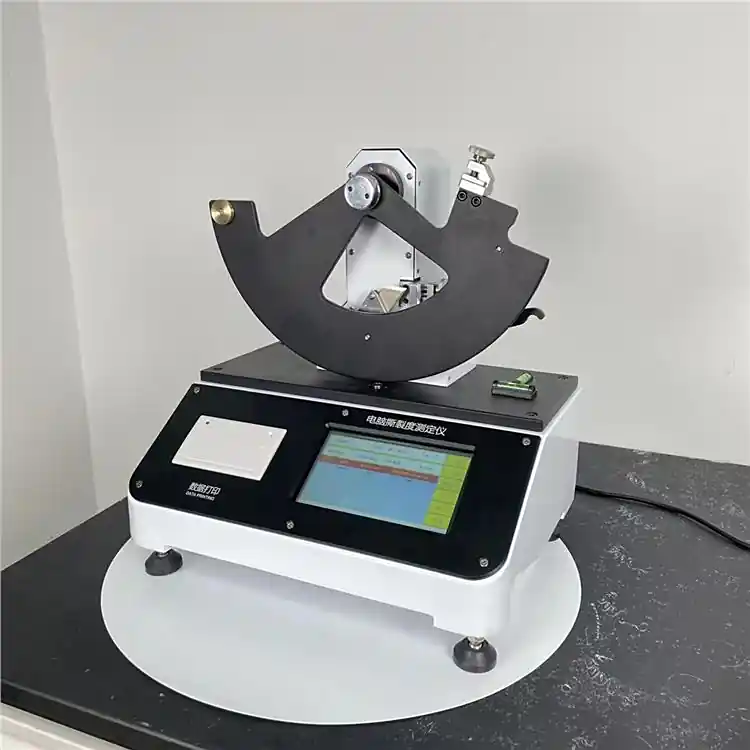

- 3.Monitoring and Control System

- •Sensors: Force sensors (measure applied force), displacement sensors (monitor support leg lift-off distance or tilt angle), and pressure distribution sensors (analyze seat surface force uniformity).

- •Data Acquisition System: Real-time recording of applied force curves, tilt angle changes, and critical tipping states, with support for exporting reports (e.g., Excel/PDF formats).

- •Control Panel: Human-machine interface (touchscreen or computer software) allows setting test parameters (force value, loading speed, duration, etc.) and initiating automated test sequences.

- 4.Safety Protection Devices

- •Guardrails/enclosures (prevent ejected tipped chairs/stools from injuring personnel), emergency stop buttons (halt testing immediately in critical situations), and overload protection (prevents equipment damage from excessive loads).

IV. Applicable Standards

Different regions and use cases require compliance with corresponding stability standards. Common standards include:

- •China: GB/T 10357.1-2013 Furniture Mechanical Performance Testing Part 1: Strength and Durability of Tables(partial clauses), GB/T 10357.3-2013 Part 3: Strength and Durability of Chairs and Stools(primary reference).

- •International: EN 12520 Furniture – Strength and Durability of Domestic Seating, BIFMA X5.1 Office Chair Performance Standard(U.S.), ISO 7174 Furniture – Stability Testing of Chairs.

- •Special Requirements: Children’s furniture must comply with additional stability clauses (e.g., "resistance to tipping from push/pull forces") in GB 28007 General Technical Requirements for Children’s Furniture.

V. Application Scenarios

- •Furniture Manufacturers: Used during R&D to validate stability, optimize structural design (e.g., adjusting base dimensions, adding non-slip pads, improving weight distribution).

- •Quality Testing Agencies: Conduct sampling inspections on marketed chair/stool products to determine compliance with safety standards (issuing test reports).

- •Laboratory Research: Universities/research institutes perform foundational studies on furniture mechanical performance (e.g., effects of materials and structures on stability).

VI. Purchasing Considerations

When selecting a chair and stool stability tester, focus on:

- 1.Testing Scope: Ability to cover target chair/stool types (e.g., office chairs, children’s chairs, high-legged stools) and key test items required by standards (forward/rearward/lateral stability).

- 2.Precision and Automation: Applied force precision (±1% or better), sensor resolution (e.g., 0.1N), and support for automated loading/data recording (reducing human error).

- 3.Compatibility: Adaptability to different chair/stool sizes/weights (via adjustable clamps or platform extensions).

- 4.Brand and Service: Prioritize manufacturers with experience in furniture testing equipment (e.g., providing standard configuration solutions, after-sales maintenance, and calibration services).

By testing with this equipment, manufacturers can identify design flaws (e.g., undersized bases, high centers of gravity) early, improving product safety and avoiding recalls or legal risks caused by tipping accidents.